Thermal processing method of low-carbon high-alloy steel bearing ring

A bearing ring, high alloy steel technology, applied in manufacturing tools, metal material coating processes, heat treatment furnaces, etc., can solve the problem that aviation bearing materials cannot meet bearing performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: In this embodiment, a method for thermal processing of a bearing ring made of low-carbon high-alloy steel is carried out according to the following steps:

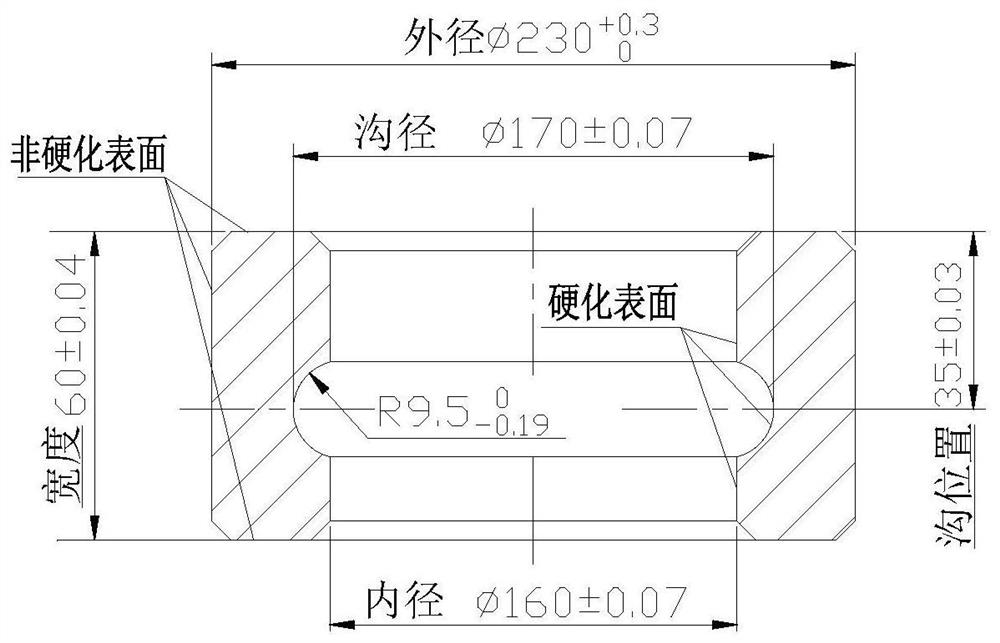

[0021] 1. Process low-carbon high-alloy steel into bearing rings to be carburized;

[0022] 2. Carburizing: Put the bearing ring into the vacuum carburizing furnace, vacuumize, heat, low-temperature pulse carburizing, heating diffusion, high-temperature pulse carburizing, and air-cooling to get the carburized ring;

[0023] 3. Perform stress relief annealing on the ring after carburizing to obtain the bearing ring after stress relief annealing;

[0024] 4. Machining the bearing ring after stress relief annealing, removing the carburized layer on the outer surface and end face of the bearing ring, and obtaining the machined bearing ring;

[0025] 5. Carry out vacuum quenching and air cooling to the machined bearing ring to obtain the quenched bearing ring;

[0026] Sixth, the quenched bearing ring is ...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass fraction of C in the low-carbon high-alloy steel is 0.1-0.2%, the mass fraction of Cr is 11.0-17.0%, and the mass fraction of Mo is 3.0- 6.0%, and the mass fraction of Co is 11.0-13.0%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the method of carburizing in step two is: the bearing ring after cleaning, drying and drying is sent into the furnace and vacuumized, and the pressure is 3-5mbar ;Under the condition of heating rate of 10℃ / min, heat the bearing ring to 650-750℃, keep it warm for 20-40min, then continue to heat to the low-temperature carburizing temperature of 820℃-1000℃, keep it warm for 20-40min, then carry out low-temperature pulse Carburizing, repeat low-temperature pulse carburizing for 18-80 times, then continue to heat up to 960-1000°C, the heating rate is 10°C / min, after holding for 10-30min, start high-temperature pulse carburizing, repeat high-temperature pulse carburizing operation for 10- 40 times, and then air-cooled out of the furnace, the cooling pressure is 1 to 5 Bar. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seepage depth | aaaaa | aaaaa |

| Heart hardness | aaaaa | aaaaa |

| Seepage depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com