Extraction method for salidroside

A technology of salidroside and extraction method, applied in chemical instruments and methods, mixers with rotary stirring devices, preparation of sugar derivatives, etc., can solve the problem of low extraction rate of salidroside and transfer rate of salidroside lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The extraction method of salidroside comprises the following steps:

[0042] Step 1, cleaning rhodiola rosea rhizomes, drying and crushing to obtain crushed rhodiola rosea;

[0043] Step 2: Add 25 times the total mass of buffer solution to the crushed rhodiola, adjust the pH of the system to 4-5, stir at 35°C for 3 minutes, and add rhodiola to the crushed rhodiola 0.005 times the amount of protease, 0.012 times the amount of pectinase, and 0.008 times the amount of cellulase of the total mass of the ground material, and placed in an ultrasonic device for extraction, after the extraction is completed, the enzyme is inactivated to obtain an enzymatic solution. at 45°C, the extraction time is 100min;

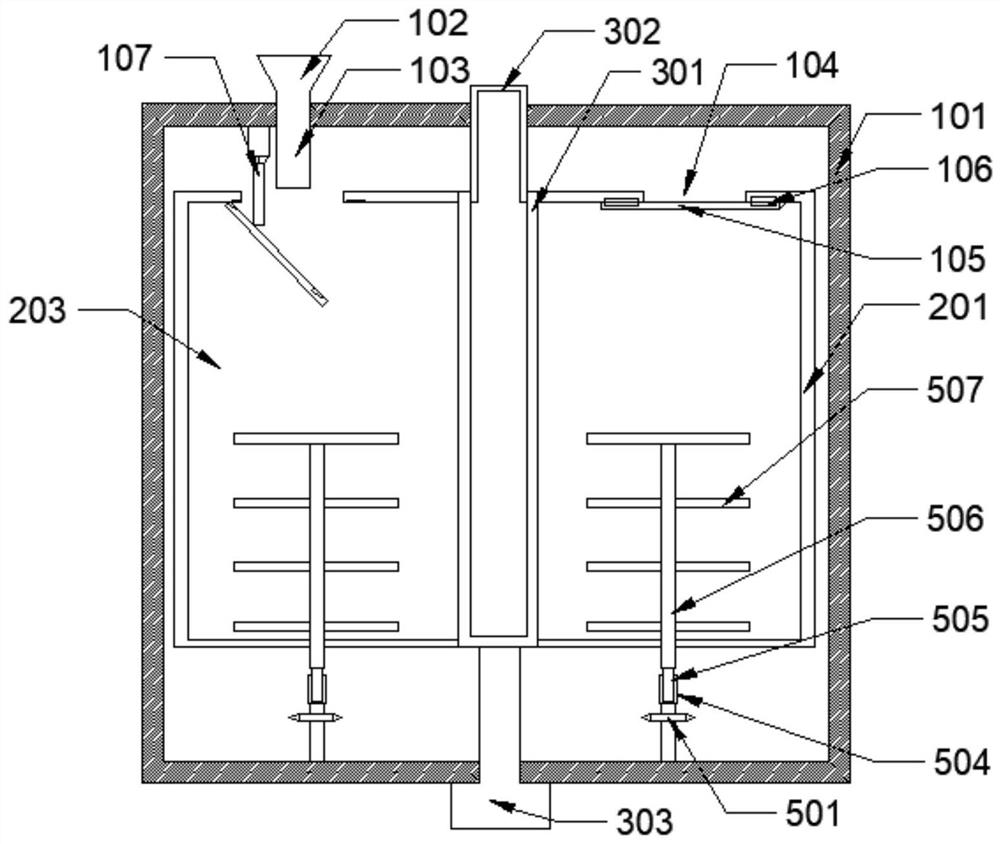

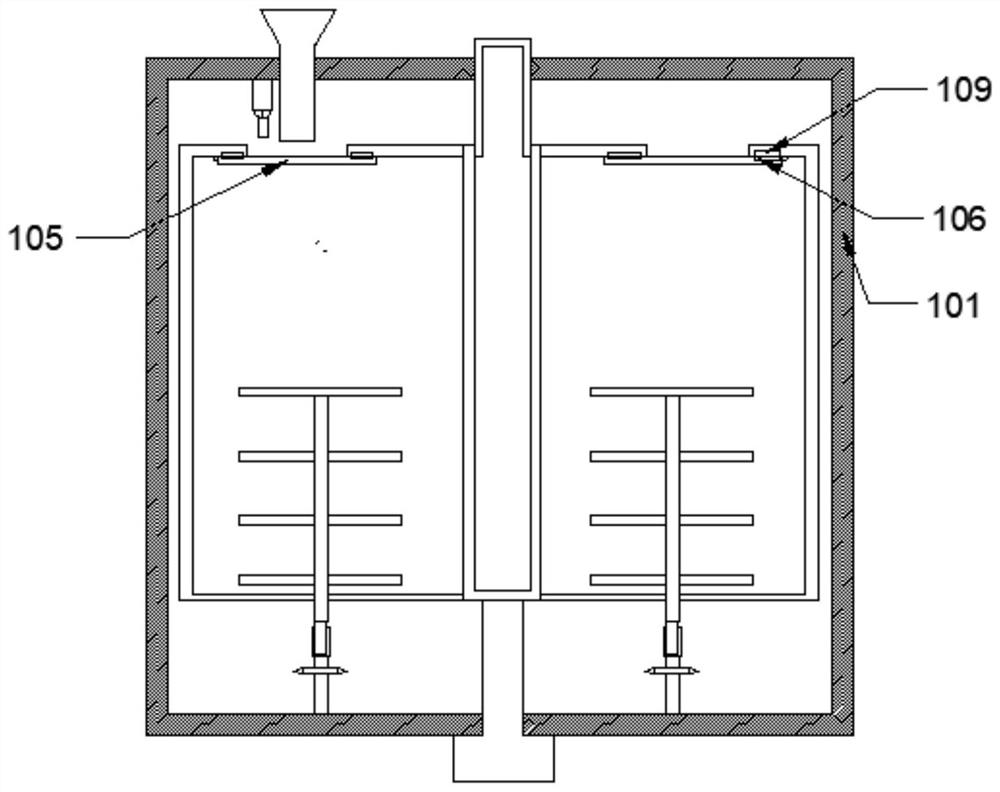

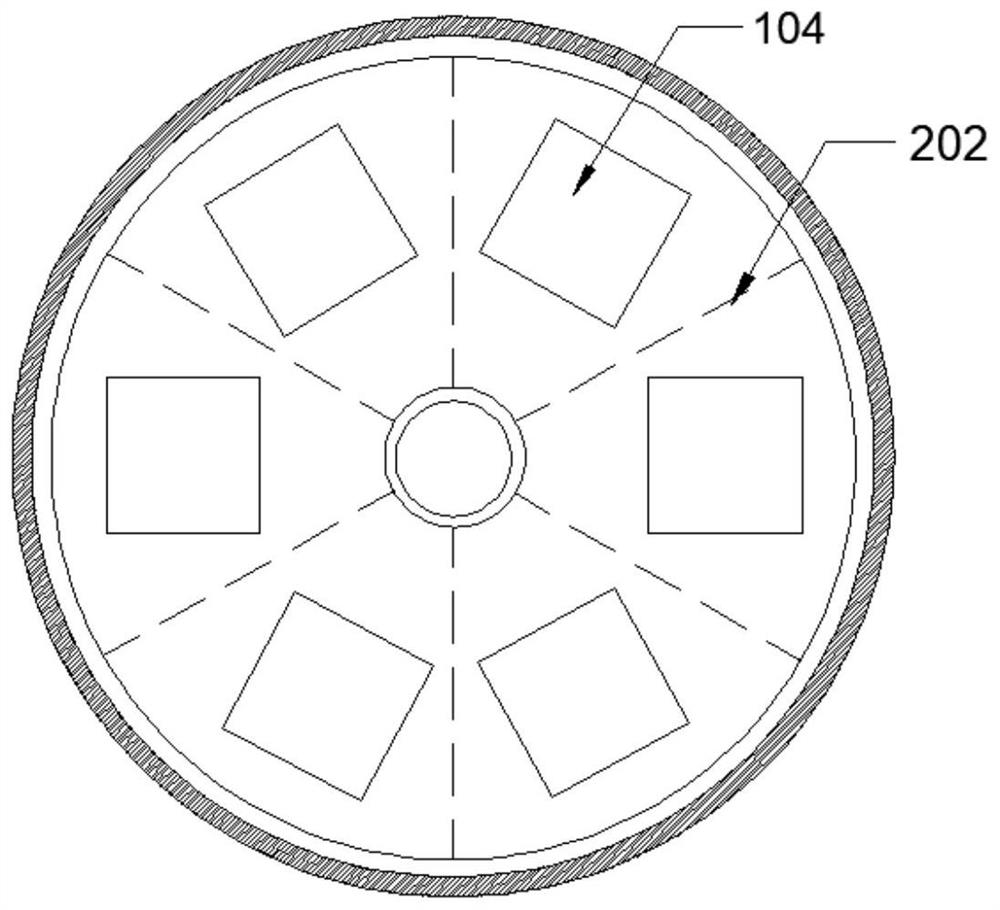

[0044] Step 3. Add the enzymatic hydrolysis liquid into the extraction tank in batches to obtain the crude extract of Rhodiola rosea. The treatment method for each batch of enzymatic hydrolysis liquid is: b1. Add water to the enzymatic hydrolysis liquid and place it at 35°C...

Embodiment 2

[0050] The extraction method of salidroside comprises the following steps:

[0051] Step 1, cleaning rhodiola rosea rhizomes, drying and crushing to obtain crushed rhodiola rosea;

[0052] Step 2: Add 25 times the total mass of buffer solution to the crushed rhodiola, adjust the pH of the system to 4-5, stir at 45°C for 7 minutes, and add rhodiola to the crushed rhodiola 0.005 times the amount of protease, 0.012 times the amount of pectinase, and 0.008 times the amount of cellulase of the total mass of the ground material, and placed in an ultrasonic device for extraction, after the extraction is completed, the enzyme is inactivated to obtain an enzymatic solution. The temperature is 55°C, and the extraction time is 130min;

[0053] Step 3. Add the enzymatic hydrolysis liquid into the extraction tank in batches to obtain the crude extract of Rhodiola rosea. The treatment method for each batch of enzymatic hydrolysis liquid is: b1. Add water to the enzymatic hydrolysis liquid ...

Embodiment 3

[0059] A method for extracting salidroside, comprising the following steps:

[0060] Step 1, cleaning rhodiola rosea rhizomes, drying and crushing to obtain crushed rhodiola rosea;

[0061] Step 2: Add 25 times the total mass of buffer solution to the crushed rhodiola, adjust the pH of the system to 4-5, stir at 40°C for 5 minutes, and add rhodiola to the crushed rhodiola 0.005 times the amount of protease, 0.012 times the amount of pectinase, and 0.008 times the amount of cellulase of the total mass of the ground material, and placed in an ultrasonic device for extraction, after the extraction is completed, the enzyme is inactivated to obtain an enzymatic solution. 50°C, the extraction time is 120min;

[0062] Step 3. Add the enzymatic hydrolysis liquid into the extraction tank in batches to obtain the crude extract of Rhodiola rosea. The treatment method for each batch of enzymatic hydrolysis liquid is: b1. Add water to the enzymatic hydrolysis liquid and place it at 40°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com