A method for microbial treatment of phosphine tail gas

A technology for microbial treatment and phosphine, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high adsorbent consumption, difficult regeneration, and limited adsorption capacity in the purification process, and achieve good synergistic degradation effects. Good biotransformation effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

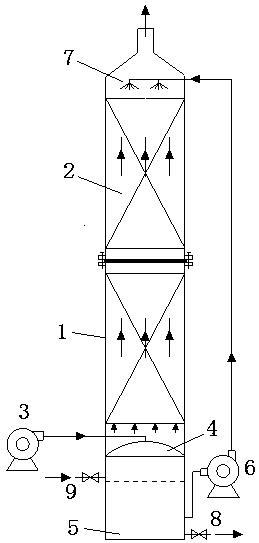

[0020] The method for microbial treatment of phosphine tail gas described in this embodiment, the processing equipment includes a cylindrical trickling filter tower 1, a packing layer 2, an intake pump 3, an aerator 4, a circulation tank 5, a circulation pump 6, a sprayer 7, The waste liquid discharge pipe 8, the liquid inlet pipe 9, the packing layer 2, the aerator 4, the circulation tank 5, and the sprayer 7 are arranged inside the trickling filter tower 1, and the sprayer 7 is arranged above the packing layer 2, and the packing layer 2 There are two layers, and a porous plate is set between the two layers, which can effectively support the filler and prevent the filler from being too dense, which is conducive to the uniform penetration of the gas-liquid two-phase. Below the device 4, the aerator 4 is connected to the intake pump 3, the circulation tank 5 is connected to the circulation pump 6, the circulation pump 6 is connected to the sprayer 7, the sprayer 7 has two nozzle...

Embodiment 2

[0023] The method for microbial treatment of phosphine tail gas described in this example adopts the same treatment equipment and process flow as in Example 1, after fully soaking ceramsite, polyurethane foam sponge and bagasse in water, the ceramsite is 60% by volume, Polyurethane foam sponge 20% and bagasse 20% form a composite filler; the absorption liquid is sodium acetate 20.0g / L, (NH 4 ) 2 SO 4 0.5g / L, MgSO 4 0.06g / L, KCl 0.3g / L, FeSO 4 0.06g / L, MnSO 4 The 0.06g / L mixed solution was diluted 20 times with Na 2 CO 3Adjust the pH value to the solution of 7.5, and the microbial domestication mode is the same as that of Example 1. During the treatment process, the intake flow rate of the tail gas containing phosphine is 15L / min, and the pH in the intake air is 15L / min. 3 The concentration is 300mg / m 3 , the oxygen volume fraction is 8%, and the liquid-gas ratio is 10L / m 3 Make sure that the spraying amount of circulating liquid is 9.0L / h, and the internal temperat...

Embodiment 3

[0025] The method for microbial treatment of phosphine tail gas described in this example adopts the same treatment equipment and process flow as in Example 1, after fully soaking ceramsite, polyurethane foam sponge and bagasse in water, the ceramsite is 60% by volume, Polyurethane foam sponge 24% and bagasse 16% form a composite filler; the absorption liquid is sodium acetate 20.0g / L, (NH 4 ) 2 SO 4 0.5g / L, MgSO 4 0.06g / L, KCl 0.3g / L, FeSO 4 0.06g / L, MnSO 4 The 0.06g / L mixed solution was diluted 20 times with Na 2 CO 3 Adjust the pH value to the solution of 7.4, and the microbial domestication mode is the same as that of Example 1. During the treatment process, the intake flow rate of the tail gas containing phosphine is 12L / min, and the pH in the intake air is 12L / min. 3 The concentration is 450mg / m 3 , the volume fraction of oxygen is 12%, and the liquid-gas ratio is 15L / m 3 Make sure that the spraying amount of circulating liquid is 10.8L / h, and the internal te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com