Fender pressure relief method for mechanically cutting tight roof at intervals

A hard roof and mechanical cutting technology, which can be used in earth drilling, ground mining, underground mining, etc., and can solve problems such as deformation and damage of roadways in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] refer to Figure 1-Figure 3 , a small coal pillar pressure relief method for mechanically cutting a hard roof at intervals, is characterized in that it comprises the following steps:

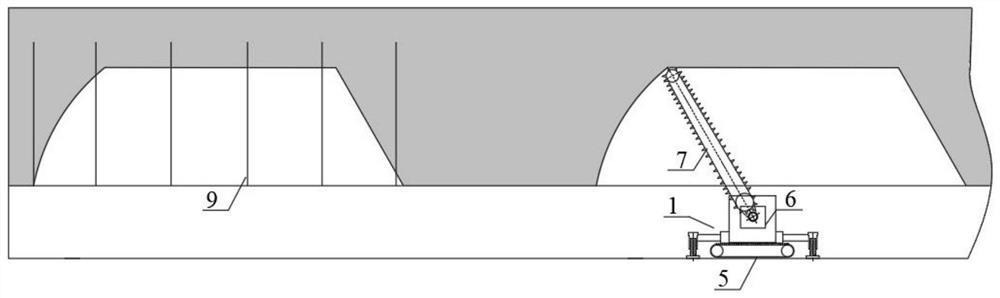

[0046] Step 1: adjust the running part 5 of the rock cutter so that the cutting tool 7 is parallel to the roadway 3;

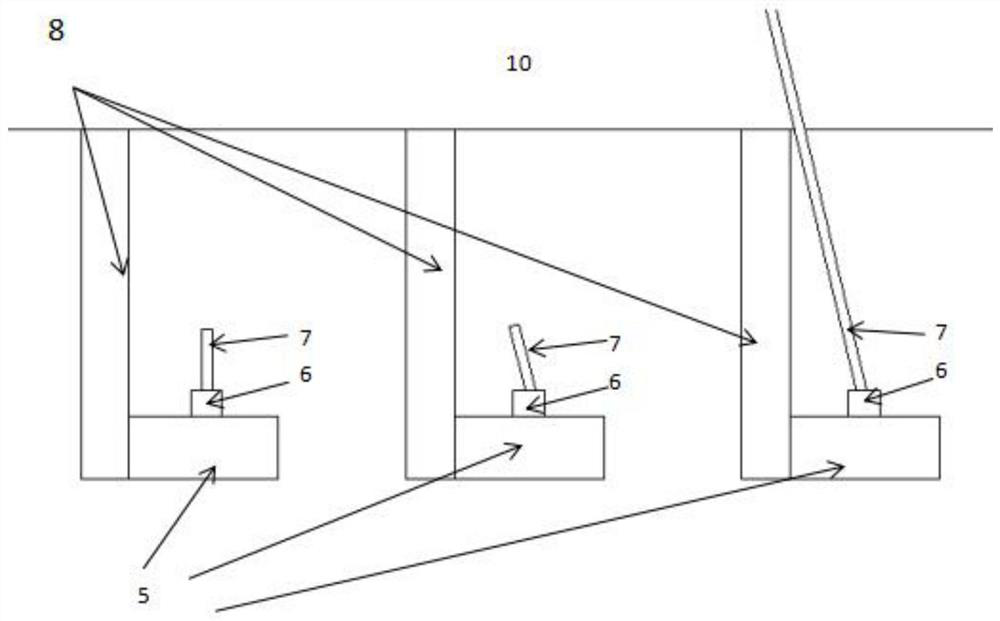

[0047] Step 2: adjust the cutting tool tilting mechanism 6 to deflect the cutting tool 7 to the coal pillar direction, and form an acute angle α with the roadway roof; the acute angle α is related to the static friction coefficient between the roof rocks,

[0048] When 0<static friction coefficient between roof rocks≤0.2, α is 70°~75°;

[0049] When 0.2<the static friction coefficient between roof rocks≤0.5, α is 75°~80°;

[0050] When the static friction coefficient between roof rocks is >0.5, α is 80°-85°.

[0051] Step 3: start the cutting tool 7, make the cutting tool 7 close to the surface of the side wall of the coal pillar 8, and adjust the upward deflection of ...

Embodiment 2

[0064] Take the airport roadway of a mine of Tongmei Group as an example. The width of the roadway is 5.3m and the height is 3.4m. The buried depth of the roadway is 450m, the vertical stress of the surrounding rock where the roadway is located is 11.2MPa, the Platts coefficient of the direct roof of the roadway is 5, the coefficient of static friction is 0.3, the size of the coal pillar is 5m, and the thickness of the coal seam is 3.4m. According to the claims, the top cutting depth is 10.2m, and the specific groove cutting process is as follows:

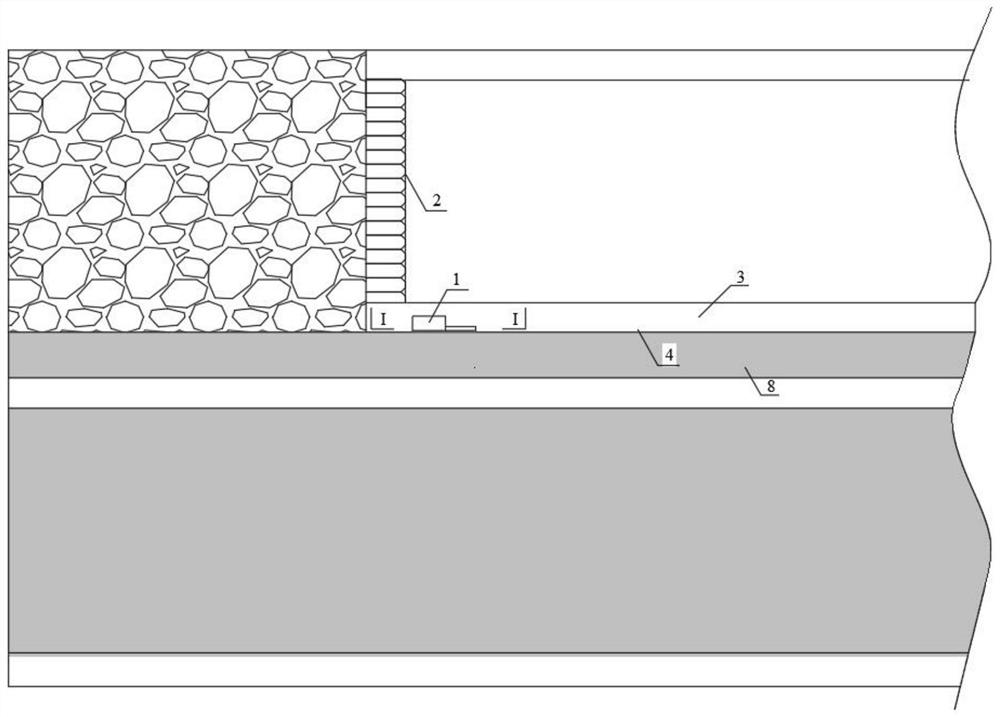

[0065] a. Park the continuous precision rock cutter on the outside 4 of the roadway at the end of the mining roadway 3 on the last working face 2;

[0066] b. Use the walking part 5 of the continuous precision rock cutter 1 to adjust the body to be parallel to the outside of the roadway, and use the cutting tool tilt adjustment mechanism 6 to adjust the cutting tool 7 so that it is biased towards the coal pillar 8 and forms an acut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com