A kind of low expansion alloy and preparation method thereof

A low-expansion alloy and alloy ingot technology, applied in the field of low-expansion alloys, can solve the problems of strengthening low-expansion alloys, achieve the effect of optimizing alloy strength and eliminating residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment prepares a kind of low-expansion alloy, specifically comprises the following steps:

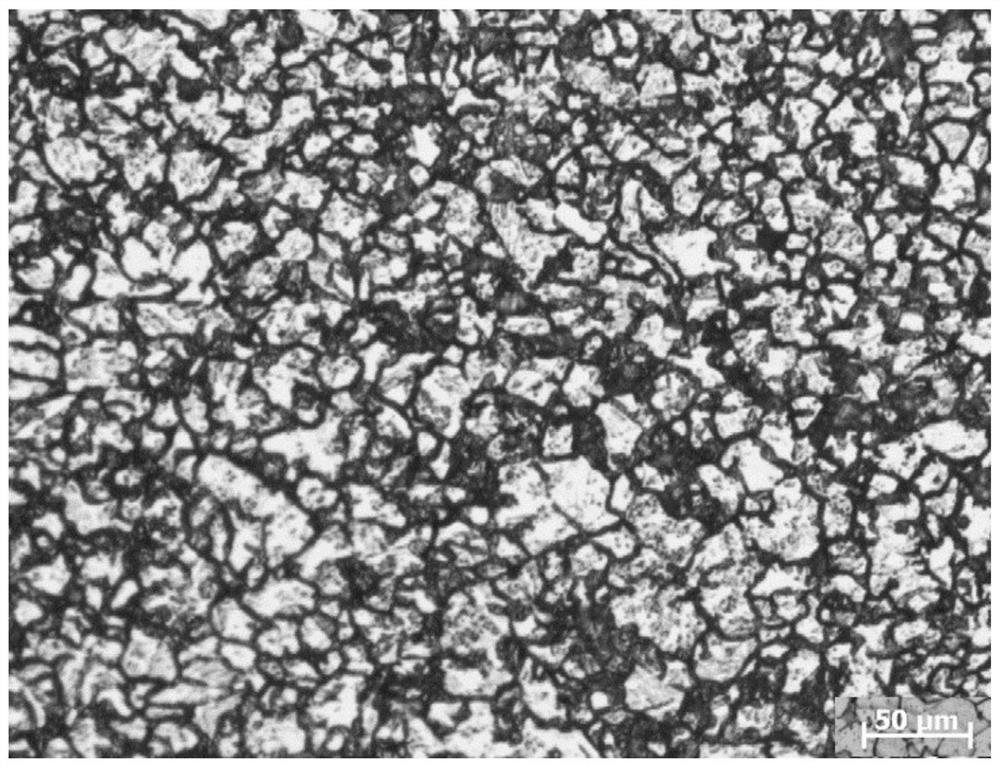

[0056] Preparation of low-expansion alloy body (ie, hot-rolled plate): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1450 ° C, and the vacuum degree of the melting furnace is 0.2×10 -2 Pa, after all the raw materials are melted, refine at a temperature of 1800°C for 5 minutes, then pass in an inert gas, and cast a crucible into an ingot (alloy ingot). Wherein, the formula of raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1150°C and kept at this temperature for 4 hours for homogenization. Carry out blanking on the hot rolling mill subsequently, wherein, the starting rolling temperature is 1150 ℃, the total reduction rate is 95%, the final rolling temperature is 950 ℃, and when rolling to 3mm thic...

Embodiment 2

[0062] The present embodiment prepares a kind of low-expansion alloy, specifically comprises the following steps:

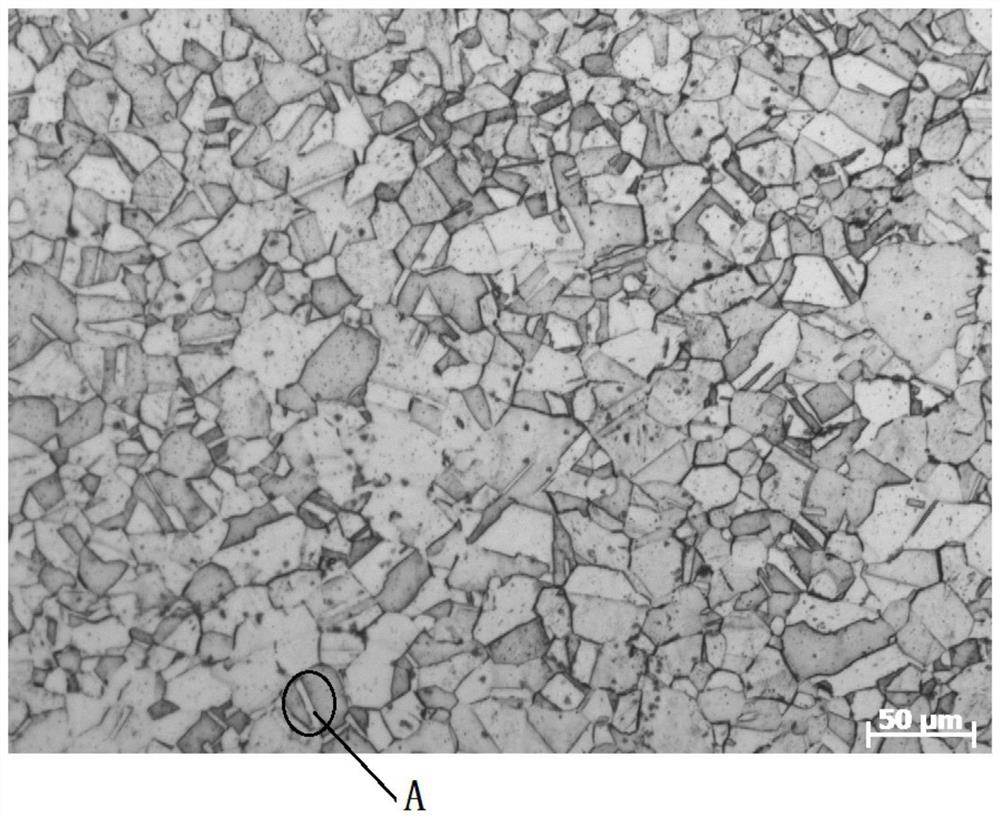

[0063] Preparation of low-expansion alloy body (ie, hot-rolled plate): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1500 ° C, and the vacuum degree of the melting furnace is 0.4×10 -2 Pa, after all the raw materials are melted, it is refined at a temperature of 1600°C for 6 minutes, and then an inert gas is introduced, and a crucible is cast into an ingot (ie, an alloy ingot). Wherein, the formula of raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1180°C and kept at this temperature for 3 hours for homogenization. Carry out blanking on the hot rolling mill subsequently, wherein, the starting rolling temperature is 1180 ℃, the total reduction rate is 80%, the final rolling temperature is 980 ℃, a...

Embodiment 3

[0069] The present embodiment prepares a kind of low-expansion alloy, specifically comprises the following steps:

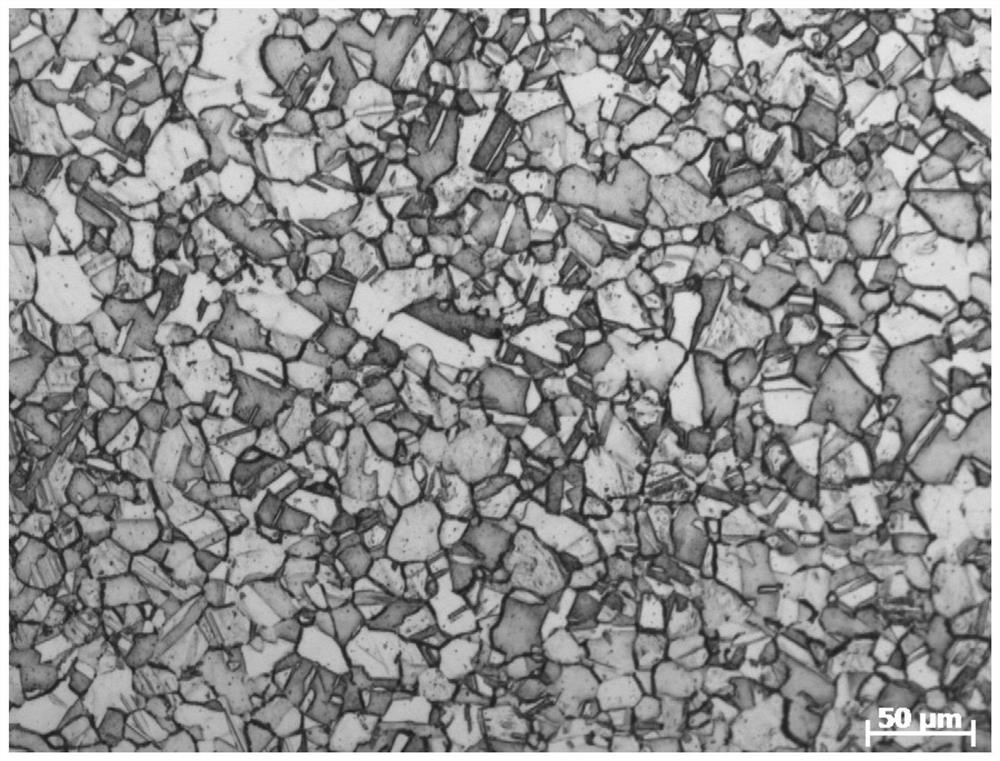

[0070] Preparation of low-expansion alloy body (ie, hot-rolled plate): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1550 ° C, and the vacuum degree of the melting furnace is 0.6×10 -2 Pa, after all the raw materials are melted, it is refined at a temperature of 1550°C for 8 minutes, and then an inert gas is introduced, and a crucible is cast into an ingot (ie, an alloy ingot). Wherein, the formula of raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1200°C and kept at this temperature for 2 hours for homogenization. Carry out blanking on the hot rolling mill subsequently, wherein, the starting rolling temperature is 1200 ℃, the total reduction rate is 60%, the final rolling temperature is 900 ℃, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com