Online recycling method of high-wet-strength broke

A wet-strength paper and strength technology, applied in the field of papermaking, can solve the problems of paper strength reduction, fiber loss, and inability to effectively reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

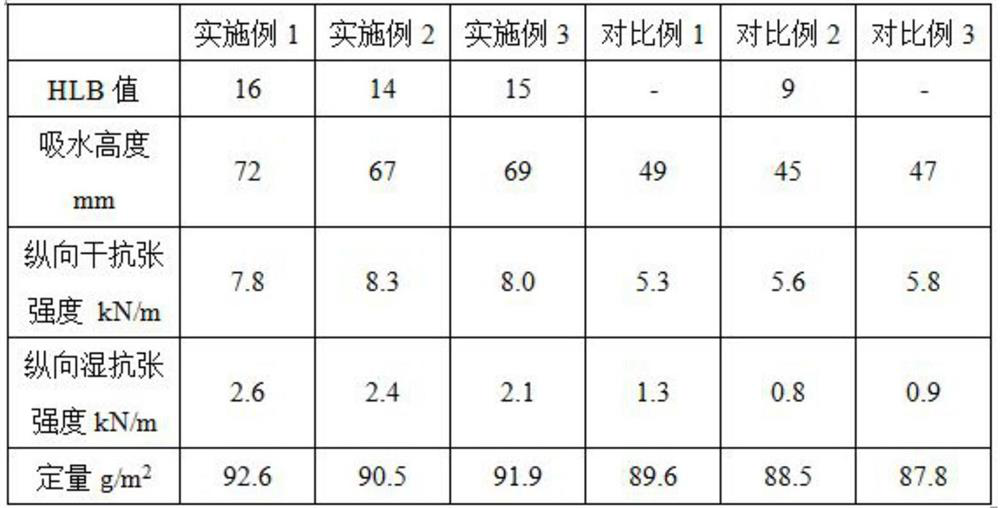

Examples

Embodiment 1

[0028] An online recycling method for broken paper with high wet strength, comprising the following steps:

[0029] Step 1: Add the retention aid anion CMC into the production of wet strength paper, the addition amount is 4kg / t paper;

[0030] Step 2: Collect the broken paper produced in the production process of wet strength paper, and use a dry broken paper treatment steamer with agitator for centralized treatment within 2 hours. The maximum temperature is controlled at 95°C and kept for 2 hours until the paper pieces are completely disintegrated. The concentration is controlled at 15%, and the broken paper includes dried and calendered broken paper and white paper produced during production;

[0031] Step 3: Send the side of the rewinding paper to the hydraulic pulper at the head of the paper machine for disintegration, and the disintegration time is 3 hours;

[0032] Step 4: Send the paper pieces screened out by the screening system of the paper machine directly to the fr...

Embodiment 2

[0036] An online recycling method for broken paper with high wet strength, comprising the following steps:

[0037] Step 1: Add the retention aid anion CMC into the production of wet strength paper, the addition amount is 2kg / t paper;

[0038] Step 2: Collect the broken paper produced in the production process of wet strength paper, and use a dry broken paper treatment steamer with agitator for centralized treatment within 2 hours. The maximum temperature is controlled at 98°C and kept for 4 hours until the paper pieces are completely disintegrated. The concentration is controlled at 10%, and the broken paper includes dried and calendered broken paper and white paper produced during production;

[0039] Step 3: Send the side of the rewinding paper to the hydraulic pulper at the head of the paper machine for disintegration, and the disintegration time is 5 hours;

[0040] Step 4: Send the paper pieces screened out by the paper machine screening system directly to the front slo...

Embodiment 3

[0044] An online recycling method for broken paper with high wet strength, comprising the following steps:

[0045] Step 1: Add the retention aid anion CMC into the production of wet strength paper, the addition amount is 6kg / t paper;

[0046] Step 2: Collect the broken paper produced in the production process of wet strength paper, and use a dry broken paper treatment steamer with agitator for centralized treatment within 2 hours. The maximum temperature is controlled at 90°C and kept for 3 hours until the paper pieces are completely disintegrated. The concentration is controlled at 20%, and the broken paper includes dried and calendered broken paper and white paper produced during production;

[0047] Step 3: Send the side of the rewinding paper to the hydraulic pulper at the head of the paper machine for disintegration, and the disintegration time is 4 hours;

[0048]Step 4: Send the paper pieces screened out by the paper machine screening system directly to the front slot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com