Method for efficiently enriching platinum and palladium from low-concentration platinum-palladium nitric acid system solution

A low-concentration, platinum-palladium technology, applied in the direction of improving process efficiency, can solve the problems of small sediment particles, incomplete recovery, and difficulty in enriching platinum-palladium, achieving high filtration rate, improved filtration efficiency, and good precipitation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

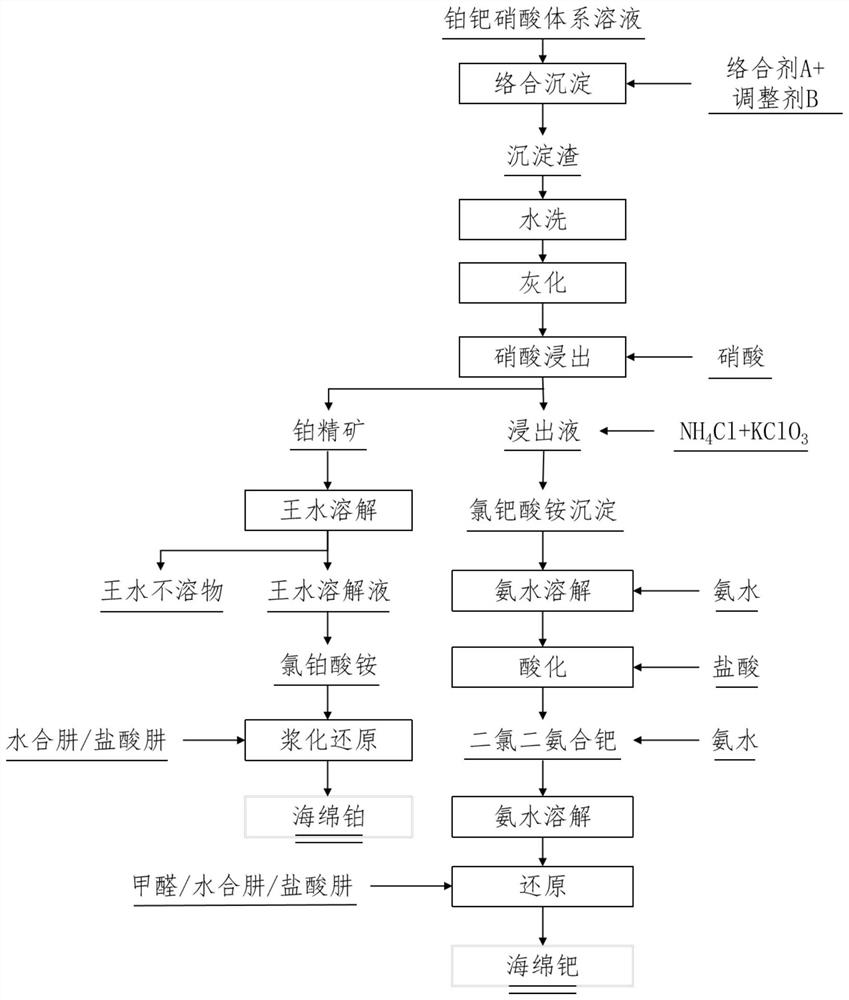

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, configuration contains platinum 0.014g / L, and the total 50L of low concentration platinum palladium nitric acid system solution containing palladium 0.03g / L is carried out according to the following steps,

[0040] 1) Put the low-platinum palladium nitric acid system solution into a 100L reaction kettle, adjust the pH to 0.7-1.5, add complexing agent A and start stirring, react at room temperature for 30-40min, then raise the temperature to 70-80°C, react for 60 -90min; then add regulator B, react for 10-20min, and filter after the reaction to obtain a platinum-palladium complex precipitate; wherein, the composition of complexing agent A is: wt85%-95% dimethylglyoxalxime and wt5%-15% of 2,4-pentanedionedioxime; the main component of regulator B is polyacrylamide, its concentration is 0.1-0.15%, and the dosage is 2-3% of the total solution;

[0041]2), washing the complex precipitate obtained in step 1) until the solution is neutral, and filtering and dryin...

Embodiment 2

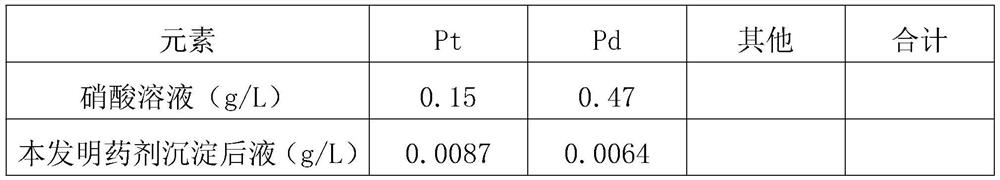

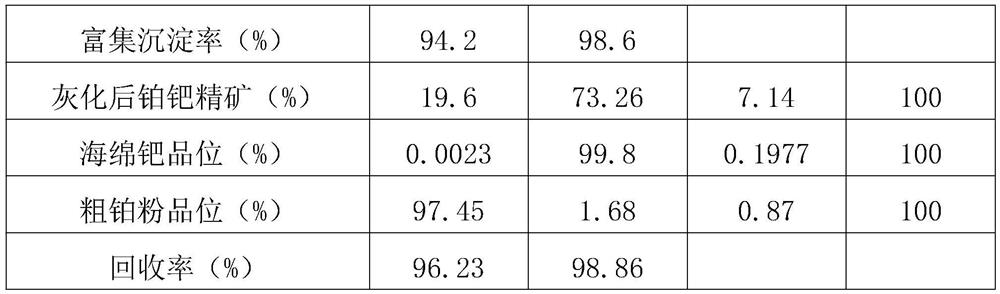

[0055] Embodiment 2, configuration contains platinum 0.15g / L, and the total 50L of the low-concentration platinum palladium nitric acid system solution containing palladium 0.47g / L is carried out according to the following steps,

[0056] 1) Put the low-platinum palladium nitric acid system solution into a 100L reaction kettle, adjust the pH to 0.7-1.5, add complexing agent A and start stirring, react at room temperature for 30-40min, then raise the temperature to 70-80°C, react for 60 -90min; then add regulator B, react for 10-20min, and filter after the reaction to obtain a platinum-palladium complex precipitate; wherein, the composition of complexing agent A is: wt85%-95% dimethylglyoxalxime and wt5%-15% of 2,4-pentanedionedioxime; the main component of regulator B is polyacrylamide, its concentration is 0.1-0.15%, and the dosage is 2-3% of the total solution;

[0057] 2), washing the complex precipitate obtained in step 1) until the solution is neutral, and filtering and d...

Embodiment 3

[0072] Embodiment 3, configuration contains platinum 0.25g / L, and the low concentration platinum palladium nitric acid system solution containing palladium 0.73g / L is totally 30L, carries out according to the following steps,

[0073] 1) Put the low-platinum palladium nitric acid system solution into a 50L reaction kettle, adjust the pH to 0.7-1.5, add complexing agent A and start stirring, react at room temperature for 30-40min, then heat up to 70-80°C, react for 60 -90min, then add regulator B, react for 10-20min, filter after the reaction, and obtain platinum-palladium complex precipitate; the composition of complexing agent A is: wt85%-95% of dimethylglyoxal oxime and wt5 %-15% of 2,4-pentanedionedioxime; the main component of regulator B is polyacrylamide, its concentration is 0.1-0.15%, and the dosage is 2-3% of the total solution;

[0074] 2), washing the complex precipitate obtained in step 1) until the solution is neutral, and filtering and drying the precipitate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com