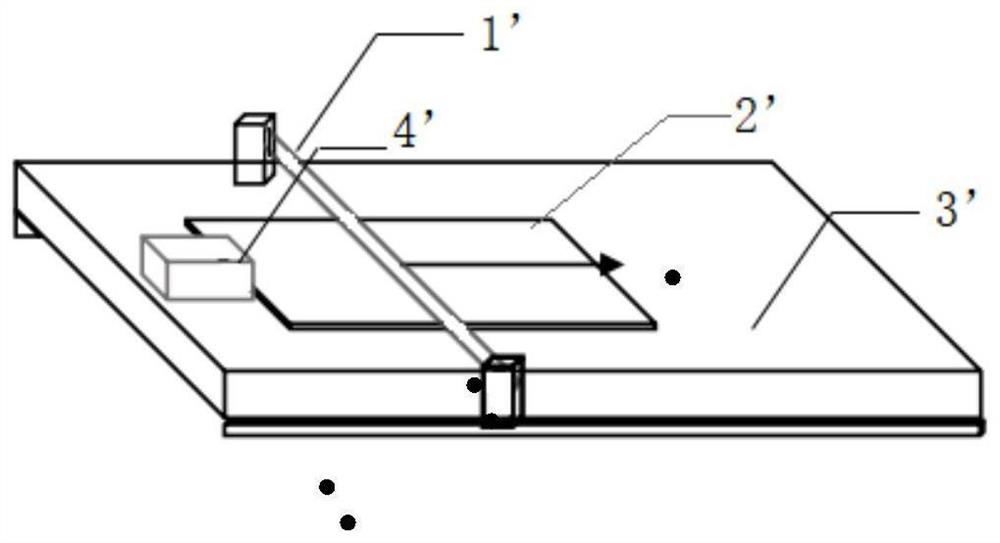

Device and method for preparing perovskite film through hot air flow blade coating

A technology of perovskite and hot air flow, which is applied in the direction of surface coating liquid devices, coatings, electrical components, etc., can solve the problem of mother liquor pollution substrate requirements, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

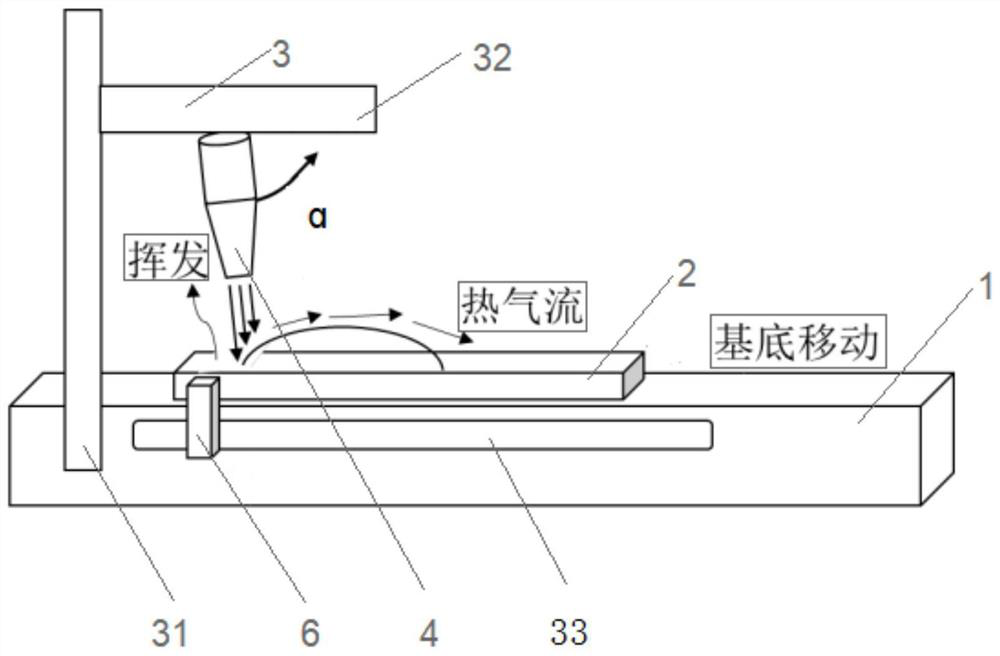

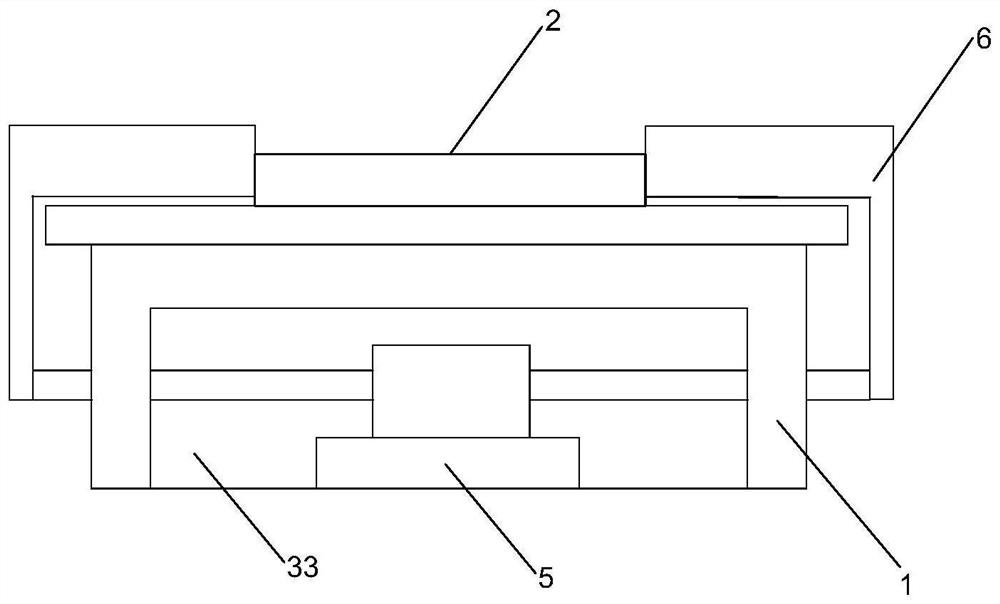

[0048] This embodiment is to utilize the hot gas flow coating method to prepare the CH of perovskite 3 NH 3 PbBr 3 film, comprising the steps of:

[0049] S1. First, place the clean substrate 2 treated with ultraviolet and ozone on the workbench 1 and fix it, then add 2mol / L mother liquor to the edge of the substrate 2 dropwise, and the dropping amount is 0.005ml / cm 2 ; Described mother liquor is DMF solvent, and raw material is the CH that molar ratio is 1:1 3 NH 3 Br and PbBr 2 ; The length of the base 2 is 2cm, and the width is 2cm;

[0050] S2. Adjust the angle between the axial and vertical directions of the spray gun 4 to be 85° and align it with the liquid droplets. The air outlet width of the used heat gun is 10mm, and the height is 1mm; the distance from the air outlet to the liquid droplets is 1cm, and the wind speed of the air gun The adjustment range is 50L / min, and the hot air temperature is 50°C;

[0051] S3. Move the support frame 3 at a moving speed of 1...

Embodiment 2

[0053] The present embodiment utilizes hot gas flow coating method to prepare perovskite (C 4 h 9 NH 3 ) 2 (CH 3 NH 3 )Pb 2 I 7 film, comprising the steps of:

[0054] S1. First, place the clean substrate 2 treated with ultraviolet and ozone on the workbench 1 and fix it, then add 1mol / L mother liquor to the edge of the substrate 2 dropwise, and the dropping amount is 0.01ml / cm 2 ; Described mother liquor is the DMF and the DMSO solvent that volume ratio is 1:1, and raw material is the C that molar ratio is 2:1:2 4 h 9 NH 3 I, CH 3 NH 3 I and PbI 2 ; The length of the base 2 is 2cm, and the width is 2cm;

[0055] S2, adjust the angle between the axial and vertical directions of the spray gun 4 to be 60° and align the liquid droplets. The air outlet width of the used heat gun is 30mm, and the height of the spray gun 4 is 2mm; the distance from the air outlet to the droplets is 2cm, and the air outlet The gun wind speed adjustment range is 500L / min, and the hot air...

Embodiment 3

[0058] This embodiment is to utilize the hot gas flow coating method to prepare the CsPbBr of perovskite 3 film, comprising the steps of:

[0059] S1. First place the clean substrate 2 treated with ultraviolet and ozone on the workbench 1 and fix it, and then add 0.1mol / L mother liquor to the edge of the substrate 2 dropwise, and the dropping amount is 1ml / cm 2 ; Described mother liquor is DMSO solvent, and raw material is CsBr and PbBr that molar ratio is 1:1 2 ; The length of the base 2 is 10cm, and the width is also 10cm;

[0060] S2, adjust the angle between the axial and vertical direction of the spray gun 4 to be 0° and align the liquid droplet. The width of the air outlet of the flat heat gun used is 100mm, and the height of the spray gun 4 is 10mm; the distance from the air outlet to the droplet is 10cm, and the air outlet The gun wind speed adjustment range is 1000L / min, and the hot air temperature is 250°C;

[0061] S3. Move the support frame 3 at a moving speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com