Preparation method of bent nano carbon fiber reinforced C/C composite material

A nano-carbon fiber and composite material technology, which is applied in the field of preparation of curved nano-carbon fiber reinforced C/C composite materials, can solve the problems of carbon fiber material damage, difficult industrial promotion, and complicated process, so as to avoid deactivation and process Simple, less damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

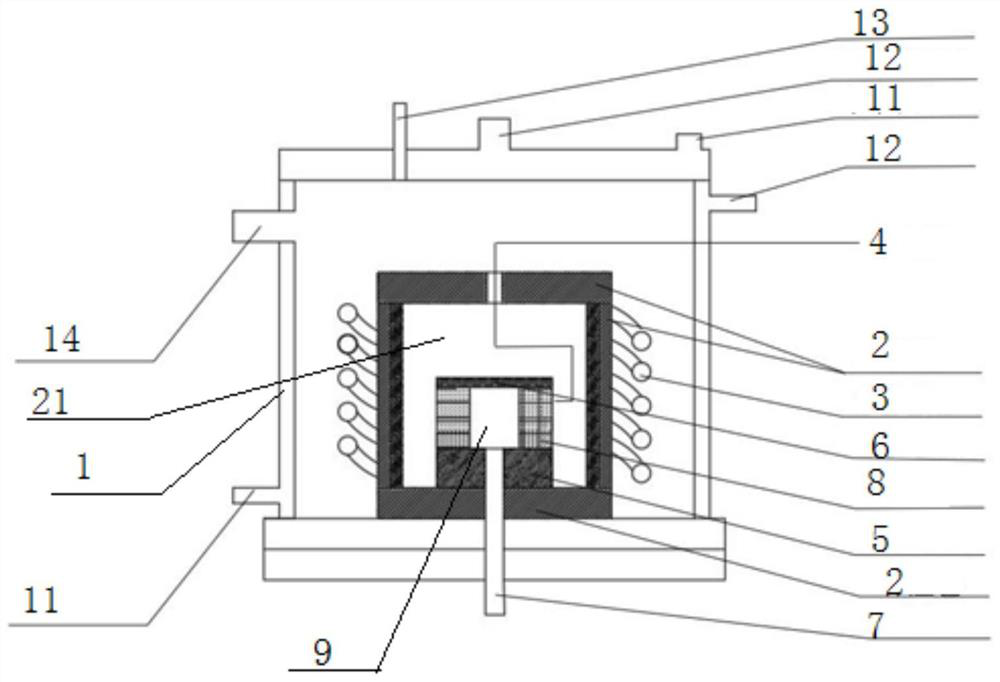

[0037] A preparation method of curved nano-carbon fiber reinforced C / C composite material, comprising the steps of:

[0038] Step S1, ultrasonically impregnating the carbon felt in a copper tartrate solution for a period of time, taking it out and drying it, wherein the concentration of the copper tartrate solution is 0.01-0.015mol / mL, and the ultrasonic impregnation time is 10-20min;

[0039] Step S2, using acetylene as the carbon source and nitrogen as the protective gas, controlling the flow rate of acetylene to 0.2-0.5L / min, and performing catalytic chemical vapor deposition at 270-290°C and working pressure of 50-80kPa, and the original growing curved nanofibers in place to obtain a carbon felt containing curved nanofibers;

[0040] Among them, in the catalytic chemical vapor deposition, the heating rate is controlled to be <3°C / min, and the catalytic chemical vapor deposition time is 30-60 minutes;

[0041] Step S3, using nitrogen as a protective gas, carbonizing the carb...

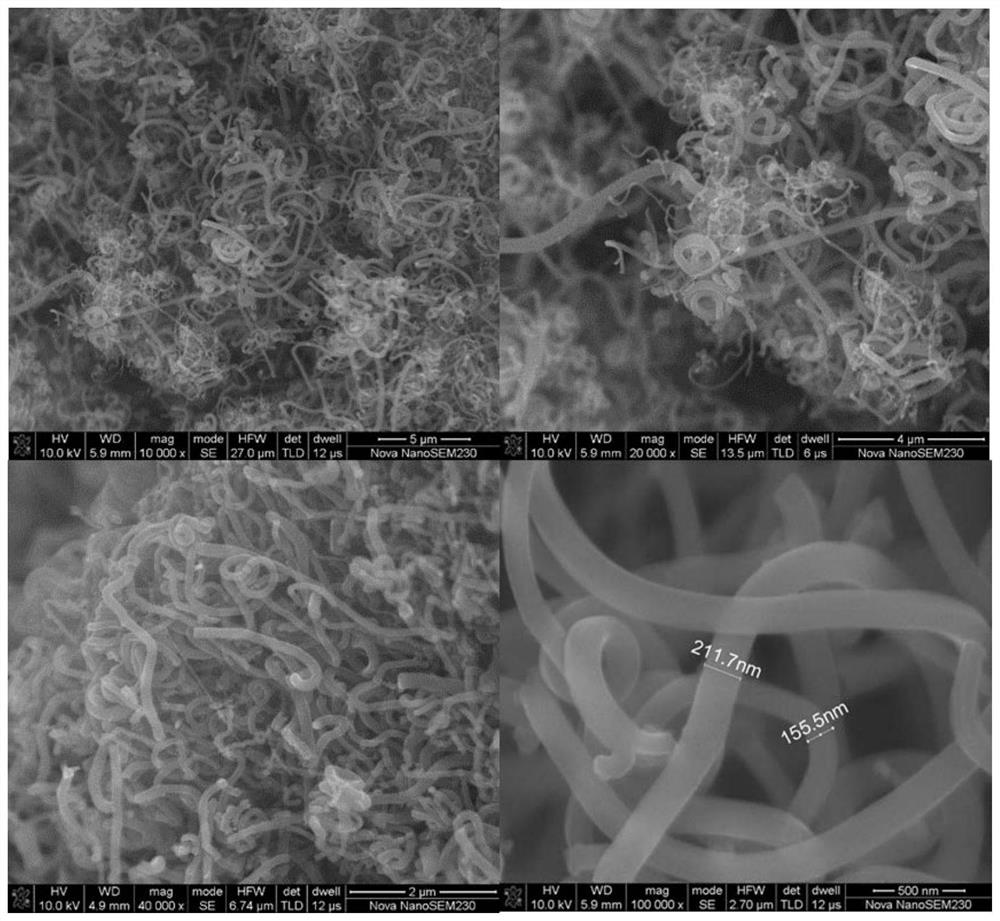

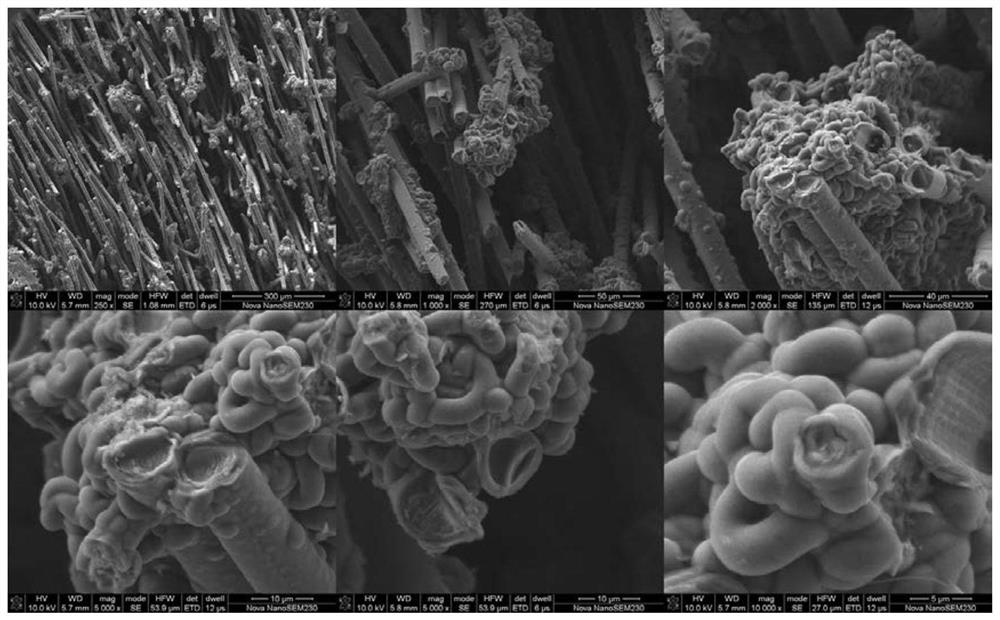

Embodiment 1

[0048] First, ultrasonically impregnate the carbon felt in 0.01mol / mL copper tartrate solution for 10min, take it out and place it in an oven at 90°C for 12h for drying; Under the condition of (acetylene)=0.3L / min, the carbon felt after impregnating copper tartrate is carried out catalytic chemical vapor deposition 30min, in situ growth curved nanofiber on carbon fiber surface, obtains the carbon felt that contains curved nanofiber; Then with Nitrogen is used as a protective gas, and the carbon felt is carbonized at 950°C to obtain a carbon felt with a mass fraction of curved nano-carbon fibers of 21.55%, wherein the diameter of the curved nano-carbon fibers is about 30-220nm, and the length is about 2-2. 15 μm; Finally, propylene is used as the carbon source, and argon is used as the carrier gas to conduct chemical vapor deposition by self-induction heating under the conditions of 950°C, 7kPa, Q (propylene) = 1.5L / min, Q (argon) = 1.5L / min The carbon felt containing curved ca...

Embodiment 2

[0051] Firstly, ultrasonically impregnate the carbon felt in 0.015mol / mL copper tartrate solution for 10min, take it out and place it in an oven at 90°C for 12h for drying; Under the condition of (acetylene)=0.3L / min, the carbon felt after impregnating copper tartrate is carried out catalytic chemical vapor deposition 60min, grows curved nanofiber in situ on the carbon fiber surface, obtains the carbon felt that contains curved nanofiber; Then with Nitrogen is used as a protective gas, and it is carbonized at 950°C to obtain a carbon felt with a mass fraction of curved nano-carbon fibers of 64.06%, wherein the diameter of the curved nano-carbon fibers is about 20-160 nm, and the length is about 10-25 μm ; Finally, with propylene as the carbon source and argon as the carrier gas, pass through the self-induction heating chemical vapor deposition furnace under the conditions of 950 ° C, 7kPa, Q (propylene) = 1.5L / min, Q (argon) = 1.5L / min The carbon felt containing curved nano-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com