A kind of double-sided thick film electroplating copper heat dissipation structure manufacturing method

A technology of heat dissipation structure and manufacturing method, which is applied in the direction of circuits, electrical components, and electrical solid devices, and can solve problems such as difficult and complicated operation processes, achieve low cost, solve excessive stress, increase mass production and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A method for manufacturing a double-sided thick-film electroplating copper heat dissipation structure, comprising the following steps:

[0080] S1: Surface treatment on the wafer

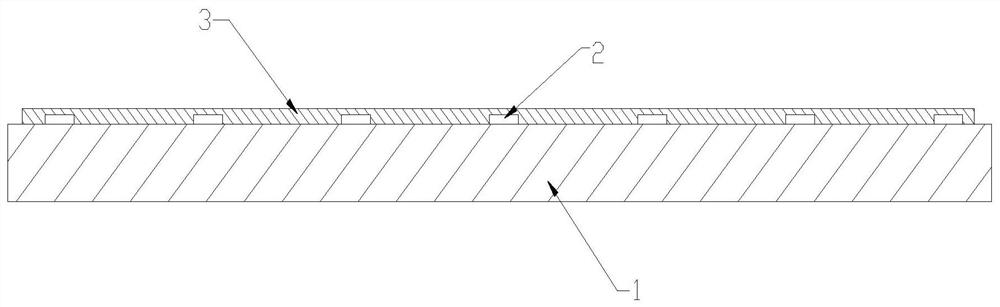

[0081] Perform ion implantation and yellow light process on the upper surface of wafer 1, and make metal contacts 2, such as figure 1 As shown, the thickness of wafer 1 is 700um;

[0082] S2: Depositing thin films

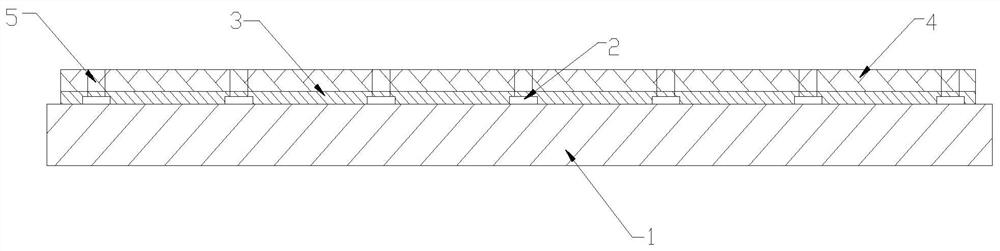

[0083] Surface deposition of SiO on wafer 1 using PEVCD 2 and Si 3 N 4 Film 3, such as figure 2 As shown, the film thickness is 0.5um;

[0084] S3: One polyimide thick film coating

[0085] In SiO 2 and Si 3 N 4 A layer of polyimide thick film 4 is coated on the film 3, and a metal contact window 5 with an area smaller than the area of the metal contact 2 is opened on the metal contact 2 by Mask exposure, such as image 3 As shown, the thickness of the polyimide thick film 4 is 10um, and the polyimide thick film 4 is baked and cured after development;

[0086] S4: E...

Embodiment 2

[0117] A method for manufacturing a double-sided thick-film electroplating copper heat dissipation structure, comprising the following steps:

[0118] S1: Surface treatment on the wafer

[0119] Perform ion implantation and yellow light process on the upper surface of wafer 1, and make metal contacts 2, such as figure 1 As shown, the thickness of wafer 1 is 700um;

[0120] S2: Depositing thin films

[0121] Surface deposition of SiO on wafer 1 using PEVCD 2 and Si 3 N 4 Film 3, such as figure 2 As shown, the film thickness is 1.5um;

[0122] S3: one polyimide thick film coating

[0123] In SiO 2 and Si 3 N 4 A layer of polyimide thick film 4 is coated on the film 3, and a metal contact window 5 with an area smaller than the area of the metal contact 2 is opened on the metal contact 2 by Mask exposure, such as image 3 As shown, the thickness of the polyimide thick film 4 is 15um, and the polyimide thick film 4 is baked and cured after development;

[0124] S4: E...

Embodiment 3

[0155] A method for manufacturing a double-sided thick-film electroplating copper heat dissipation structure, comprising the following steps:

[0156] S1: Surface treatment on the wafer

[0157] Perform ion implantation and yellow light process on the upper surface of wafer 1, and make metal contacts 2, such as figure 1 As shown, the thickness of wafer 1 is 700um;

[0158] S2: Depositing thin films

[0159] Surface deposition of SiO on wafer 1 using PEVCD 2 and Si 3 N 4 Film 3, such as figure 2 Shown, where the film thickness is 1.0um;

[0160] S3: One polyimide thick film coating

[0161] In SiO 2 and Si 3 N 4 A layer of polyimide thick film 4 is coated on the film 3, and a metal contact window 5 with an area smaller than the area of the metal contact 2 is opened on the metal contact 2 by Mask exposure, such as image 3 As shown, the thickness of the polyimide thick film 4 is 20um, and the polyimide thick film 4 is baked and cured after development;

[0162] S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com