Insulating material with high glass transition temperature and high-temperature cohesiveness and preparation method of insulating material

A transition temperature, high vitrification technology, applied in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems that the electrical industry cannot meet the requirements, reduce curing time, improve high temperature viscosity The effect of improving junction and physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of dispersant: Add 30g of carboxymethyl cellulose to an appropriate amount of deionized water, stir at room temperature until completely dissolved; adjust the pH of the solution to 5-6 with 10% acetic acid solution, then add 1g of ferrocene and 20g of tartaric acid , heated up to 70°C and stirred for 2 hours, and an oily substance appeared in the reaction system; cooled to 35°C, added 2g of sodium chloride and 2g of sodium glycocholate and stirred for 0.5h; cooled to room temperature, separated the oily substance, evaporated and crystallized to obtain carboxylate Methylcellulose / Tartrate.

[0035] Preparation of insulating material:

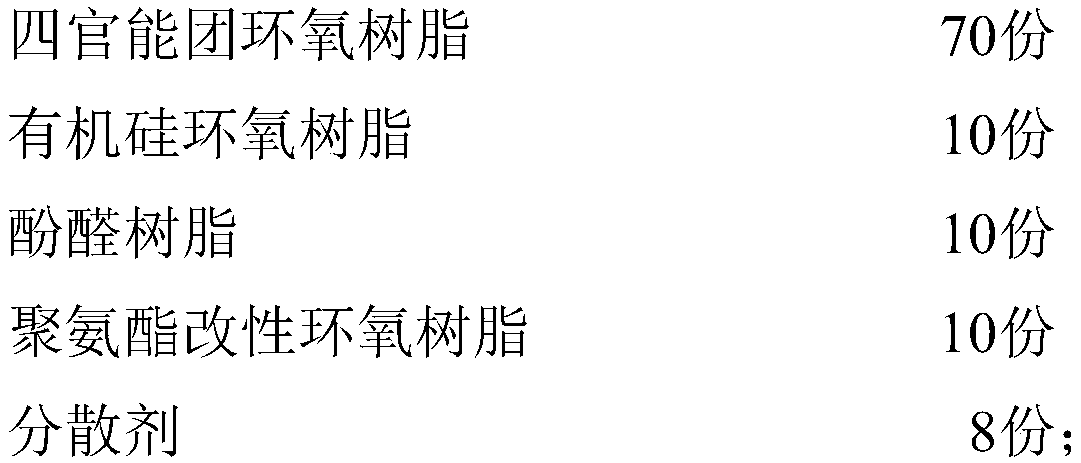

[0036] (1) Preparation of modified resin composition: Add 70g of Huntsman's four-functional epoxy resin into a high-speed dispersion storage tank, preheat to 80°C; then add 10g of Huntsman's organosilicon epoxy resin, 10g of phenolic resin 10g of polyurethane modified epoxy resin SL3451, stirred and mixed at 400r / min for 1h, c...

Embodiment 2

[0041] Preparation of dispersant: Add 35g of carboxymethyl cellulose to an appropriate amount of deionized water, stir at room temperature until completely dissolved; adjust the pH of the solution to 5-6 with 10% acetic acid solution, then add 1g of ferrocene and 22g of tartaric acid , heated up to 70°C and stirred for 2 hours, and an oily substance appeared in the reaction system; cooled to 35°C, added 2g of sodium chloride and 2g of sodium glycocholate and stirred for 0.5h; cooled to room temperature, separated the oily substance, evaporated and crystallized to obtain carboxylate Methylcellulose / Tartrate.

[0042] Preparation of insulating material:

[0043] (1) Preparation of modified resin composition: Add 70g of Huntsman's four-functional epoxy resin into a high-speed dispersion storage tank, preheat to 80°C; then add 10g of Huntsman's organosilicon epoxy resin, 10g of phenolic resin 10g of polyurethane modified epoxy resin SL3451, stirred and mixed at 400r / min for 1h, c...

Embodiment 3

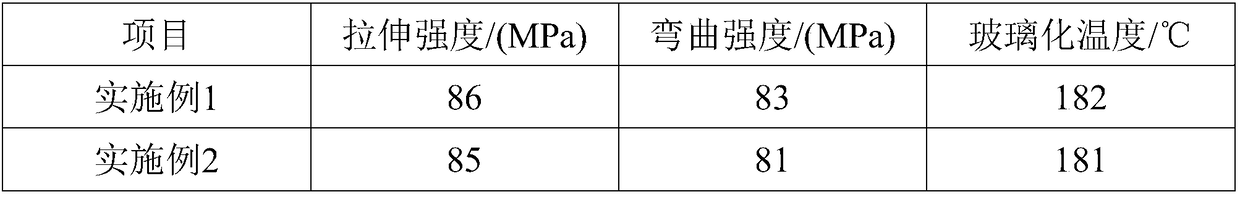

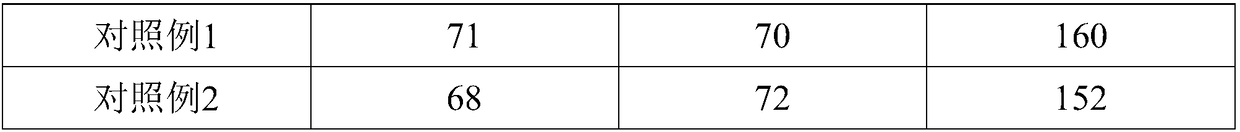

[0061] Based on Example 2, a comparative example 1 using an acrylate dispersant and a comparative example 2 without modifying the metal silicon powder are set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com