Bacterium and enzyme mixed preparation containing Stenotrophomonas pavanii and application of bacterium and enzyme mixed preparation

A technology of Stenotrophomonas and maltophilia, applied in the field of microbiology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

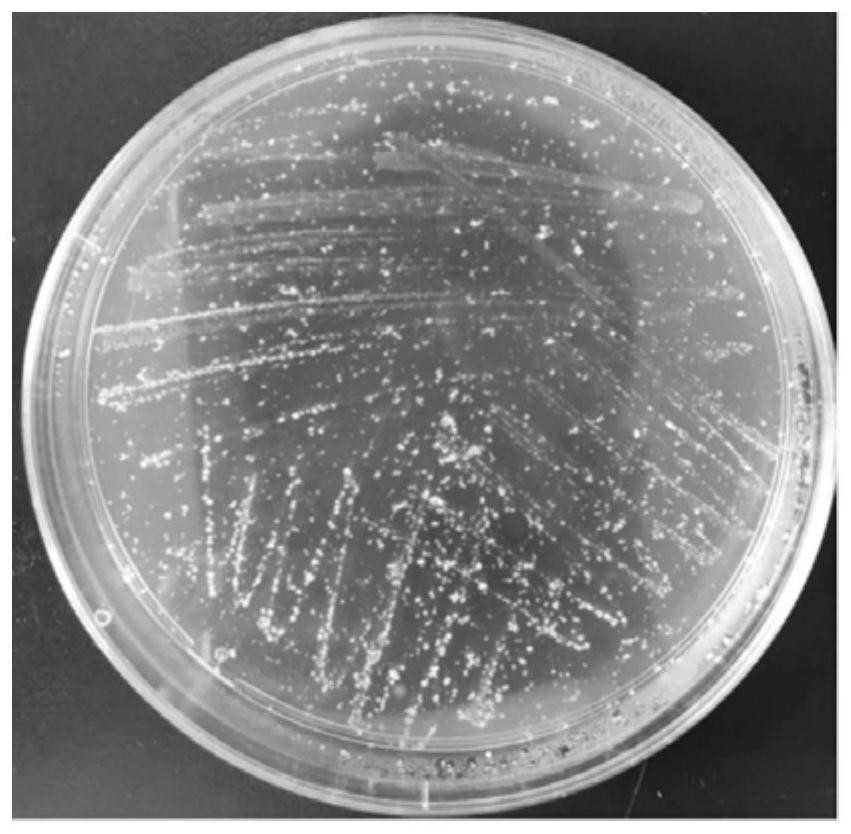

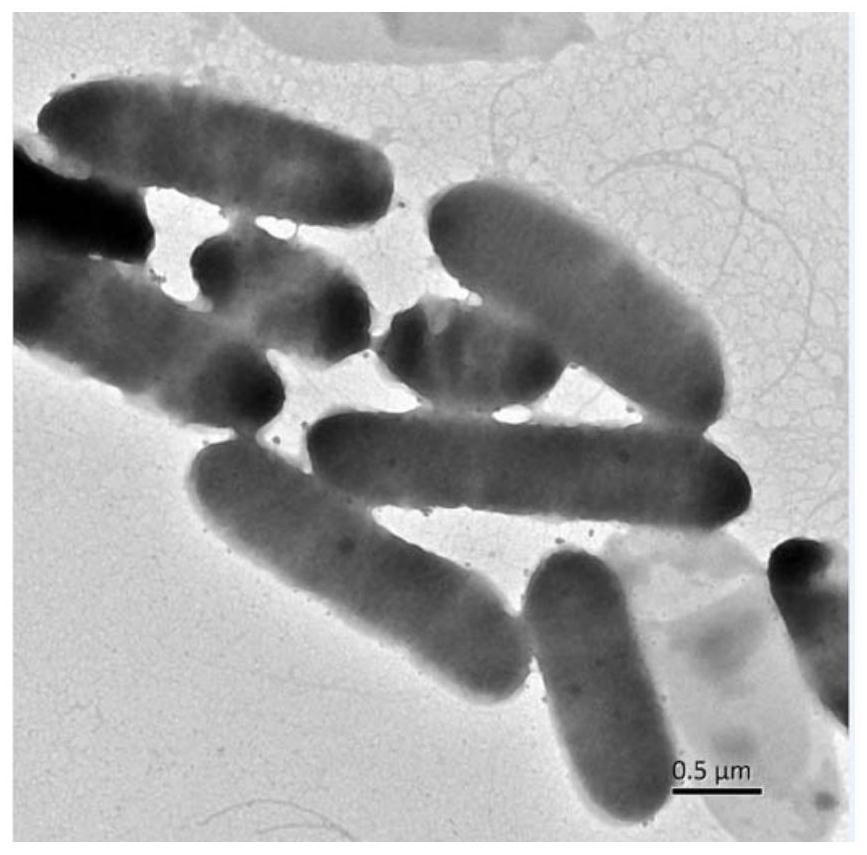

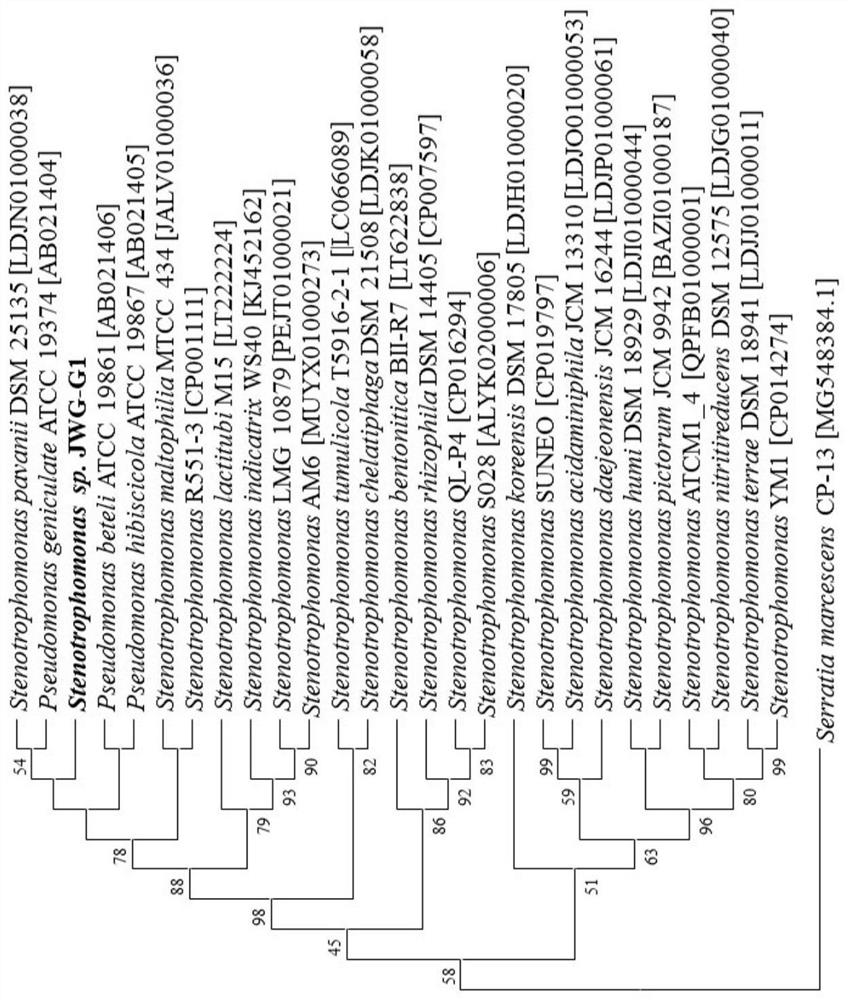

[0060] Example 1: Screening and identification of Stenotrophomonas pavanii

[0061] 1. Screening of Stenotrophomonas pavanii

[0062] Specific steps are as follows:

[0063] 1. Ordinary screening

[0064] Taking the soil from the Taohuashan landfill in Wuxi City as a sample, take 1g of soil and add 9mL of normal saline, shake and enrich for 30min at 35°C and 180rpm; then take 1mL of the supernatant and dilute to 10 -4 、10 -5 、10 -6 , respectively take 200μL and dilute to 10 -4 、10 -5 、10 -6 The diluted solution was evenly spread on the inorganic salt solid medium containing 2g / L polyethylene terephthalate (PET), and placed in a 35°C incubator for constant temperature cultivation until colonies grew; the experimental results showed that after many Daily culture, no bacterial colonies appeared on the separation plate, this method can not effectively isolate the bacterial strain with the ability to degrade polyethylene terephthalate (PET).

[0065] 2. "PET induction cultu...

Embodiment 2

[0079] Embodiment 2: the preparation of bacterial enzyme mixed preparation

[0080] Specific steps are as follows:

[0081] (1) Activated strains: Spread Stenotrophomonas maltophilia JWG-G1 on an LB solid medium plate and culture at 37°C and 150rpm for 1 day to obtain a single colony;

[0082] (2) Preparation of seed solution: scrape the single colony obtained in step (1) and inoculate it into a glass test tube of 5 mL liquid LB medium, and cultivate it at 30° C. and 150 rpm for 12 hours to obtain the seed solution;

[0083] (3) Expansion cultivation: the seed liquid obtained in step (2) (viable bacteria number 1 × 10 8 CFU / mL) was transferred to LB liquid medium at a volume ratio of 1%, and cultivated to OD at 30°C and 150rpm 600 =1.0, obtain fermented liquid;

[0084] (4) Preparation of bacterial agent: the fermented liquid obtained in step (3) is centrifuged at 3600rpm for 10min, the supernatant is discarded, and then the inorganic salt liquid medium is added until the n...

Embodiment 3

[0086] Embodiment 3: the degradation ability of Stenotrophomonas maltophilia JWG-G1 to the intermediate phthalate (BHET) of polyethylene terephthalate in different addition amounts

[0087] With the bacterial agent Stenotrophomonas maltophilia JWG-G1 (viable bacteria number 2 * 10) that step (4) in the embodiment 2 obtains 9 CFU / mL) were added to the 2mg The reaction system was obtained in the inorganic salt liquid of BHET; the reaction system was placed at 37° C. and 150 rpm to react for 15 hours, and the amount of MHET and TPA generated and the remaining amount of BHET were measured by HPLC.

[0088] The analysis results are shown in Table 1. With the increase of the addition amount of Stenotrophomonas maltophilia JWG-G1, the degradation rate of BHET gradually increased; when the addition amount of Stenotrophomonas maltophilia JWG-G1 was 20%, The degradation rate of BHET reached the maximum value (37%); after that, the degradation rate of BHET remained unchanged with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com