Current control method for arc welding

A technology of current control and welding current, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of deteriorating price-performance ratio, reducing welding operation efficiency, and reducing welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

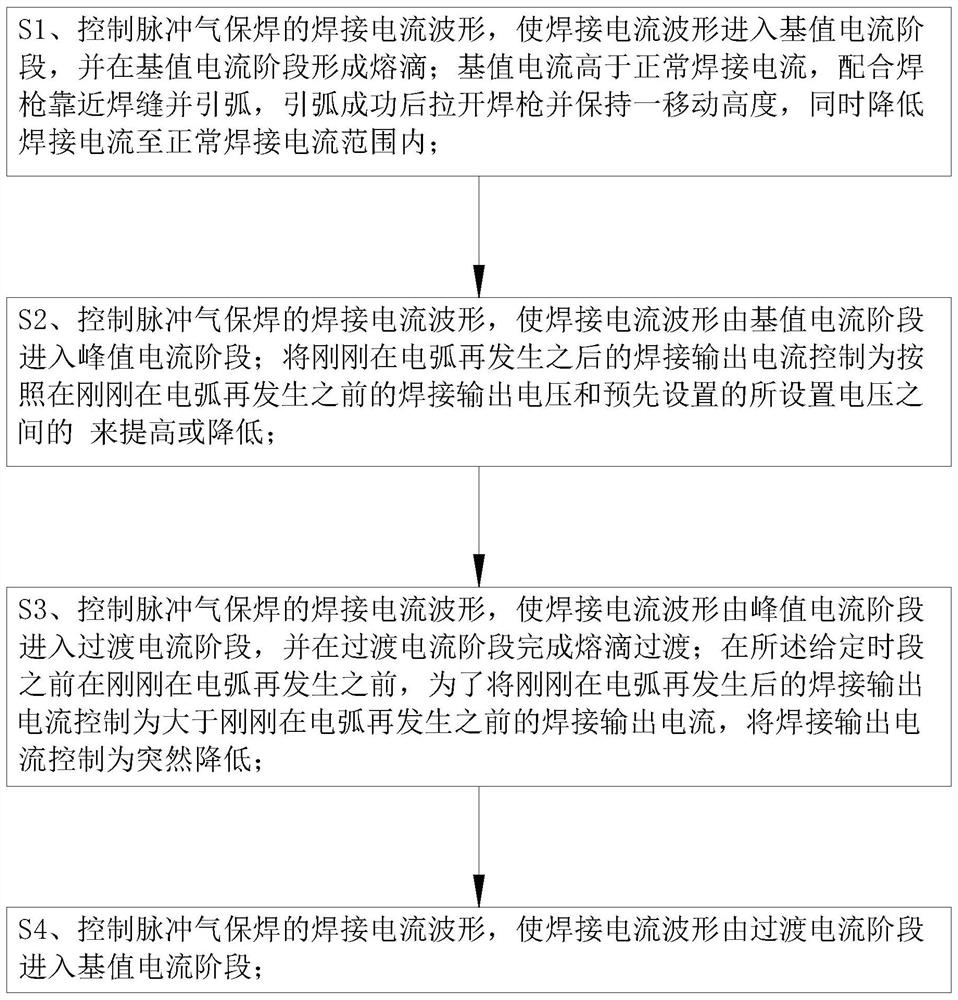

Method used

Image

Examples

Embodiment approach

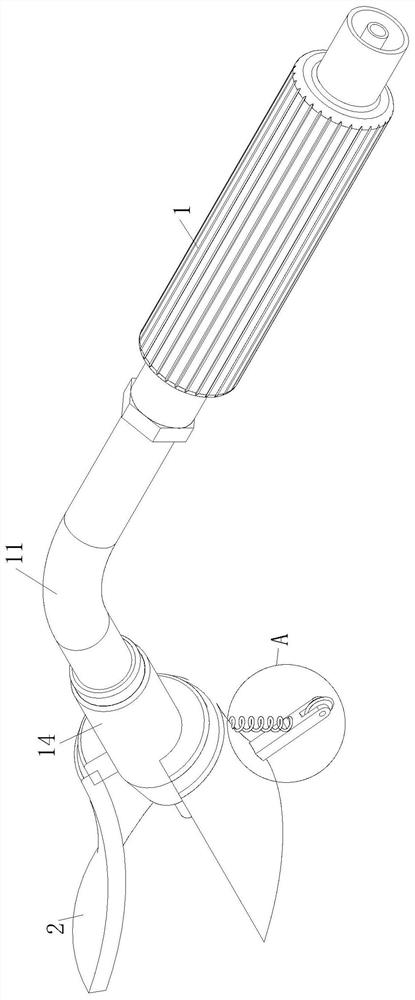

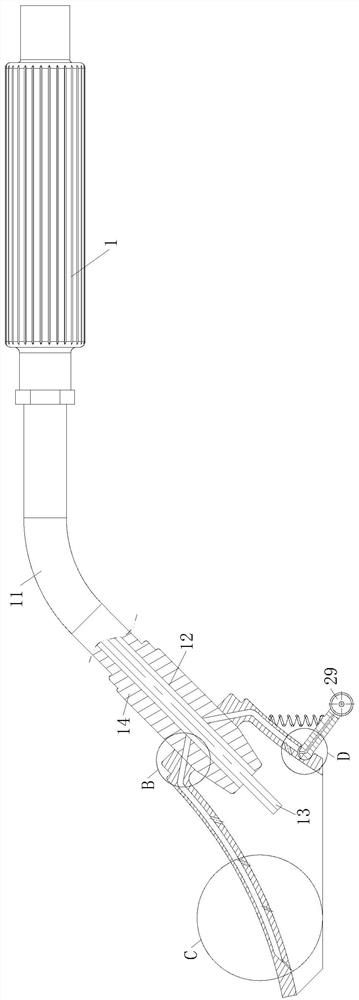

[0037] As an embodiment of the present invention, a group of arc-shaped No. 1 holes 21 that fit the contour of the protective cover 2 are evenly distributed in the side wall of the protective cover 2 along the axial direction, and the No. 1 holes 21 are close to the inner wall of the protective cover 2. There is a group of No. 2 holes 22 connected to one side of the gun head 14; a group of No. 3 holes 23 are provided at the position opposite the No. 1 hole 21 on the gun head 14. The two ends of the No. 3 holes 23 communicate with the No. 1 hole 21 and the air passage 12 respectively; The shielding gas is ejected through the No. 3 hole 23 to save the amount of shielding gas and further reduce the welding energy consumption; when a part of the shielding gas in the gas channel 12 is filled into the No. When spraying out, a thinner air curtain composed of protective gas is formed on the inner wall of the protective cover 2, thereby further isolating the air leakage at the edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com