A kind of lithium battery negative electrode binder and its preparation method and application

A technology for the preparation of binders and lithium batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced negative active material content, large difference in the impedance of negative electrode sheets, and easy cracking of negative electrode sheets. Processing is not easy to break, the effect of excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

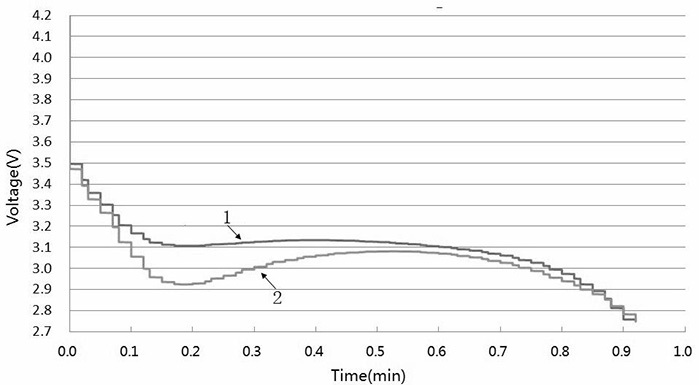

[0030] This embodiment provides a negative electrode binder for lithium batteries and its preparation method and application. The advantages of the styrene-butadiene rubber binder, using the binder to prepare a negative electrode sheet with small impedance and excellent processability, and using the negative electrode sheet to manufacture lithium batteries, to solve the existing technical problems: when the lithium battery is discharged at a large rate, the surface of the battery The temperature rises sharply, which is manifested as an undercut in the initial stage of the discharge curve, which has a great potential safety hazard.

[0031] Calculated in parts by mass, the raw materials for the preparation of the binder in this embodiment include the following components: 41.0 parts of polyacrylonitrile emulsion, 10.0 parts of butadiene and 10.0 parts of styrene.

[0032] The preparation method of the lithium battery negative electrode binder specifically includes the following...

Embodiment 2

[0052] This example provides a lithium battery negative electrode binder and its preparation method and application. Compared with Example 1, the binder in this example has adjusted the composition and proportion of the raw materials for preparation, as well as the process of the preparation method parameter. Calculated in parts by mass, the raw materials for the preparation of the binder in this embodiment include the following components: 51.0 parts of polyacrylonitrile derivative emulsion, 20.0 parts of butadiene derivative and 20.0 parts of styrene.

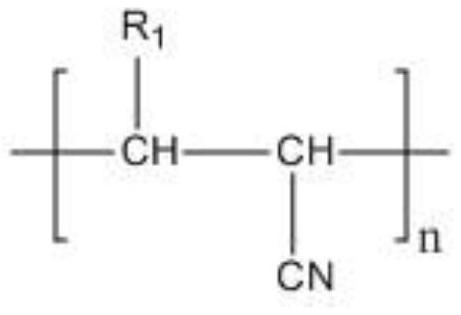

[0053] The structural formula of polyacrylonitrile derivatives is as follows:

[0054]

[0055] Wherein, R1 is an amino group.

[0056] The structural formula of butadiene derivatives is as follows:

[0057]

[0058] Wherein, R2 is amino.

[0059] The preparation method of the lithium battery negative electrode binder specifically includes the following steps:

[0060] S1. Prepare each component according to the raw...

Embodiment 3

[0068] This example provides a lithium battery negative electrode binder and its preparation method and application. Compared with Example 1, the binder in this example has adjusted the composition and proportion of the raw materials for preparation, as well as the process of the preparation method parameter. Calculated in parts by mass, the raw materials for the preparation of the binder in this embodiment include the following components: 44.0 parts of polyacrylonitrile derivative emulsion, 13.5 parts of butadiene derivative and 13.5 parts of α-methylstyrene.

[0069] The structural formula of polyacrylonitrile derivatives is as follows:

[0070]

[0071] Wherein, R1 is an ester group.

[0072] The structural formula of butadiene derivatives is as follows:

[0073]

[0074] Wherein, R2 is an ester group.

[0075] The preparation method of the lithium battery negative electrode binder specifically includes the following steps:

[0076] S1. Prepare each component acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com