Fine coal separation device and processing method

A separation device and clean coal technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of reducing the separation effect of curved sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

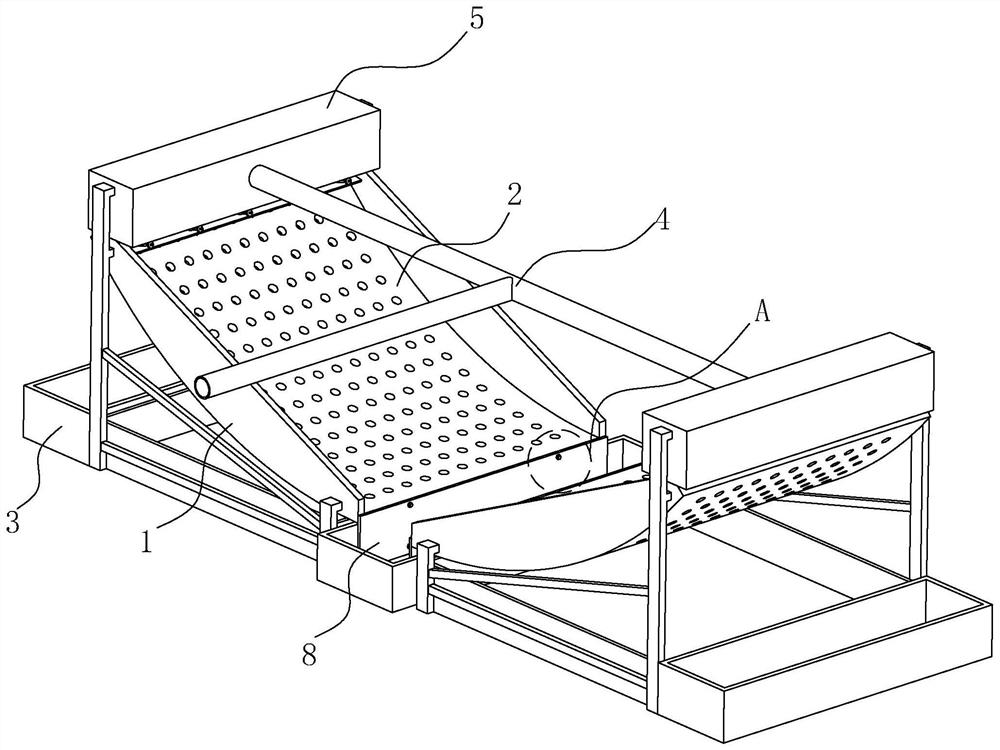

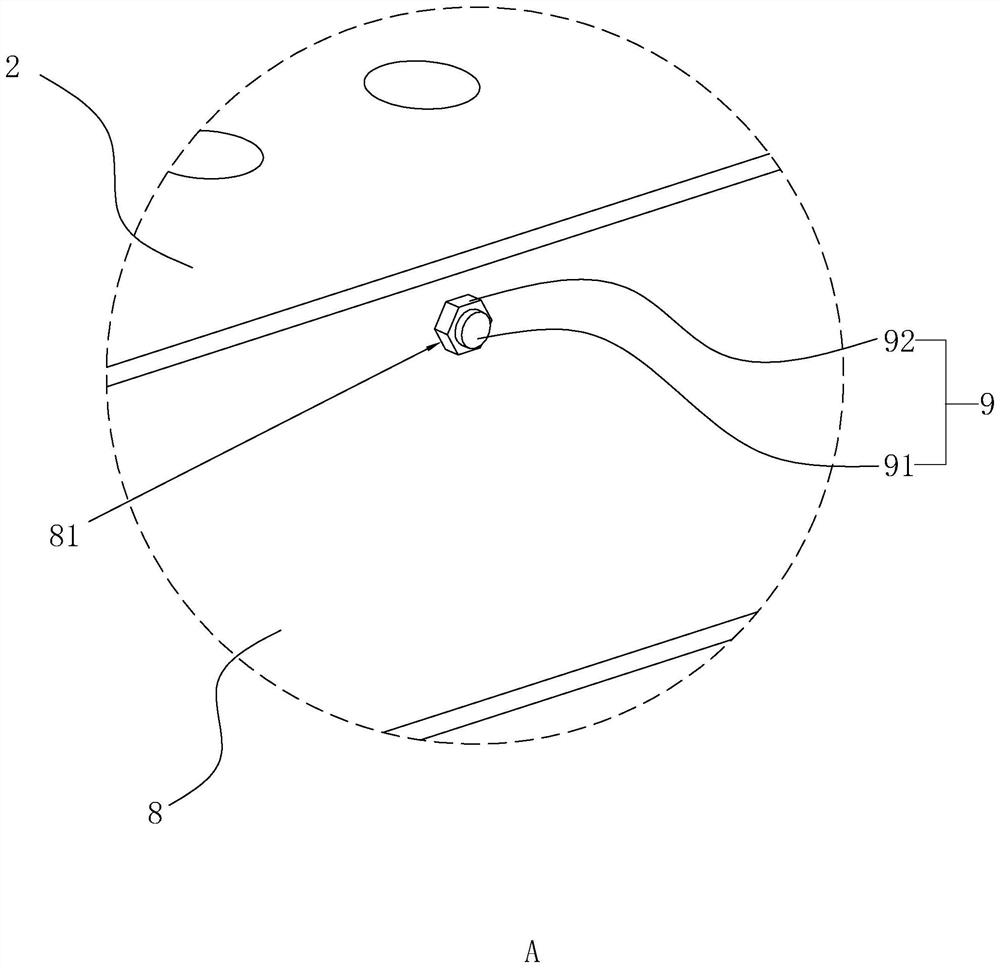

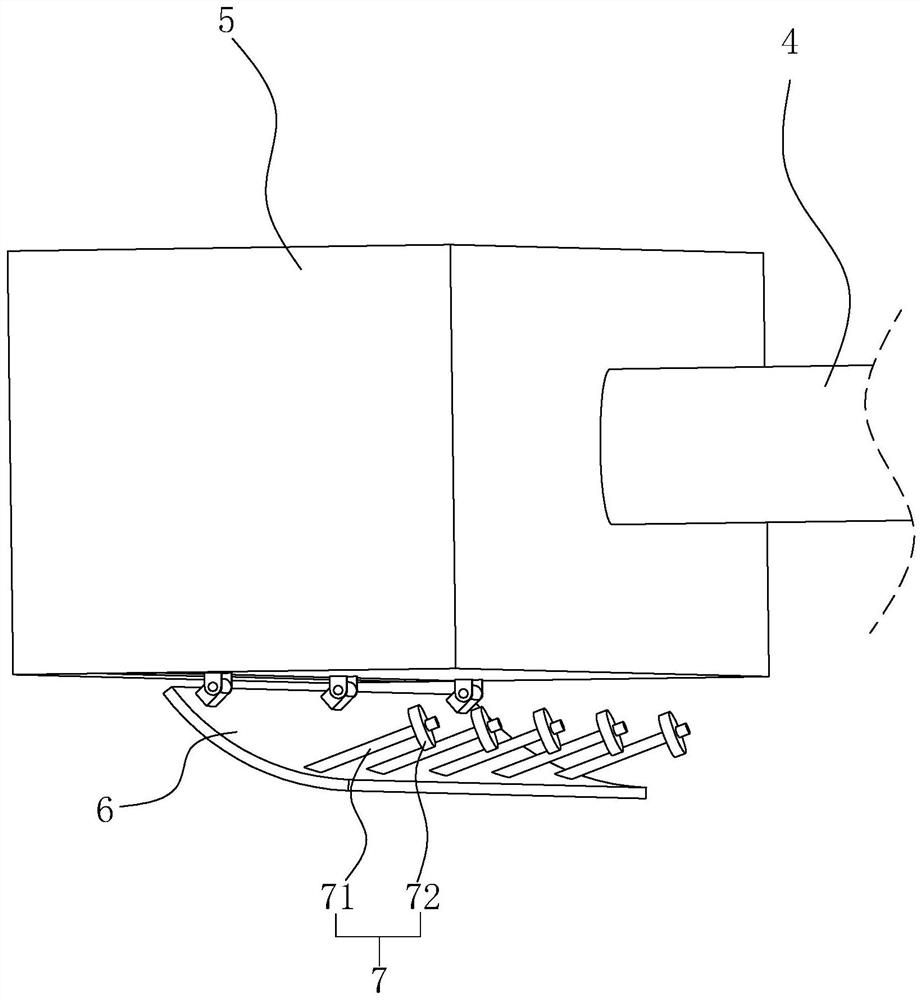

[0043] refer to figure 1 , is a curved screen 2 with a buffer device disclosed in the present invention, including a frame 1 and a curved screen 2 arranged on the frame 1, and the bottom of the curved screen 2 is provided with a collection of concentrated ore and water The pool 3 and the curved screen 2 are provided with a cleaning device 4 for water supply, and the water outlet of the cleaning device 4 is connected with a buffer box 5, and the buffer box 5 achieves the purpose of improving the separation effect of the curved screen 2.

[0044] refer to figure 1 , when using the curved screen 2, the curved screen 2 is installed on the frame 1, and the collection pool 3 is placed under the curved screen 2, the cleaning device 4 is placed above the curved screen 2, and the buffer The box 5 is placed above the top of the curved screen 2 and the buffer box 5 is connected with the cleaning device 4. After the water flows out from the cleaning device 4, it enters the buffer box 5. ...

Embodiment 2

[0050] A processing method of a clean coal separation device, comprising the following steps:

[0051] S1. Send the raw coal to the first screener for beating salvage and screening, and crush the raw coal going down the beating screen, and add the crushed raw coal and the raw coal directly sieved by the beating screen to the three-product dense medium swirl In the device, clean coal mixed with coal washing medium, medium coal mixed with coal washing medium and gangue mixed with coal washing medium are separated through the three-product dense medium cyclone;

[0052] S2, the clean coal mixed with the coal washing medium, the medium coal mixed with the coal washing medium, and the gangue mixed with the coal washing medium are respectively put into the media removal sieve for media removal to obtain the water-containing clean coal, water-containing coal and water-containing gangue after the media removal, At the same time, the qualified medium is recovered to the mixing tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com