A kind of insulating material with high glass transition temperature and high temperature adhesiveness and preparation method thereof

A transition temperature, high vitrification technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems that the electrical industry cannot meet the requirements, and reduce curing time and affinity. Improved, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of dispersant: Add 30g of carboxymethyl cellulose to an appropriate amount of deionized water, stir at room temperature until completely dissolved; adjust the pH of the solution to 5-6 with 10% acetic acid solution, then add 1g of ferrocene and 20g of tartaric acid , heated up to 70°C and stirred for 2 hours, and an oily substance appeared in the reaction system; cooled to 35°C, added 2g of sodium chloride and 2g of sodium glycocholate and stirred for 0.5h; cooled to room temperature, separated the oily substance, evaporated and crystallized to obtain carboxylate Methylcellulose / Tartrate.

[0035] Preparation of insulating material:

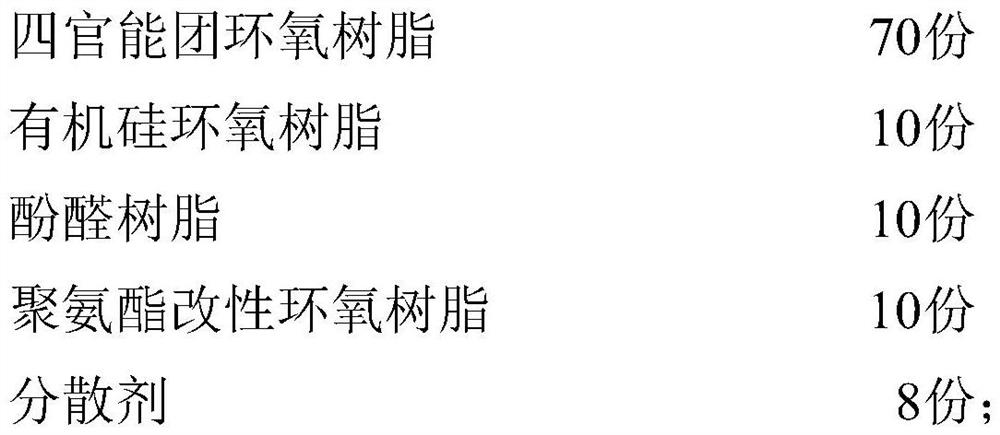

[0036] (1) Preparation of modified resin composition: Add 70g of Huntsman's four-functional epoxy resin into a high-speed dispersion storage tank, preheat to 80°C; then add 10g of Huntsman's organosilicon epoxy resin, 10g of phenolic resin 10g of polyurethane modified epoxy resin SL3451, stirred and mixed at 400r / min for 1h, c...

Embodiment 2

[0041] Preparation of dispersant: Add 35g of carboxymethyl cellulose to an appropriate amount of deionized water, stir at room temperature until completely dissolved; adjust the pH of the solution to 5-6 with 10% acetic acid solution, then add 1g of ferrocene and 22g of tartaric acid , heated up to 70°C and stirred for 2 hours, and an oily substance appeared in the reaction system; cooled to 35°C, added 2g of sodium chloride and 2g of sodium glycocholate and stirred for 0.5h; cooled to room temperature, separated the oily substance, evaporated and crystallized to obtain carboxylate Methylcellulose / Tartrate.

[0042] Preparation of insulating material:

[0043] (1) Preparation of modified resin composition: Add 70g of Huntsman's four-functional epoxy resin into a high-speed dispersion storage tank, preheat to 80°C; then add 10g of Huntsman's organosilicon epoxy resin, 10g of phenolic resin 10g of polyurethane modified epoxy resin SL3451, stirred and mixed at 400r / min for 1h, c...

Embodiment 3

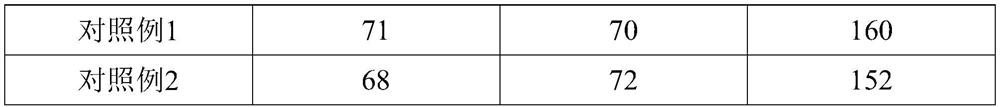

[0061] Based on Example 2, a comparative example 1 using an acrylate dispersant and a comparative example 2 without modifying the metal silicon powder are set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com