High-water-retention polycarboxylate superplasticizer and preparation method thereof

A water-retaining polycarboxylic acid technology, applied in the field of concrete admixtures, can solve problems such as high cost, complicated preparation process, and poor water-retaining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

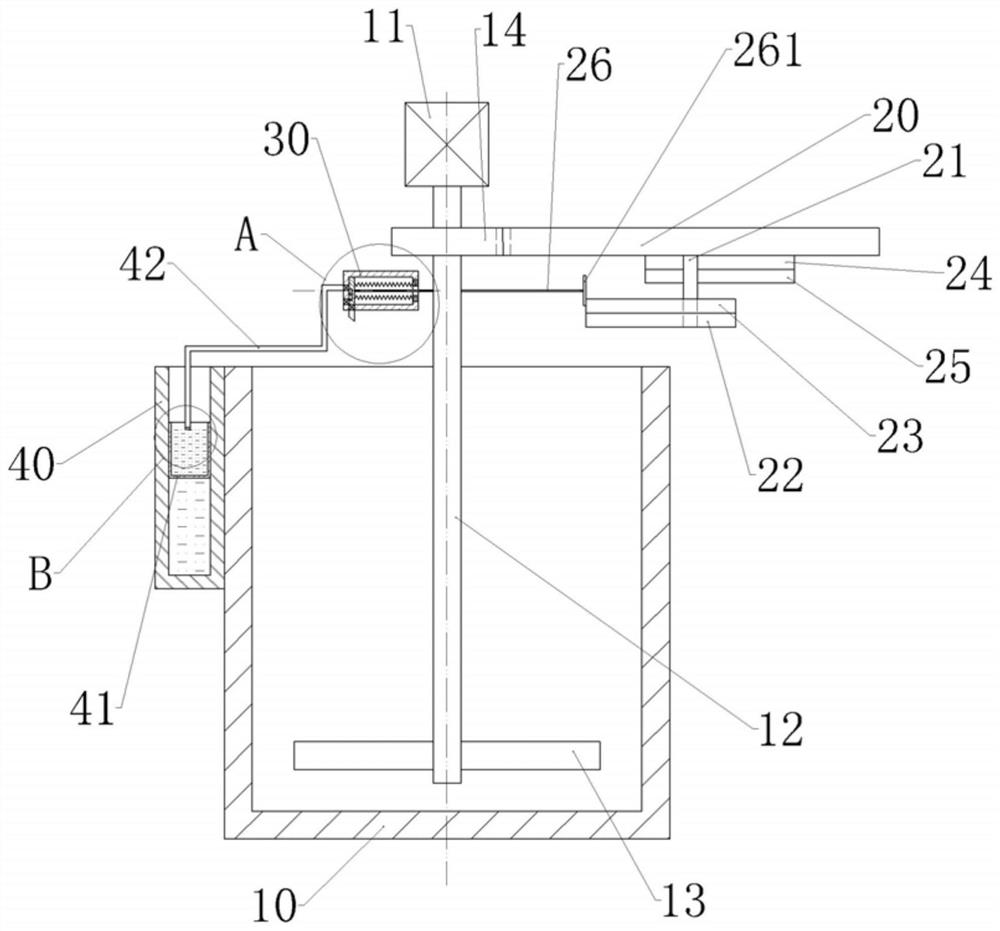

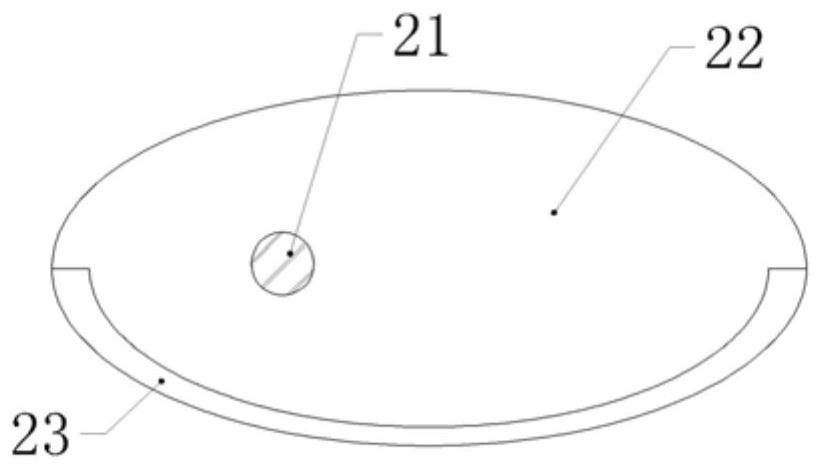

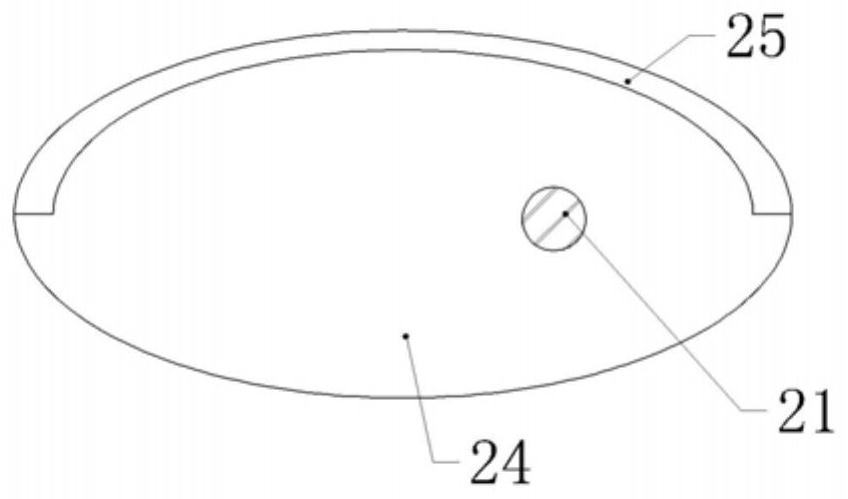

[0047] Embodiment 1 is basically as attached figure 1 - attached Figure 6 Shown:

[0048] (1) 100 parts of maleic anhydride, 750 parts of polyethylene glycol monomethyl ether (Mn=750) and 1 g of p-toluenesulfonic acid were added to a four-necked flask, and reacted for 2 hours at 100° C. At room temperature, polyethylene glycol monomethyl ether maleic anhydride ester is obtained.

[0049] (2) Add 300g of EPEG polyether (Mn=3000) and 240g of deionized water into a four-necked flask, start stirring, and after the polyether monomer is completely dissolved, add the polyethylene glycol monomethyl ether produced in step (1) Ether maleic anhydride 21g and 4g sodium hypophosphite, after stirring for 10 minutes, add 2g hydrogen peroxide; prepare A and B solutions, of which A solution: 25g acrylic acid + 1.2g allyl methacrylate + 30g deionized water; B solution: 0.45 gE51+50g deionized water; when the temperature of the bottom solution is controlled at 15±2°C, the prepared A and B so...

Embodiment 2

[0063] The difference between embodiment 2 and embodiment 1 is:

[0064] (1) 100 parts of maleic anhydride, 750 parts of polyethylene glycol monomethyl ether (Mn=750) and 1 g of p-toluenesulfonic acid were added to a four-necked flask, and reacted for 2 hours at 100° C. At room temperature, polyethylene glycol monomethyl ether maleic anhydride ester is obtained.

[0065] (2) Add 300g of EPEG polyether (Mn=3000) and 240g of deionized water into a four-necked flask, start stirring, and after the polyether monomer is completely dissolved, add the polyethylene glycol monomethyl ether produced in step (1) Add 21g of ether maleic anhydride ester, stir for 10min and add 2.6g of hydrogen peroxide; prepare A and B solutions, wherein A solution: 25g acrylic acid + 1.2g allyl methacrylate + 30g deionized water; B solution: 0.9g VC + 2.3g Mercaptopropionic acid + deionized water; when the temperature of the solution at the bottom of the kettle is controlled at 20±2°C, the prepared A and ...

Embodiment 3

[0068] The difference between embodiment 3 and embodiment 1 is:

[0069] (1) 98 parts of maleic anhydride, 600 parts of polyethylene glycol monomethyl ether (Mn=600) and 1.47 g of p-toluenesulfonic acid were added to a four-necked flask, and reacted for 2 hours at 100° C. To room temperature, polyethylene glycol monomethyl ether maleic anhydride ester is obtained.

[0070] (2) Add 300g of EPEG polyether (Mn=3000) and 220g of deionized water into a four-neck flask, start stirring, and after the polyether monomer is completely dissolved, add the polyethylene glycol monomethyl ether produced in step (1) 19g of ether maleic anhydride ester and 0.8g of mercaptopropionic acid, after stirring for 10min, add 2.4g of hydrogen peroxide; prepare A and B solutions, wherein A solution: 25g acrylic acid + 1.2g allyl methacrylate + 30g deionized water; B solution : 0.8gVC + 0.8g mercaptopropionic acid + deionized water; when the temperature of the solution at the bottom of the kettle is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com