Heat recovery closed circulation rice drying system and method

A technology of closed circulation and drying system, which is applied in the direction of drying, drying machine, grain drying, etc., and can solve the problems of small quantity, high labor cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

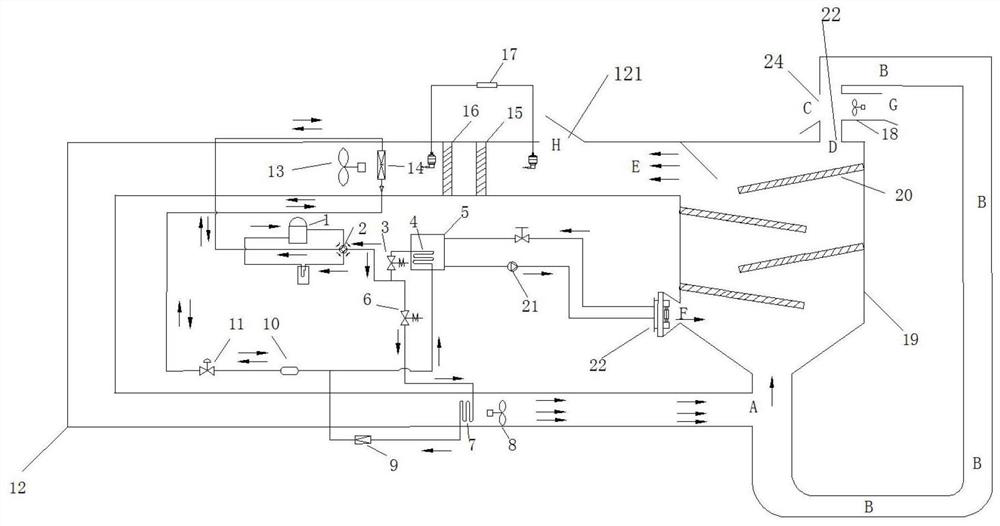

[0039] see figure 1 As shown, a heat recovery closed cycle rice drying system includes a drying room air system and a dryer fluorine system. The drying room air system includes a drying room 19 and an air duct 12. The drying room 19 A conveyor belt 20 is provided inside, and the top of the drying room 19 is provided with a D opening 22, and the upper end of the D opening 22 is connected with a dust removal channel, and the dust removal channel is provided with a G port and a C dust outlet 24. There is a dust removal fan 18 in the mouth, and the dust removal fan 18 and the dust outlet C24 are relatively arranged; the two ends of the air duct 12 are connected with the upper and lower ends of the drying room 19 to form a gas flow circuit; the air duct 12 The interior is provided with an evaporator 14, a blower 13, a second condenser 7, and a centrifugal fan 8 in sequence along the direction of gas flow; the fluorine system of the dryer also includes a compressor 1 and a four-way ...

Embodiment 2

[0050] The difference from Embodiment 1 is that another loop is drawn from the pipeline between the four-way valve 2 and the second solenoid valve 6, and the loop is sequentially provided with a first solenoid valve 3, a first condenser 4, and an expansion valve. 10. Evaporator 14, four-way valve 2; the first condenser 4 is placed in the water tank 5, and the water tank 5 forms a circuit through the water pump 21, the pipeline and the fan coil unit 22, and the fan coil unit 22 is placed in the In drying room 19 sidewalls.

[0051] Further, the side wall below the drying room 19 is provided with an F port, and a fan coil unit 22 is installed in the F port.

[0052] The circuit between the water pump 21 and the fan coil unit 22 is also provided with a control valve.

[0053] The condenser 4 is placed in the water tank 5 .

[0054] The hot water recovered from the water tank 5 can be used as domestic hot water. After the last drying, the recovered heat can be used as domestic h...

Embodiment 3

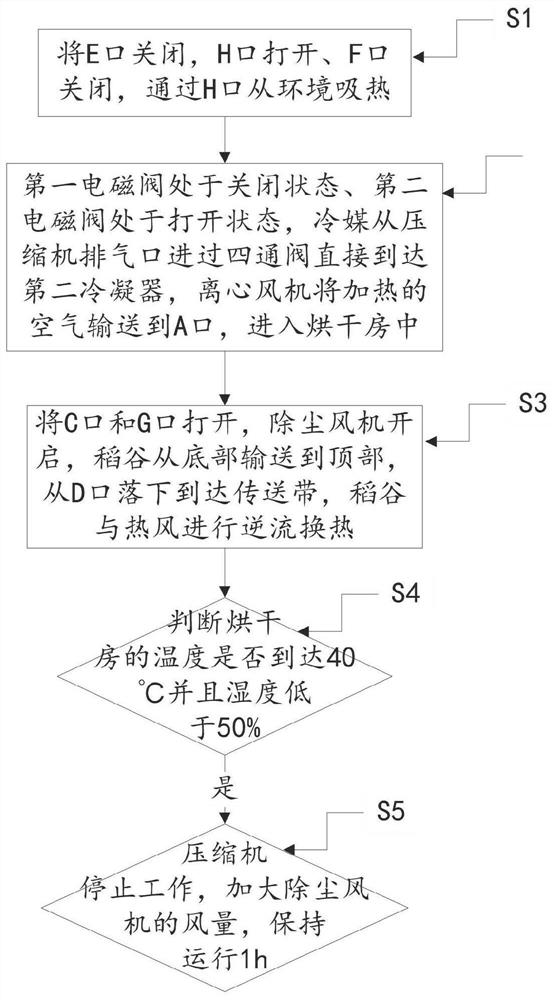

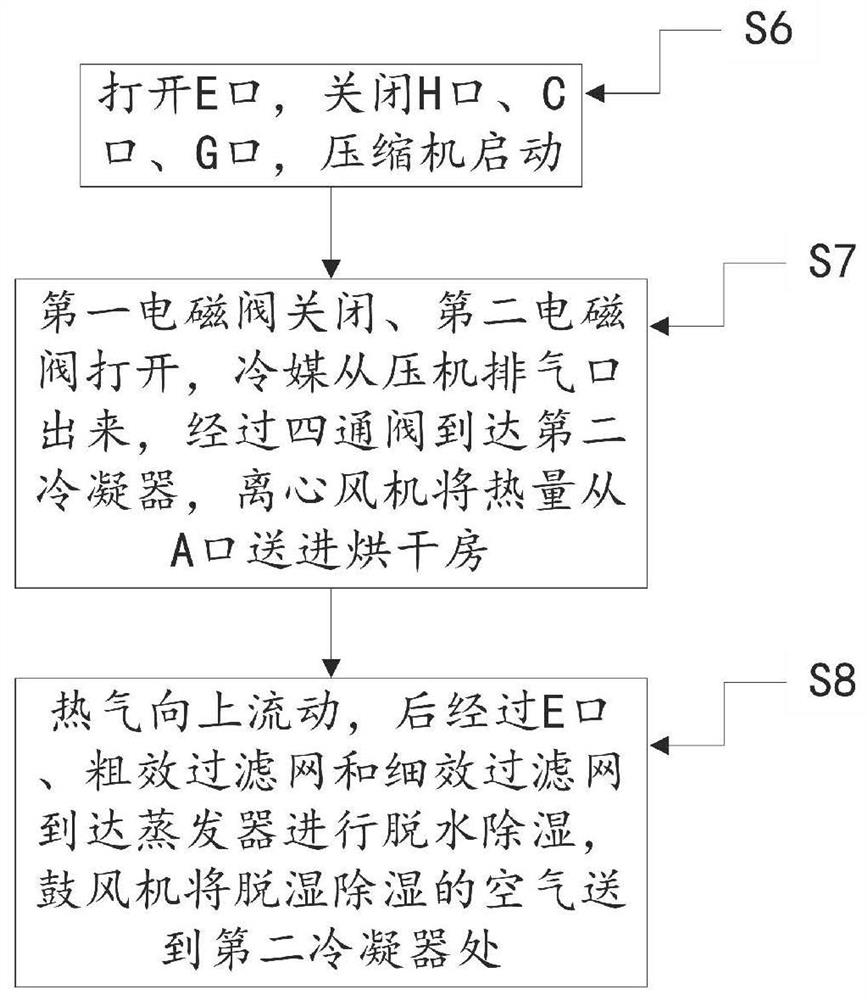

[0058] A heat recovery closed cycle rice drying method, using the heat recovery closed cycle rice drying system described in the above embodiment 1, dust removal is carried out during the initial drying, and the dust removal method includes the following steps:

[0059] S1: Close the E port, open the H port, close the F port, and the fluorine system of the dryer absorbs heat from the environment through the H port;

[0060] S2: The first solenoid valve is in the closed state and the second solenoid valve is in the open state. The refrigerant enters the second condenser through the four-way valve from the exhaust port of the compressor. In the drying room.

[0061] S3: Open the C window and G window, turn on the dust removal fan, the rice is transported from the bottom to the top, and falls from the D port to the conveyor belt. The rice and the hot air perform countercurrent heat exchange, so that the heat exchange effect is better.

[0062] S4: Judging whether the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com