A kind of efficient preparation method of vegetable oil

A vegetable oil, high-efficiency technology, applied in the fields of fat oil/fat refining, food science, edible oil/fat, etc., can solve the problems of reducing the nutritional value of vegetable oil, unable to produce high-quality vegetable oil, and high refining consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

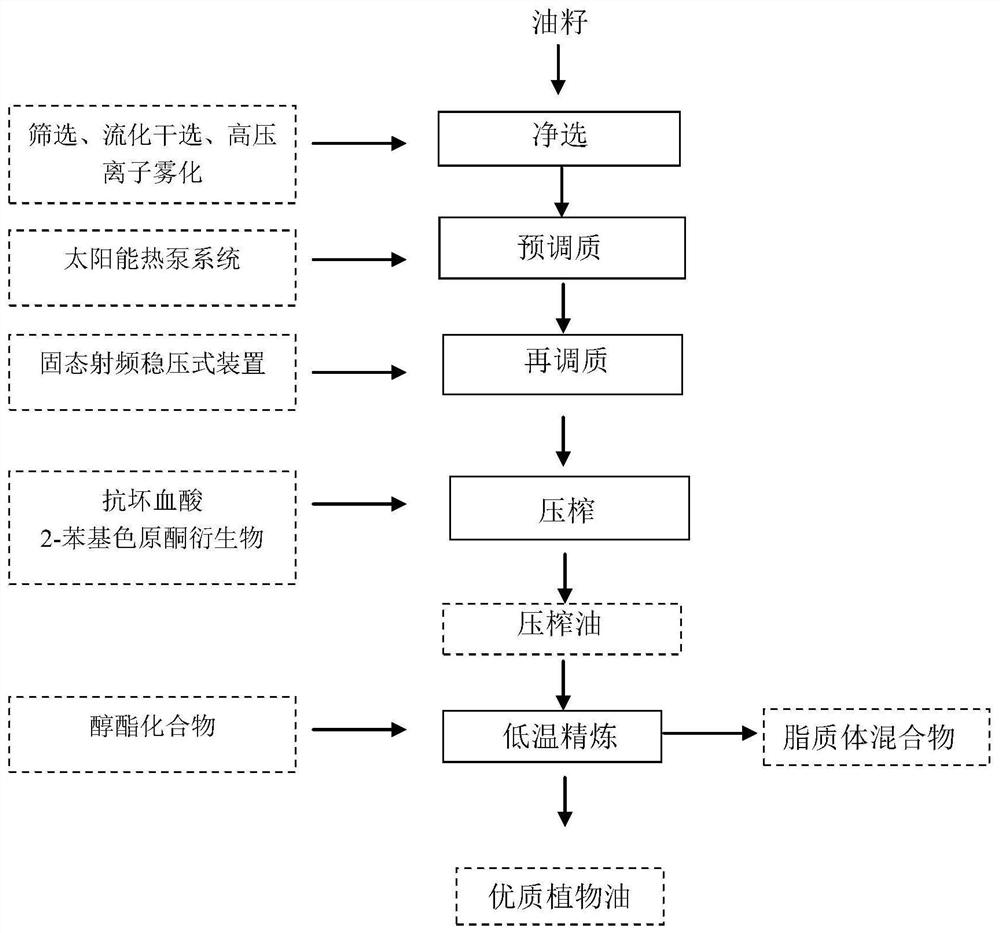

Method used

Image

Examples

Embodiment 1

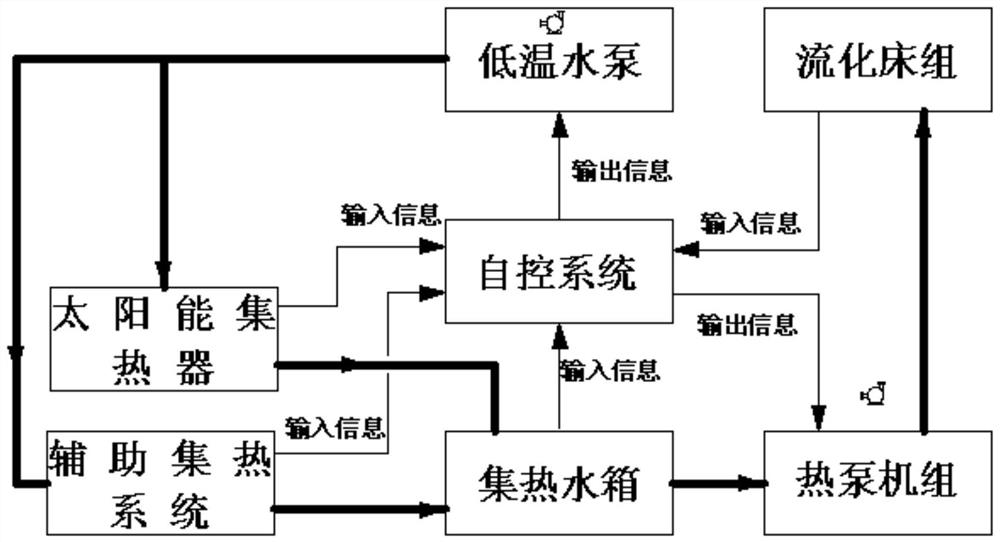

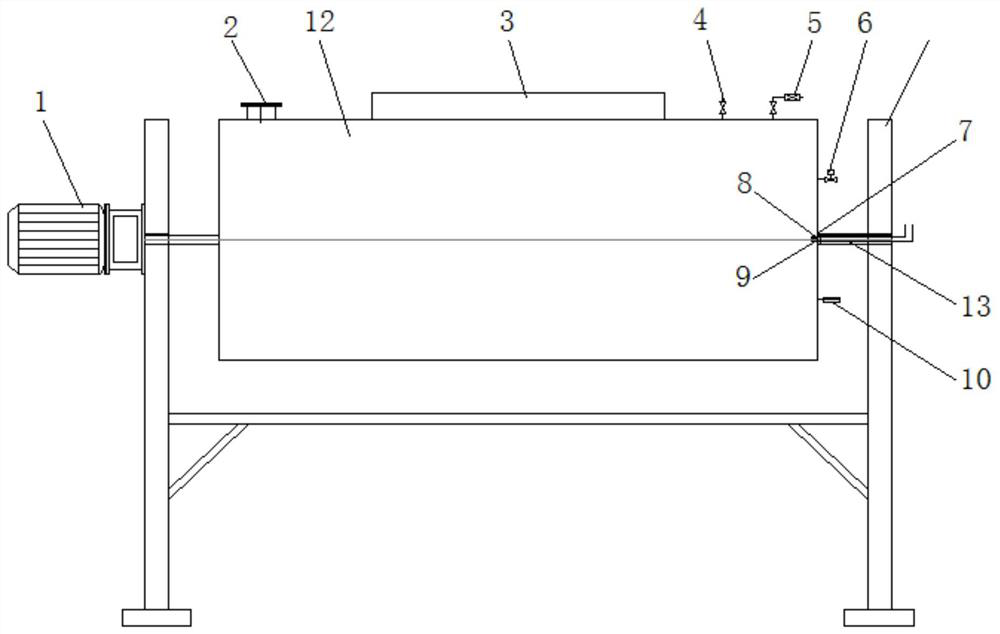

[0043] Using rapeseed as raw material, firstly use screening and cleaning, the screened oilseeds are fed into the fluidized bed, and the pressurized gas is evenly transported into the fluidized bed through the air distribution plate with a certain pressure drop, so that the expansion ratio of the mixture of oilseed and impurities is 12. %, the medium with a specific gravity smaller than the oilseed is separated from the top of the fluidized bed, and the medium with a larger specific gravity than the oilseed is separated from the bottom of the fluidized bed, and the obtained rapeseed has an impurity content of 0.02%. The proportion of seeds is 0.01%. The separated rapeseed and dust-laden air enter the chamber-type high-pressure ion atomization device respectively, the atomization pressure is 15MPa, and the water mist droplets are 5μm. The rapeseed and dust-laden air are in different chambers, and the clean rapeseed and air are discharged respectively. . The clean rapeseed is i...

Embodiment 2

[0045] Using camellia seeds as raw material, firstly use screening and cleaning, the screened oil seeds are sent to the fluidized bed, and the pressurized gas is evenly transported into the fluidized bed through the air distribution plate with a certain pressure drop, so that the expansion ratio of the mixture of oil seeds and impurities is 5 %, the medium with a specific gravity smaller than the oilseed is separated from the top of the fluidized bed, and the medium with a larger specific gravity than the oilseed is separated from the bottom of the fluidized bed, and the obtained camellia seed has an impurity content of 0.2%. The proportion of seeds is 0.1%. The separated camellia seeds and dust-laden air enter the chamber-type high-pressure ion atomization device respectively, the atomization pressure is 5MPa, and the water mist droplets are 50μm, in which the camellia seeds and the dust-laden air are in different compartments, and the clean camellia seeds and air are discharg...

Embodiment 3

[0047] Using sesame as raw material, firstly use screening and cleaning, the screened oilseeds are fed into the fluidized bed, and the pressurized gas is evenly transported into the fluidized bed through the air distribution plate with a certain pressure drop, so that the expansion rate of the mixture of oilseeds and impurities is 8.5% , the medium with a specific gravity smaller than that of the oilseed is separated from the top of the fluidized bed, and the medium with a larger specific gravity than the oilseed is separated from the bottom of the fluidized bed. The impurity content of the obtained sesame is 0.11%. 0.05%. The separated sesame and dust-laden air enter the chamber-type high-pressure ion atomization device respectively. The atomization pressure is 10MPa, and the water mist droplets are 26μm. The sesame and dust-laden air are in different chambers, and clean sesame and air are discharged respectively. The clean sesame is fed into the fluidized bed group of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com