Titanium alloy wire high-temperature drawing water-based lubricant and preparation method thereof

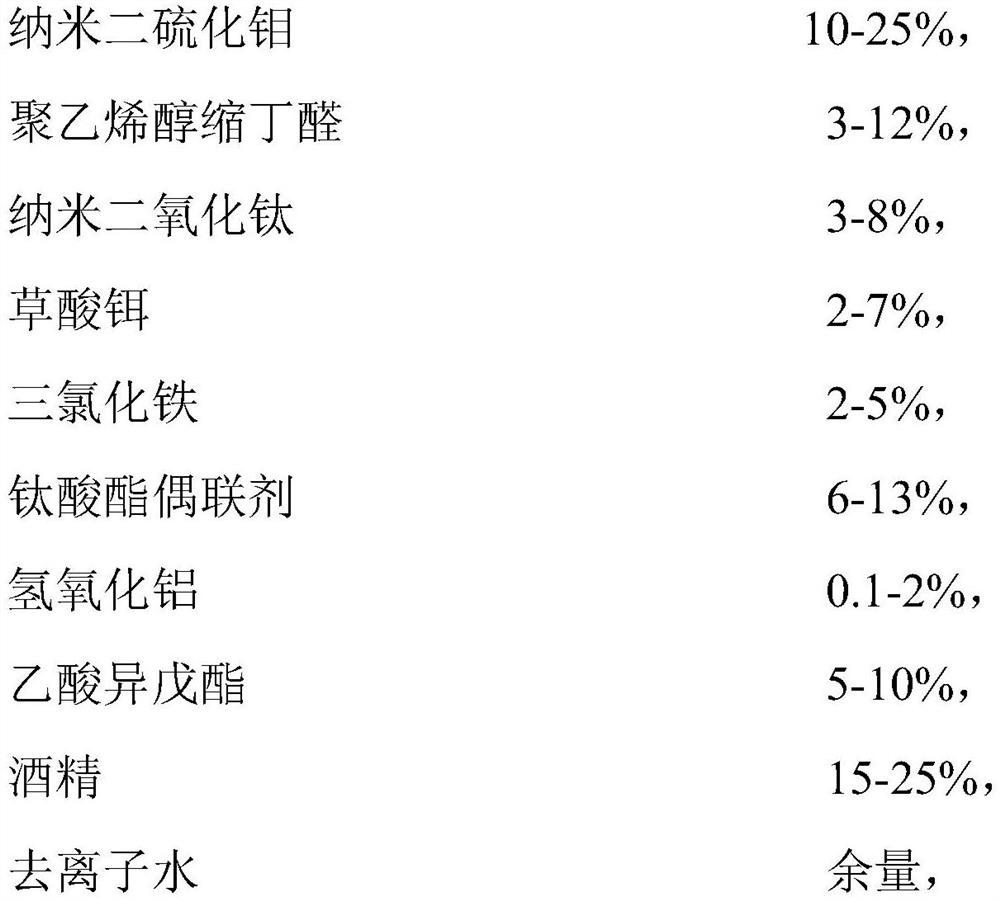

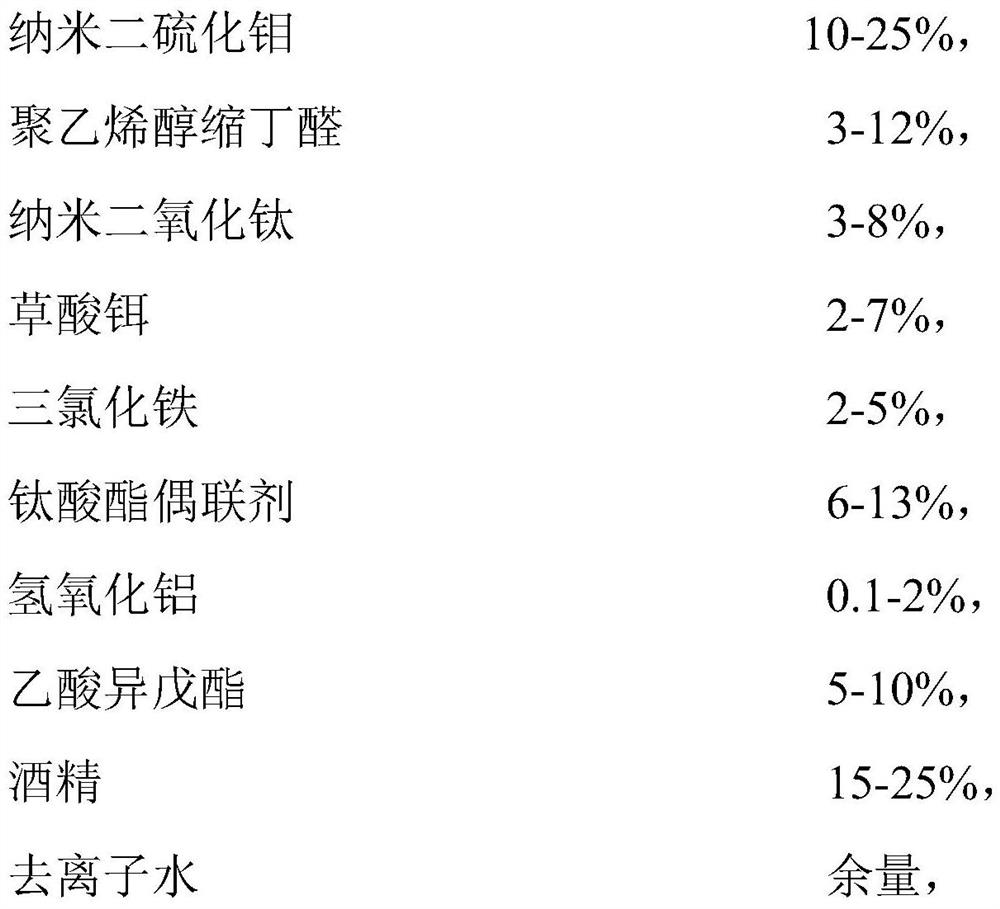

A technology of water-based lubricant and titanium alloy wire, which can be used in lubricating compositions, petroleum industry, etc., and can solve the problems of sticking between drawing dies and drawing metal blanks, and easy to lose lubricating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

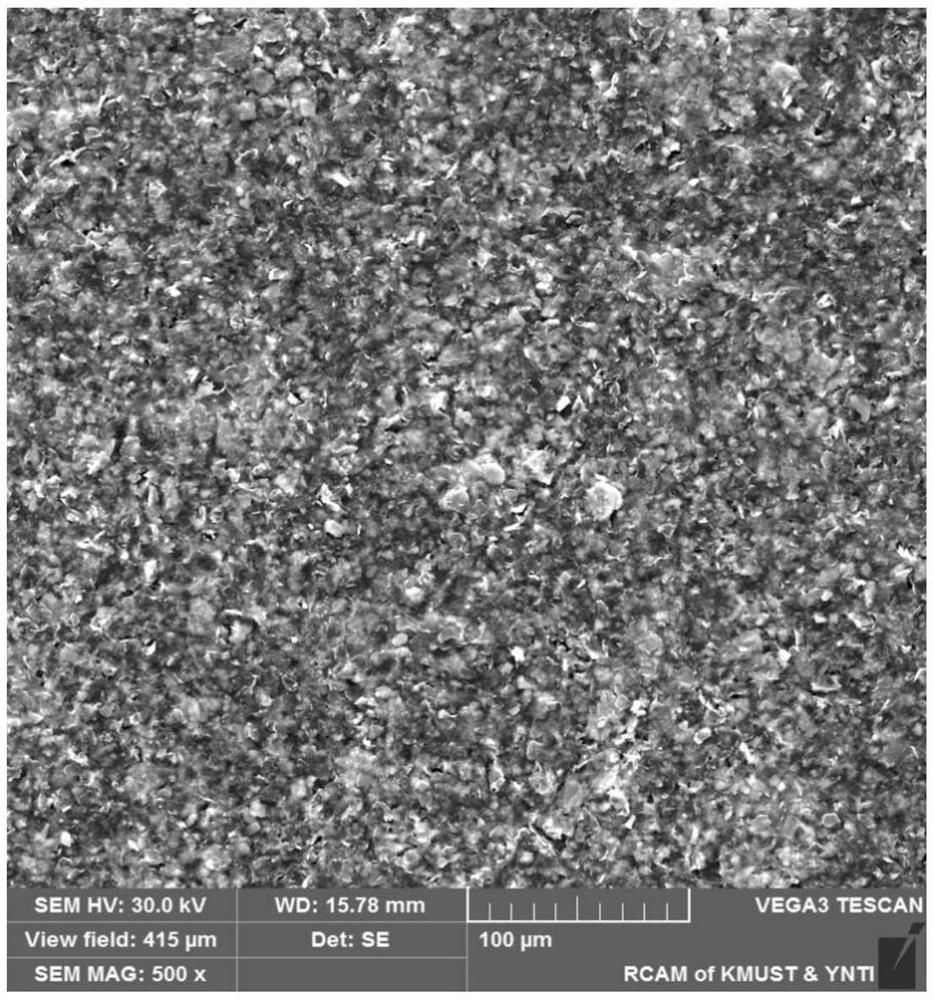

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of a water-based lubricant for high-temperature drawing of titanium alloy wire, comprising the following steps:

[0025] Step 1. Add nano-molybdenum disulfide, nano-titanium dioxide, and erbium oxalate into deionized water dissolved in alcohol, and stir at 60-90°C for 30-50 minutes to obtain the first mixed solution;

[0026] Step 2, adding the titanate coupling agent and ferric chloride to the first mixed solution obtained in step 1, and stirring for 20-50 minutes to obtain the second mixed solution;

[0027] Step 3. Add isoamyl acetate, polyvinyl butyral, and aluminum hydroxide to the secondary mixed solution obtained in step 2, stir for 20-45 minutes to obtain a mixed solution, and cool to room temperature to obtain a water-based lubricant.

[0028] The lubricant of the present invention is suitable for high-temperature drawing, has good film-forming properties and a continuous lubricating film; it can be used ...

Embodiment 1

[0030] (1) Add 10 g of nano-molybdenum disulfide, 5 g of nano-titanium dioxide, and 2 g of erbium oxalate into deionized water with 17 g of alcohol, and stir at 60° C. for 30 minutes to obtain the first mixed solution;

[0031] (2) Add 7g of titanate coupling agent and 2g of ferric chloride to the mixed solution obtained in step 1 for the first time, and stir for 20min to obtain the mixed solution for the second time;

[0032] (3) Finally, add 8.5g of isoamyl acetate, 5g of polyvinyl butyral, and 1g of aluminum hydroxide to the secondary mixing solution, stir for 20 minutes, mix evenly and cool to room temperature to obtain a water-based lubricant.

[0033] Wherein, the particle size of the nano-molybdenum disulfide is in the range of 20-60 nm, and the particle size of the nano-titanium dioxide is in the range of 40-70 nm.

Embodiment 2

[0035] (1) Add 15g of nano-molybdenum disulfide, 3g of nano-titanium dioxide, and 3g of erbium oxalate into deionized water with 20g of alcohol, stir at 90°C for 50min to obtain the first mixed solution;

[0036] (2) Add 6g of titanate coupling agent and 3g of ferric chloride to the first mixed solution gained in step 1, and stir for 50min to obtain the second mixed solution;

[0037] (3) Finally, add 10 g of isoamyl acetate, 6 g of polyvinyl butyral, and 1.5 g of aluminum hydroxide to the secondary mixing solution, stir for 45 minutes, mix evenly and cool to room temperature to obtain a water-based lubricant.

[0038] Wherein, the particle size of the nano-molybdenum disulfide is in the range of 20-60 nm, and the particle size of the nano-titanium dioxide is in the range of 40-70 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com