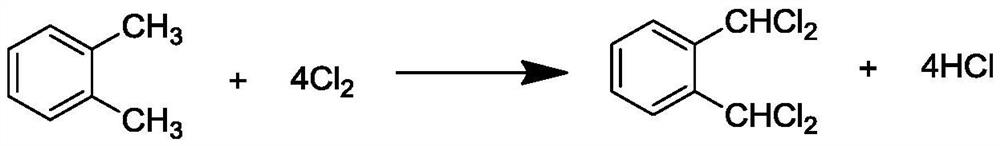

Preparation process of alpha, alpha, alpha ', alpha'-tetrachloro-o-xylene

A preparation process, o-xylene technology, applied in the direction of halocarbon preparation, halocarbon disproportionation separation/purification, organic chemistry, etc., can solve the problems of low product content and difficult disposal of waste liquid, so as to improve product content and benefit maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The system for preparing α, α, α', α'-tetrachloro-o-xylene in this embodiment includes devices such as aeration system, reaction equipment and falling film absorption tower, wherein the reaction equipment includes a reactor (or chlorine reactor), Purification equipment includes crystallization kettles.

[0031] The following are the concrete steps of this embodiment:

[0032] 1. Turn on the replacement nitrogen before feeding, and purge the chlorine tank for 0.5h to replace the air in the tank. After the replacement, pump 1000kg of o-xylene into the chlorine tank, and add pre-separated gas from the sight glass of the chlorine tank. Installed 8kg of phosphorus trichloride, turn on the nitrogen, and blow nitrogen into the kettle system for about 30 minutes, so that o-xylene and phosphorus trichloride can be fully mixed; at the same time, phosphorus trichloride can absorb part of the water. After o-xylene and phosphorus trichloride are evenly mixed, a small amount of mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com