Self-repairing transparent polyurethane composite material with electrical conductivity and thermal reversibility and preparation method thereof

A composite material, reversible technology, applied in the direction of coating, can solve the problem that there is no self-healing polyurethane composite material research or report.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.7g MDI into 5mL DMF solvent, stir in a 40°C water bath for 5min, then add 3.5gPPG2000 dropwise, raise the temperature to 60°C and continue stirring for 10min. After cooling down to 0°C, add 0.2mL Fam dropwise, react in an ice-water bath for 20 minutes, return to room temperature, use furfurylamine to block the isocyanate, and continue the reaction for 20 minutes to form a polyurethane prepolymer (MPF) with furan ends;

[0039] Add 1g of BMI to MPF, raise the temperature to 50°C again, stir and react for 10h, then pour the synthetic product upside down into a polytetrafluoroethylene template, and process it in a vacuum oven at 50°C for 10h to obtain the product PU-DA .

Embodiment 2

[0041] Add 1g of MDI into 10mL of DMF solvent, stir in a water bath at 50°C for 10min, then add 4g of PPG2000 dropwise, raise the temperature to 70°C and continue stirring for 15min. After cooling down to 0°C, add 0.3mL Fam dropwise, react in an ice-water bath for 30 minutes, return to room temperature, use furfurylamine to block the isocyanate, and continue the reaction for 30 minutes to form a polyurethane prepolymer (MPF) with furan ends;

[0042] Add 2g of BMI to MPF, raise the temperature to 60°C again, stir and react for 12 hours, apply the diluted nano-silver wires evenly on the surface of the template by drop coating method, pour the synthesized product upside down into the polytetrafluoroethylene template, and cast it at 60°C After drying under vacuum for 12h, it is PU-DA / Ag.

[0043] Performance analysis was performed on the intermediate products in the preparation process in the above examples and the final product of the present invention.

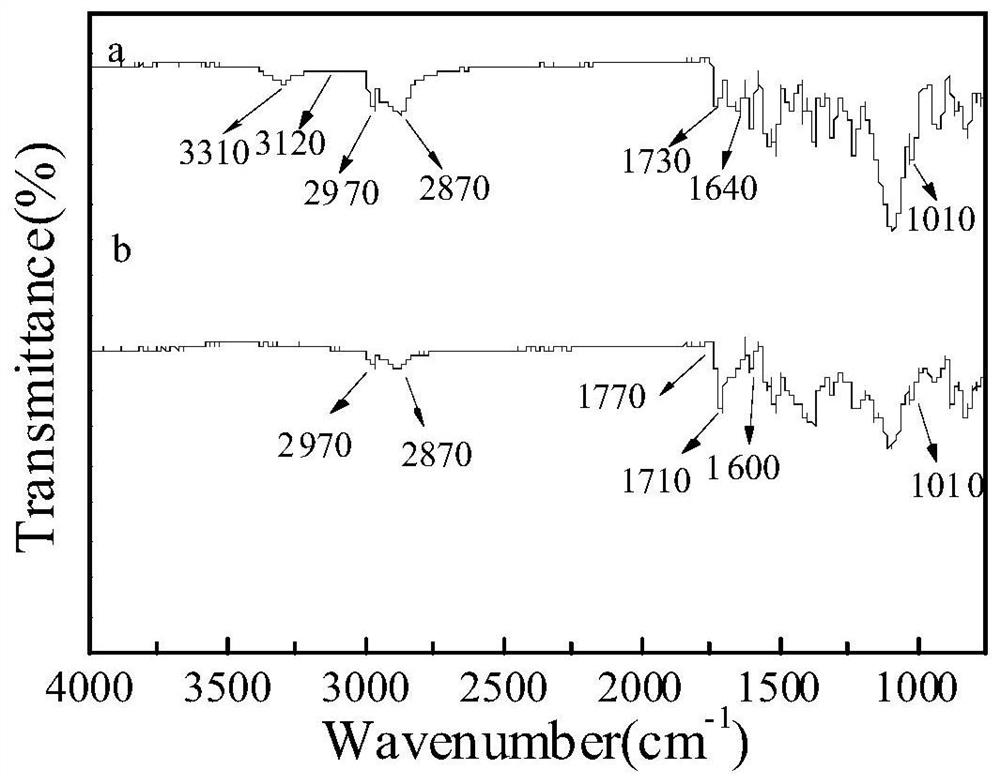

[0044] figure 1 FTIR ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com