High-temperature ceramic plate type array capacitor and preparation method thereof

A technology of high-temperature ceramics and capacitors, which is applied in the field of capacitors and can solve problems such as easy damage, reduced reliability of filters, and weak mechanical shock capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

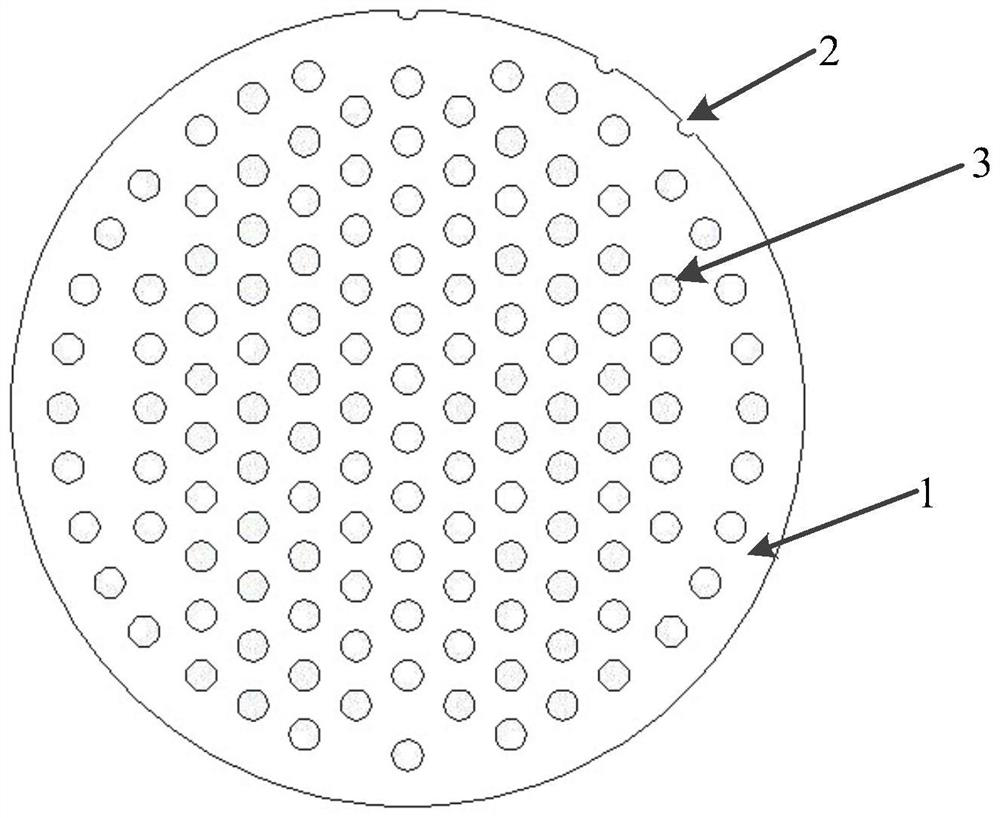

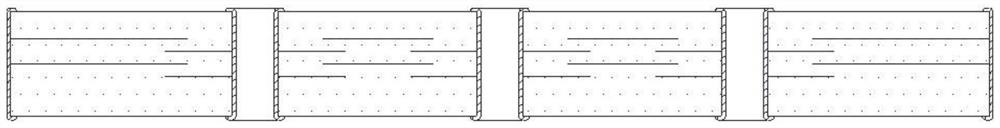

[0030] refer to Figure 1-3 , this embodiment discloses a high-temperature ceramic plate array capacitor, the capacitor body includes: ceramic dielectric 1, internal electrodes and terminal electrodes, the capacitor body is a multi-layer plate structure with a plurality of signal holes, and the internal electrodes include : multiple common ground electrodes and multiple signal electrodes, multiple common ground electrodes and multiple signal electrodes are arranged alternately in the lamination direction of the ceramic medium, and the projection parts of the common ground electrodes and signal electrodes on the lamination plane overlap; each A common ground electrode extends inward from the outer edge of the ceramic dielectric 1 and keeps a distance from the signal hole; each signal pole extends outward from the signal hole and keeps a distance from the outer edge of the capacitor and the signal pole of the adjacent signal hole, Keep a certain distance between adjacent signal ...

Embodiment 2

[0033] This embodiment discloses a method for preparing a high-temperature ceramic plate array capacitor, the method is as follows:

[0034] S1, preparing a green body by wet printing;

[0035] S2. Machining the green body so that the shape of the green body is the same as that of the plate array capacitor and has a certain ratio to the size of the green body;

[0036] S3, debinding and sintering the green body to prepare a ceramic medium 1;

[0037] S4. Prepare the common ground electrode terminal 2, the signal electrode terminal 3, and the surface coating layer on the ceramic medium 1 to complete the preparation of the high-temperature ceramic plate array capacitor.

[0038] The method for preparing the green body by wet printing in step S1 is: preparing a ceramic medium slurry, which is a slurry made by mixing ceramic powder and an organic binder. The organic binder is dissolved in an organic polymer Uniform viscous liquid obtained in an organic solvent; the organic polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com