Layered cultivation substrate for mushroom residue organic fertilizer

A cultivation substrate and organic fertilizer technology, applied in organic fertilizer, mushroom cultivation, cultivation, etc., can solve the problems of growth, flowering and even yield adverse effects, inseparable from continuous drip irrigation of nutrient solution, increased costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

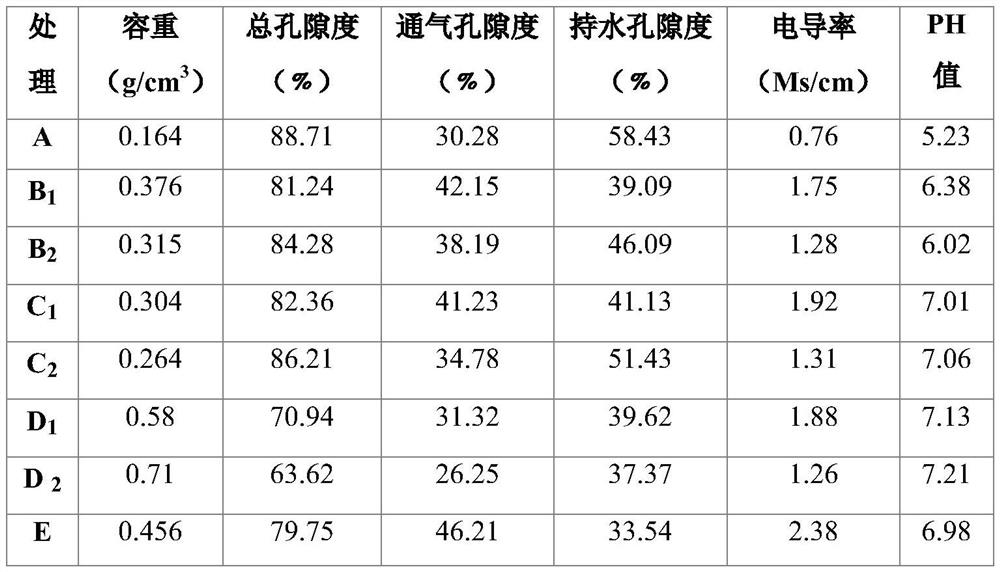

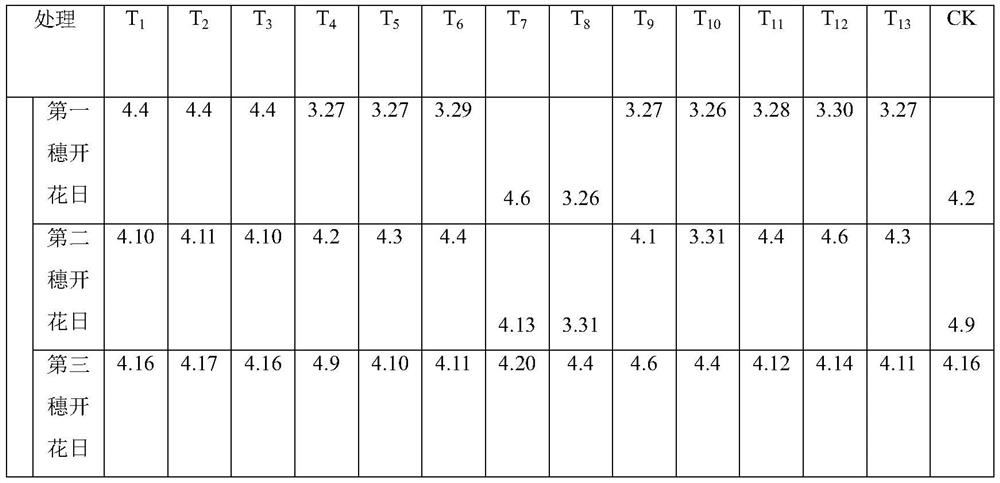

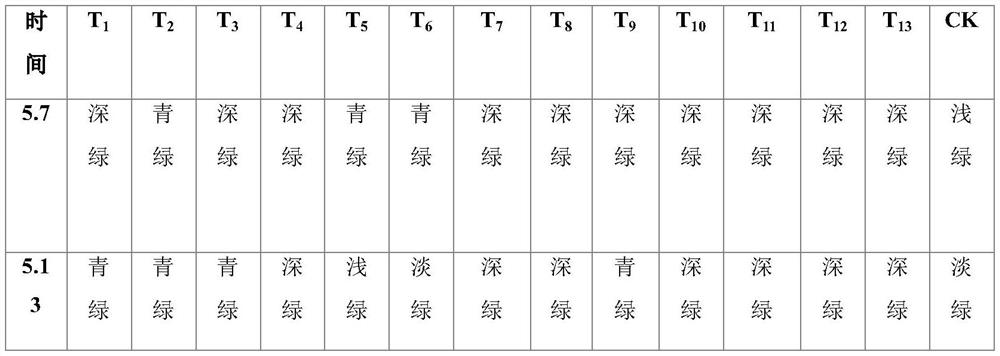

Embodiment 1

[0019] An embodiment of a mushroom dregs organic fertilizer layered cultivation substrate, which consists of a peat composite substrate layer, a first mushroom residue composite substrate layer and a second mushroom residue composite substrate layer, the peat charcoal composite substrate layer is located in the upper layer, and the first mushroom residue composite substrate layer layer is located in the middle layer, the second mushroom dregs composite matrix layer is located in the lower layer, and the composition of each layer is proportioned by volume, wherein, the peat composite matrix layer is composed of 9 parts of peat, 3 parts of vermiculite and 3 parts of perlite, with a thickness of 5cm; the first mushroom dregs composite matrix layer is composed of 70 parts of mushroom dregs organic fertilizer and 30 parts of adulterants, with a thickness of 5cm; the second mushroom dregs composite matrix layer is composed of 90 parts of mushroom dregs organic fertilizers and 10 parts...

Embodiment 2

[0024] Different from the above-mentioned embodiments, an embodiment of the layered cultivation substrate of mushroom dregs organic fertilizer is composed of a peat composite substrate layer, a first mushroom dregs composite substrate layer and a second mushroom dregs composite substrate layer, and the peat composite substrate layer is located on the In the upper layer, the first mushroom dregs composite matrix layer is located in the middle layer, and the second mushroom dregs composite matrix layer is located in the lower layer, and the components of each layer are proportioned by volume, wherein the peat composite matrix layer consists of 8 parts of peat charcoal, 2 parts of vermiculite and pearl It is made by mixing 2 parts of rock, with a thickness of 4cm; the first mushroom dregs composite matrix layer is composed of 80 parts of mushroom dregs organic fertilizer and 20 parts of adulterants, and its thickness is 4cm; the second mushroom dregs composite matrix layer is made ...

Embodiment 3

[0026] Different from the above-mentioned embodiments, an embodiment of the layered cultivation substrate of mushroom dregs organic fertilizer is composed of a peat composite substrate layer, a first mushroom dregs composite substrate layer and a second mushroom dregs composite substrate layer, and the peat composite substrate layer is located on the In the upper layer, the first mushroom dregs composite matrix layer is located in the middle layer, and the second mushroom dregs composite matrix layer is located in the lower layer. The components of each layer are proportioned by volume, wherein the peat composite matrix layer consists of 10 parts of peat charcoal, 4 parts of vermiculite and pearl 4 parts of mixed rock, with a thickness of 6cm; the first mushroom dregs composite matrix layer is composed of 60 parts of mushroom dregs organic fertilizer and 40 parts of adulterants, with a thickness of 6cm; the second mushroom dregs composite matrix layer is made of mushroom dregs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com