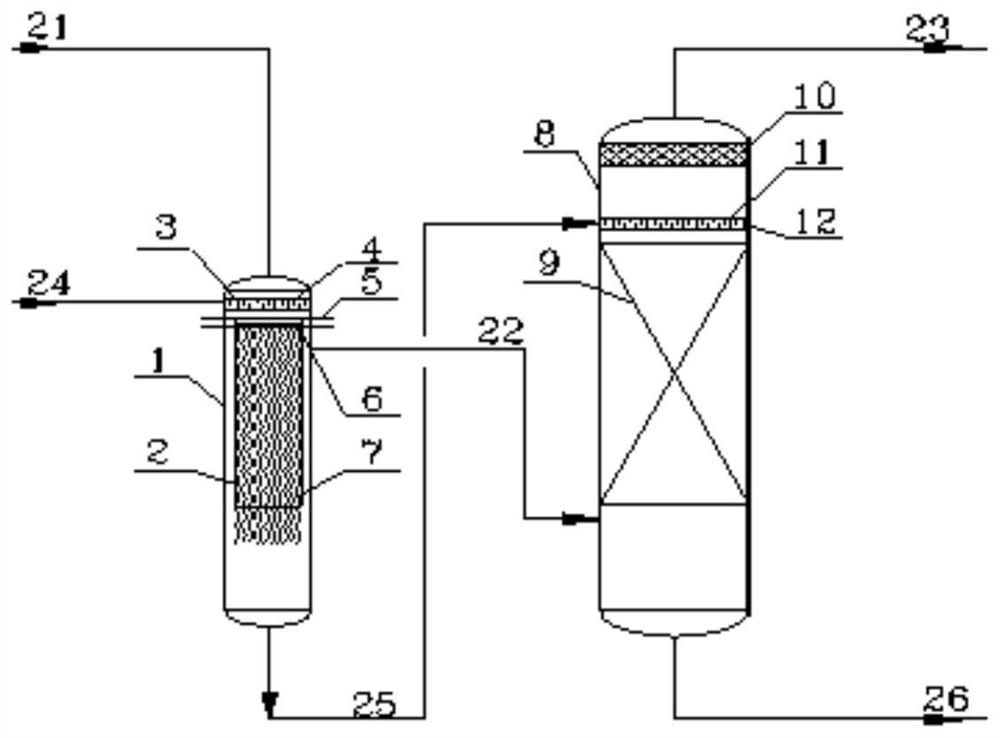

Device and method for removing hydrogen sulfide with gas-phase material liquid membrane bed

A gas-phase material and hydrogen sulfide removal technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high energy consumption for heating and cooling, large circulating flow of amine liquid, and high cost of gas-phase material desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

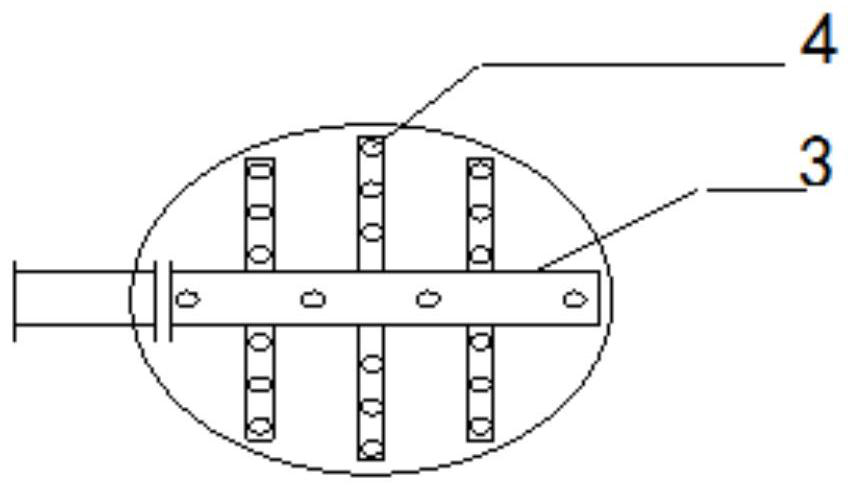

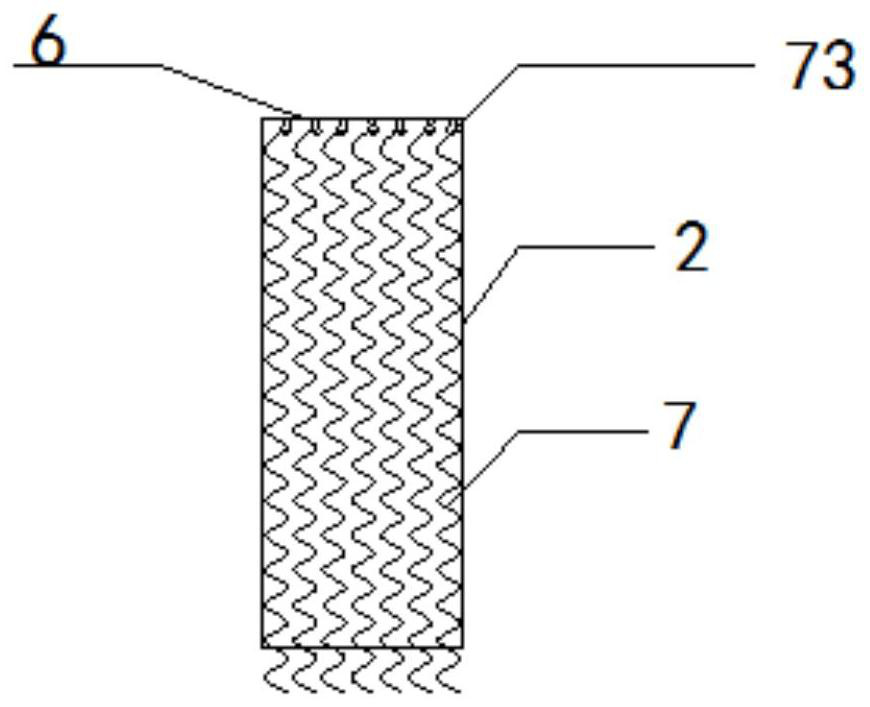

Method used

Image

Examples

Embodiment 1

[0055] The catalytic unit of an oil refinery produces dry gas materials. The dry gas material flow rate is 20000Nm3 / h, the operating pressure is 0.6MPa (G), and the hydrogen sulfide content is 30000-60000mg / m3. The two-stage amine liquid absorbs and removes hydrogen sulfide using a liquid film bed and a packed tower. Process, the amine liquid circulation flow rate is 50-55t / h, the hydrogen sulfide content in the rich amine liquid is 15-22g / L, and the hydrogen sulfide content in the dry gas material after desulfurization is less than 20mg / m3.

Embodiment 2

[0057] An oil and gas field produces natural gas with a flow rate of 100,000 to 160,000 Nm3 / h, an operating pressure of 1.2 MPa (G), and a hydrogen sulfide content of 30,000 to 50,000 mg / m3. A liquid film bed and an atomized packed tower are used for two-stage amine liquid absorption and removal of hydrogen sulfide. In the process, the flow rate of the amine liquid is 180-200t / h, the hydrogen sulfide content in the rich amine liquid is 20-25g / L, and the hydrogen sulfide content in the natural gas after removal is less than 10mg / m3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com