A kind of amphoteric polyacrylamide paper strengthening agent and preparation method thereof

A polyacrylamide and paper strengthening agent technology, which is applied in the direction of strengthening agent addition, can solve problems such as failure to reach customers and limited strengthening effect, and achieve the effect of improving the strengthening effect, improving the strengthening effect, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

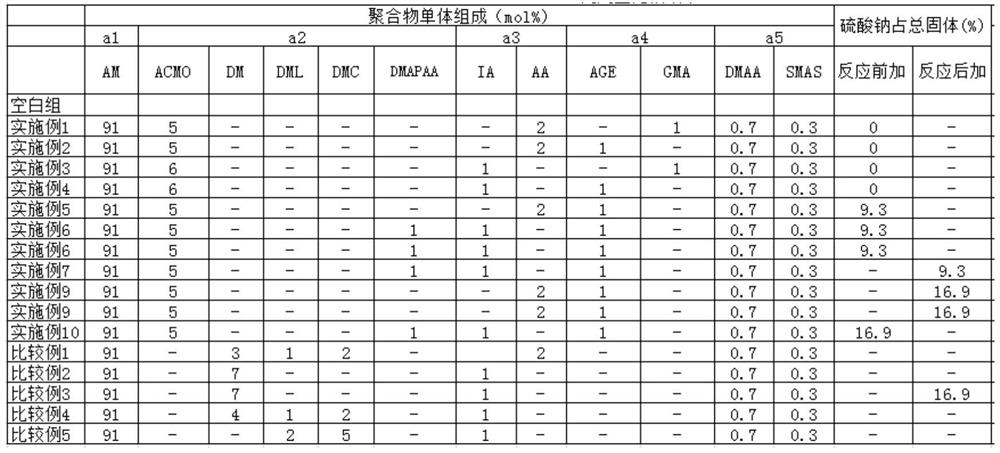

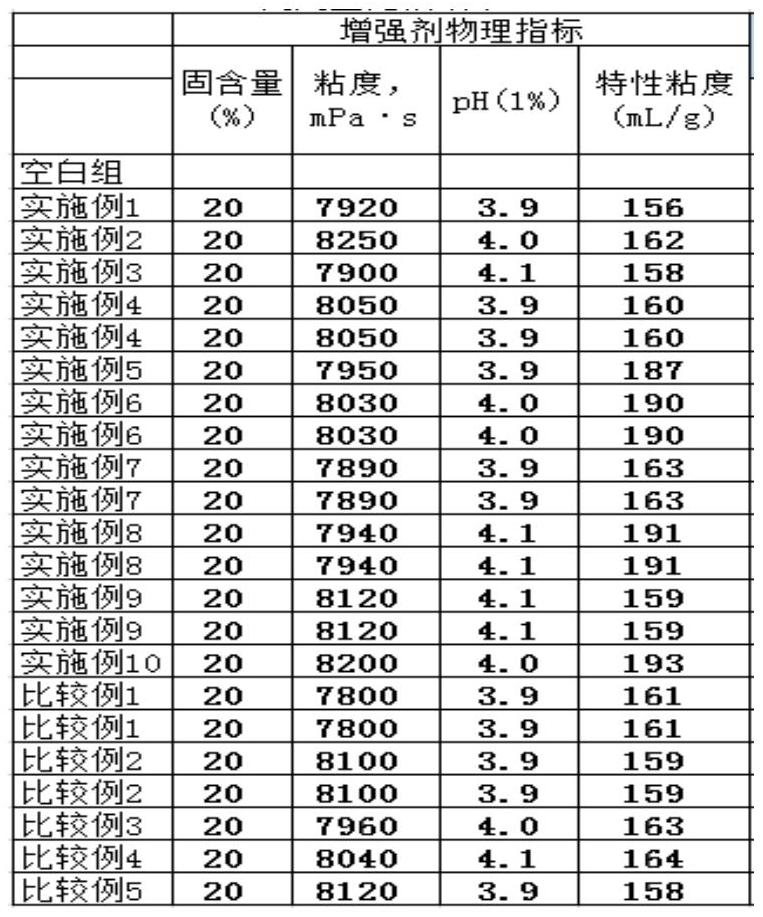

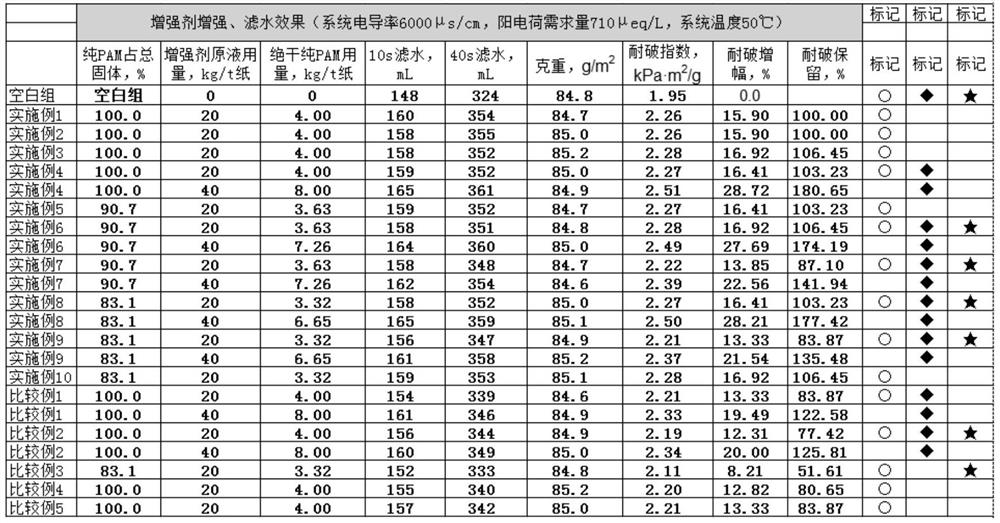

Method used

Image

Examples

Embodiment 1

[0023] Add 400.0 parts of deionized water into the reaction device with stirrer, thermometer, reflux condenser, nitrogen inlet pipe and dropping funnel, start stirring, add AM 64.6828 parts (45.5mol%), AMCO 7.0585 parts (2.5mol%) %), GMA 1.4215 parts (0.5mol%), DMAA 0.6937 parts (0.35mol%), AA 1.4412 parts (1.0mol%), SMAS 0.9489 parts (0.3mol%) and ethylenediaminetetraacetic acid 0.097 parts, stir until uniform Finally, adjust the pH of the system to 2.7-3.0 with 50% sulfuric acid. At the same time, prepare the secondary monomer in advance, that is, 100.0 parts of deionized water, 64.6828 parts of AM (45.5mol%), 7.0585 parts of AMCO (2.5mol%), 1.4215 parts of GMA (0.5mol%), 0.6937 parts of DMAA (0.35mol%) , AA 1.4412 parts (1.0mol%), after stirring until uniform, adjust the pH of the system to 2.7-3.0 with 50% sulfuric acid. Nitrogen was passed through the reaction device to remove the air in the system. When the temperature was raised to 62° C., the first initiator (0.16 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com