Sound field test analysis method and system based on machine vision and holographic method

A test analysis and machine vision technology, applied in radio wave measurement systems, instruments, measurement devices, etc., can solve the problems of limited application and difficult to obtain the local shape of the sound source surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

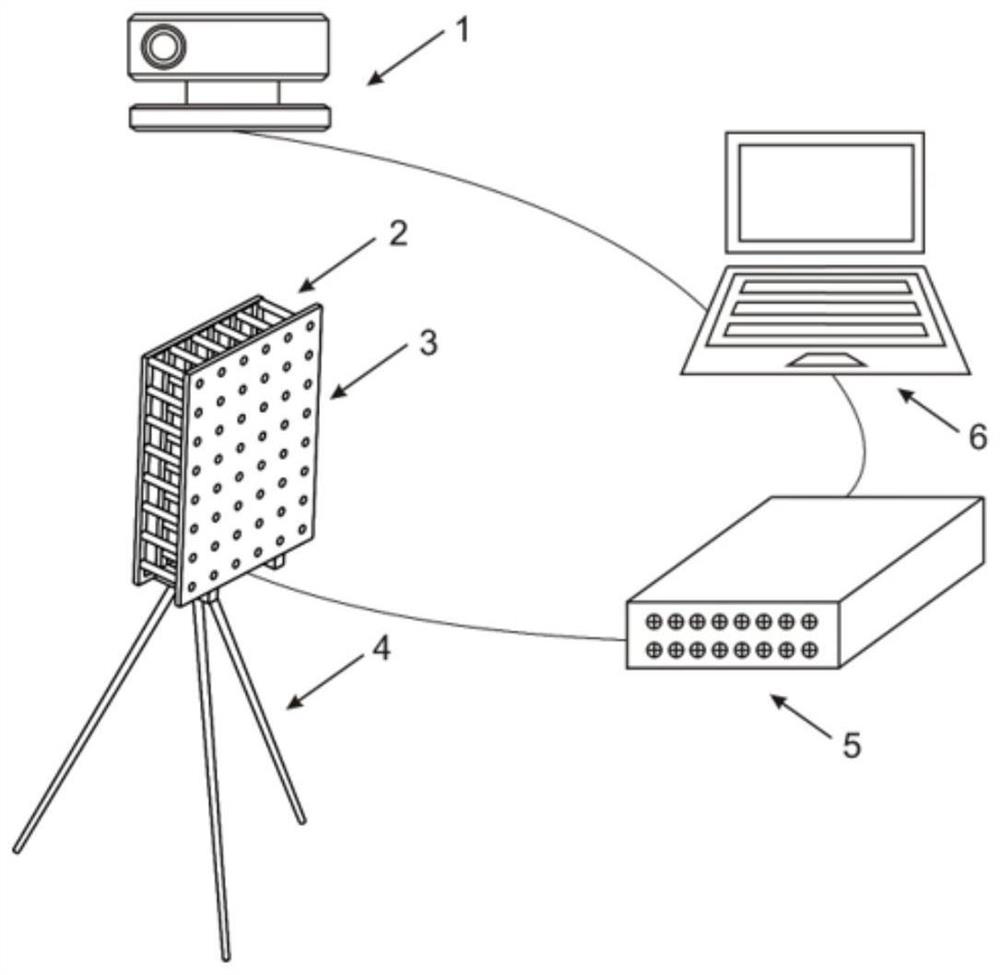

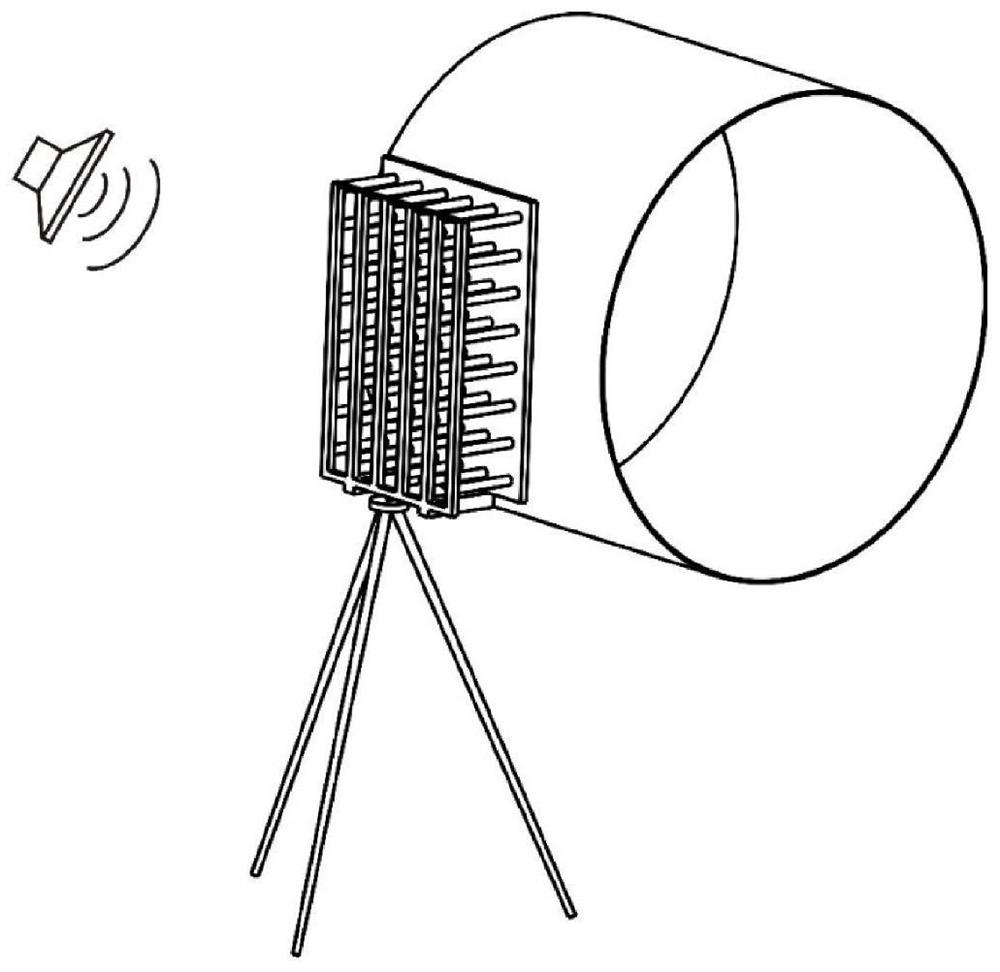

[0025] like figure 1 and figure 2 As shown, this embodiment relates to a sound field test and analysis system based on machine vision methods and holographic methods in a noisy environment, including: camera 1, microphone array 2, rigid acoustic shield 3, base 4, data acquisition module 5 and The camera 1 is directly connected to the sound source reconstruction module 6 .

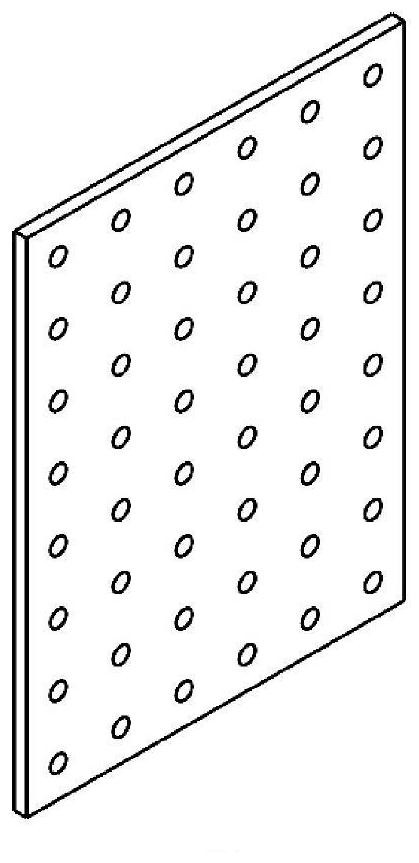

[0026] The microphone array 2 includes a plurality of microphones, the rigid acoustic shielding cover 3 is a plane, and a plurality of openings are discretely arranged on the plane, the number of the openings is consistent with the number of the microphones, and each opening corresponds to each microphone , the microphone is embedded in the corresponding opening of the rigid acoustic shield 3, and the microphone is arranged flush with the inner surface of the rigid acoustic shield 3 to ensure that the normal vibration velocity of the sound pressure collection point is zero.

[0027] The openings are pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com