Seed and hull separation machine

A separator and seed shell technology, applied in the field of agricultural machinery, can solve the problems of poor separation effect and low separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

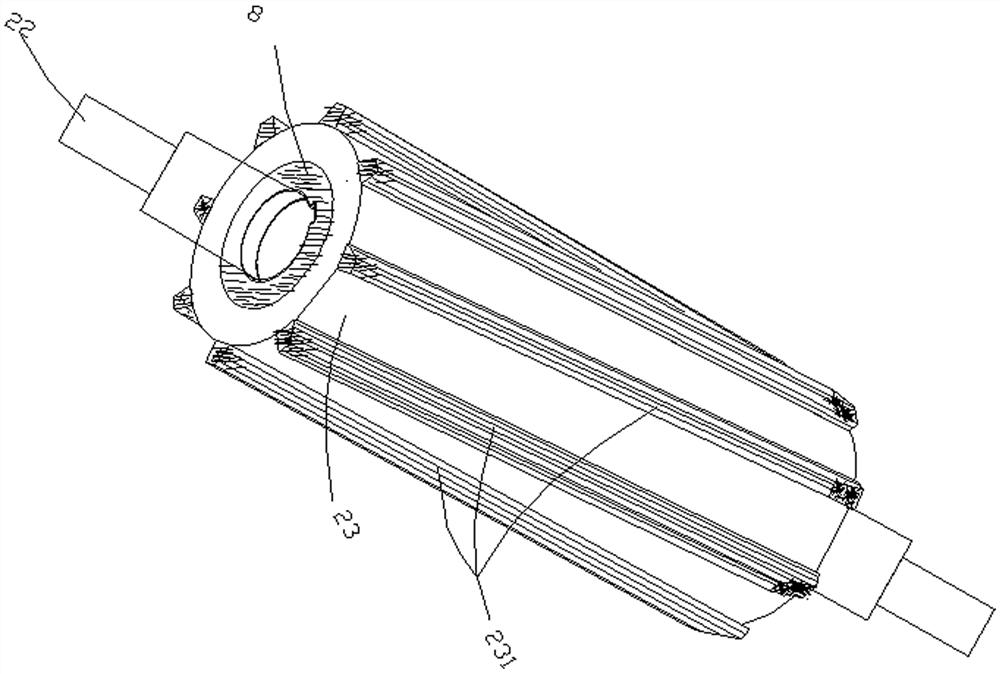

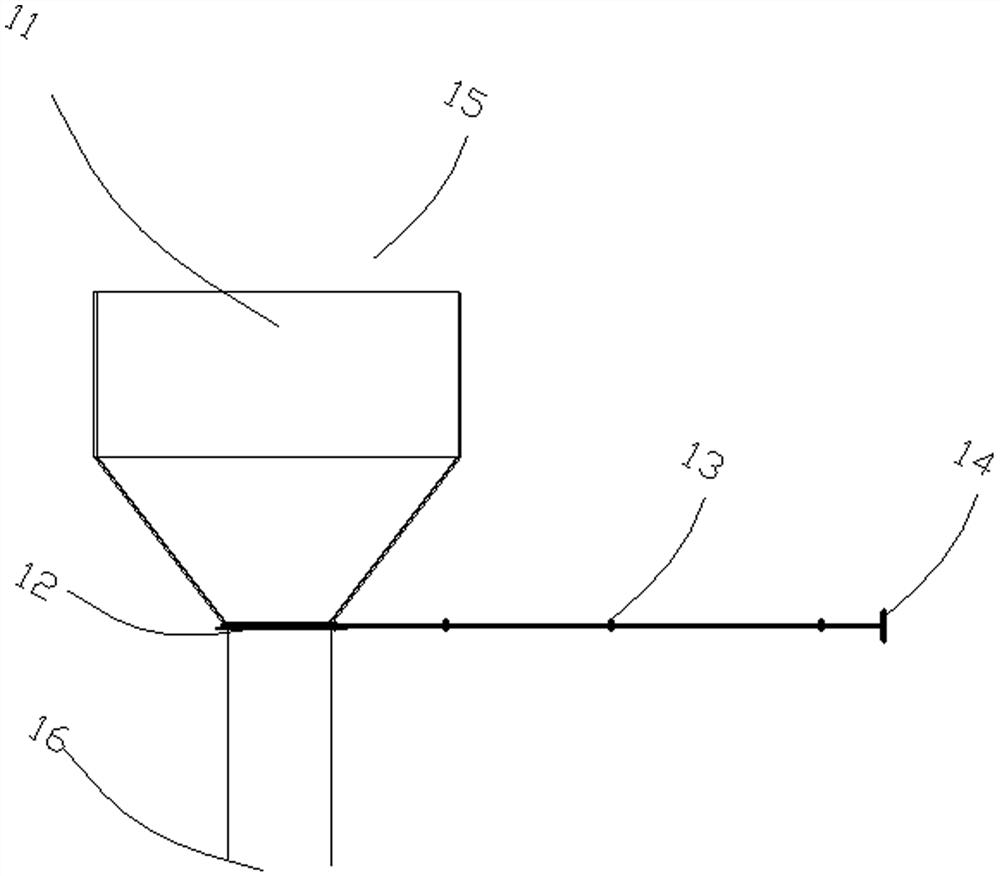

[0026] Such as figure 1 As shown, the present embodiment provides a seed husk separator, including a frame 4, on which a feeding device 1, a rotating device 2 connected to the feeding device 1, and a driving device that provides power for the rotating device 2 are provided on the frame 4 3;

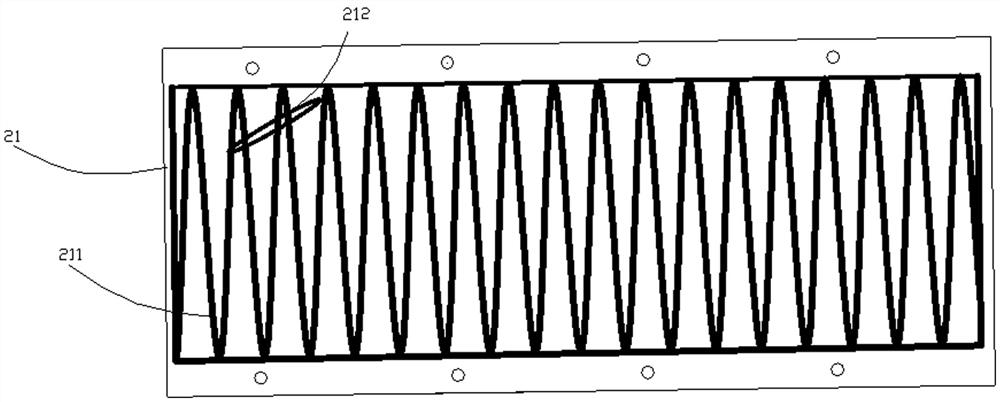

[0027] The rotating device 2 includes a shell screen drum 21 fixed on the frame 4 and a rotating shaft 22 rotating in the shell screen drum 21. The rotating shaft 22 is driven by the driving device 3, and the surface of the shell screen drum 21 is arranged in a spiral shape. The smooth slit 211 is provided with a feed port to connect with the feed device 1;

[0028] A stirring mechanism is provided on the rotating shaft 22 , and the stirring mechanism includes a roller 23 fixed on the rotating shaft 22 and a brush strip 231 arranged on the surface of the roller 23 .

[0029] Such as figure 2 As shown, the shelling screen cylinder 21 can be segmentally independent and connected to each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com