Wastewater treatment agent, preparation method thereof and metal wastewater treatment method

A wastewater treatment agent and wastewater technology, which is applied in water treatment parameter control, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as poor effect, influence on microbial survival and reproduction, and influence on biological purification, so as to improve adsorption Effect, good adsorption effect, accelerated particle precipitation and separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-9

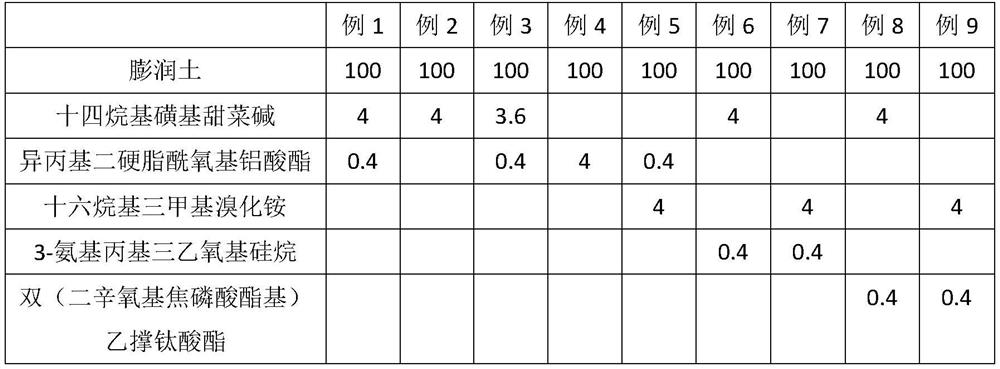

[0033] Weigh each raw material according to the data of Example 1-Example 9 corresponding to Table 1, mix evenly; add 50 grams of water and stir for 30 minutes until uniform; dry at 110°C to constant weight, and then crush into 200 mesh particles to obtain this product Invented wastewater treatment agent.

[0034] Table 1: Wastewater treatment agent raw material formula table unit: gram

[0035]

example 10

[0037] Mix 100 grams of bentonite, 4 grams of tetradecyl sulfobetaine, 1 gram of graphene oxide, 2 grams of ferrous nitrate and 0.4 gram of isopropyl distearoyloxyaluminate; add 50 grams of water and stir 30 minutes until uniform; dried at 110°C to constant weight, and then crushed into 200-mesh particles to obtain the wastewater treatment agent of the present invention.

Embodiment 1-9

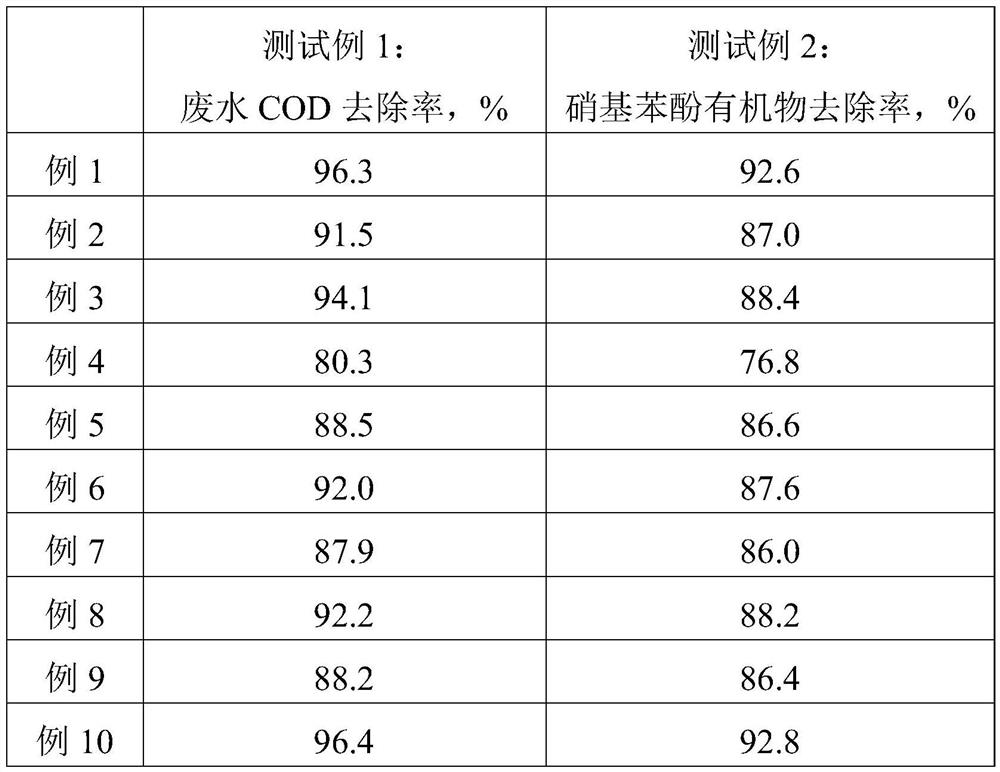

[0044] Embodiment 1-9 is analyzed:

[0045] Comparative embodiment 1 and embodiment 6 and embodiment 8, embodiment 1 adopts aluminate coupling agent, and embodiment 6 adopts silane coupling agent, embodiment 8 adopts titanate coupling agent, three tests The data vary greatly. It can be seen that the compatibility between the aluminate coupling agent and the amphoteric surfactant tetradecyl sultaine and bentonite is better, and the mutual support effect is better.

[0046] Comparative embodiment 1 and embodiment 5, the difference of the two is only: the tensio-active agent that embodiment 1 adopts is amphoteric surfactant tetradecyl sultaine, and embodiment 5 adopts cationic surfactant hexadecyl Trimethylammonium bromide; the COD removal rate of wastewater and the removal rate of nitrophenol organic matter vary greatly.

[0047] In summary,

[0048] The present invention takes bentonite as the core raw material, innovatively adopts the amphoteric surfactant tetradecyl sulfob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com