Manufacturing method for 3D printing workpiece with high interfacial heat conductivity

A technology of thermal conductivity and 3D printing, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as non-continuous production, prone to defects in plate products, and inability to obtain parts with high thermal conductivity between surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

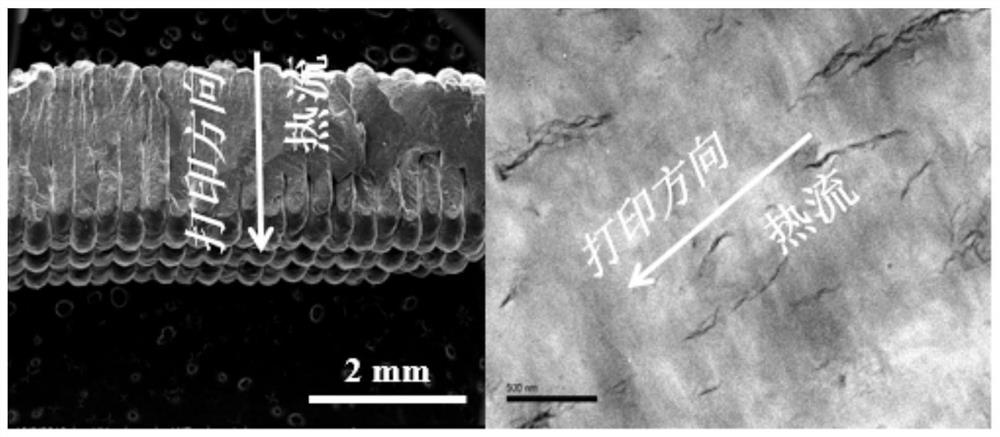

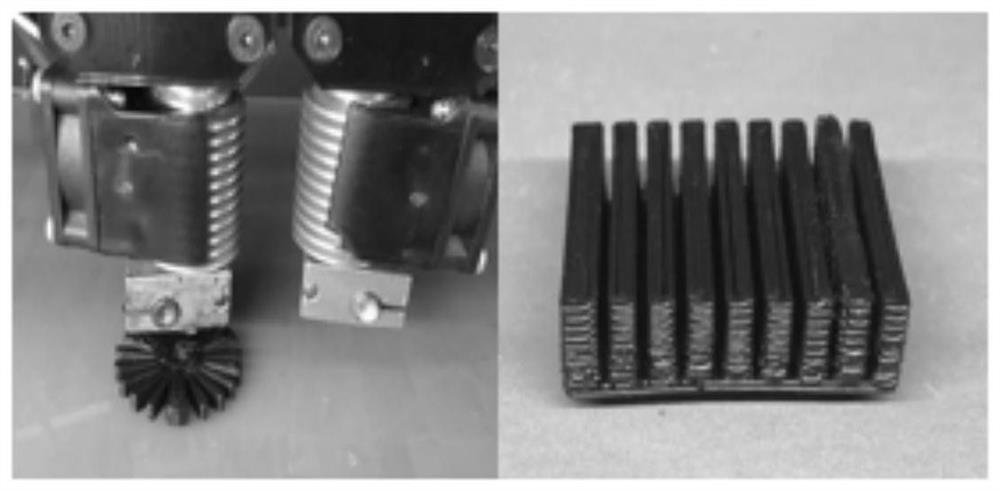

[0052] This embodiment adopts a method for preparing a 3D printed part with high thermal conductivity between surfaces, which includes the following steps in parts by weight:

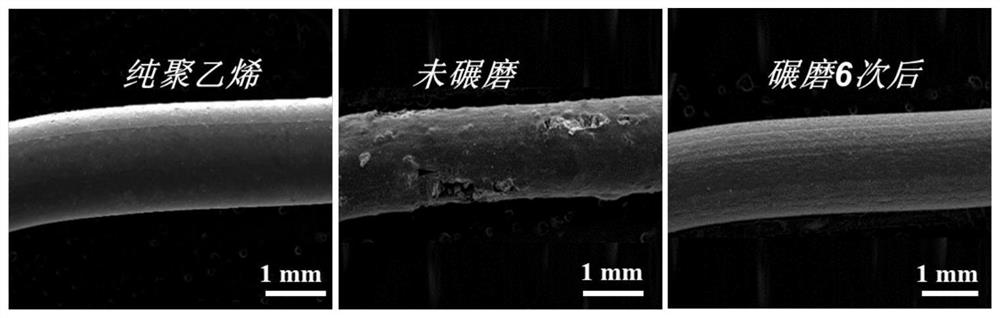

[0053] (1) After mixing 100 parts of low-density polyethylene and 20 parts of graphene nanosheets, add them to a disc-shaped mechanochemical reactor for grinding and pulverization. After the grinding is completed, collect carbon-based fillers and evenly disperse them in the polymer matrix. Composite material powder; among them, the process parameters of the disc-shaped mechanochemical reactor are: the grinding pressure is 30MPa, the temperature of the disc surface is controlled by feeding a constant temperature circulating liquid medium with a temperature of 35°C, cyclic grinding 6 times, and the disc rotation speed 30r / min;

[0054] (2) Extrude the composite material powder obtained in step (1) to obtain a filament for 3D printing. The extrusion processing parameters are: extrusion temperature 170°C, ...

Embodiment 2

[0064] This embodiment adopts a method for preparing a 3D printed part with high thermal conductivity between surfaces, which includes the following steps in parts by weight:

[0065] (1) After mixing 100 parts of low-density polyethylene and 20 parts of carbon nanotubes, they are added to a disc-shaped mechanochemical reactor for grinding and pulverization. After the grinding is completed, carbon-based fillers are collected and evenly dispersed in the polymer matrix. Material powder; among them, the process parameters of the disc-shaped mechanochemical reactor are as follows: the grinding pressure is 25MPa, the temperature of the disc surface is controlled by feeding a constant temperature circulating liquid medium with a temperature of 35°C, and the grinding cycle is 6 times, and the rotational speed of the disc is 30r / min;

[0066] (2) Extrude the composite material powder obtained in step (1) to obtain a filament for 3D printing. The extrusion processing parameters are: e...

Embodiment 3

[0076] This embodiment adopts a method for preparing a 3D printed part with high thermal conductivity between surfaces, which includes the following steps in parts by weight:

[0077] (1) After mixing 100 parts of low-density polyethylene and 40 parts of graphene nanosheets, add them to a disc-shaped mechanochemical reactor for grinding and pulverization. After the grinding is completed, collect carbon-based fillers and evenly disperse them in the polymer matrix. Composite material powder; Among them, the process parameters of the disc-shaped mechanochemical reactor are: the grinding pressure is 30MPa, the temperature of the disc surface is controlled by feeding a constant temperature circulating liquid medium at a temperature of 40°C, and the grinding cycle is 6 times, and the disc rotation speed is 30r / min;

[0078] (2) Extrude the composite material powder obtained in step (1) to obtain a filament for 3D printing. The extrusion processing parameters are: extrusion temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com