Textured coating for improving ballistic resistance of ceramic and preparation method thereof

A ceramic and texture technology is applied in the field of textured coatings for improving the ballistic resistance of ceramics and their preparation, which can solve problems such as being easily penetrated, and achieve the purpose of preventing large-area fragmentation, improving ballistic resistance, and increasing bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

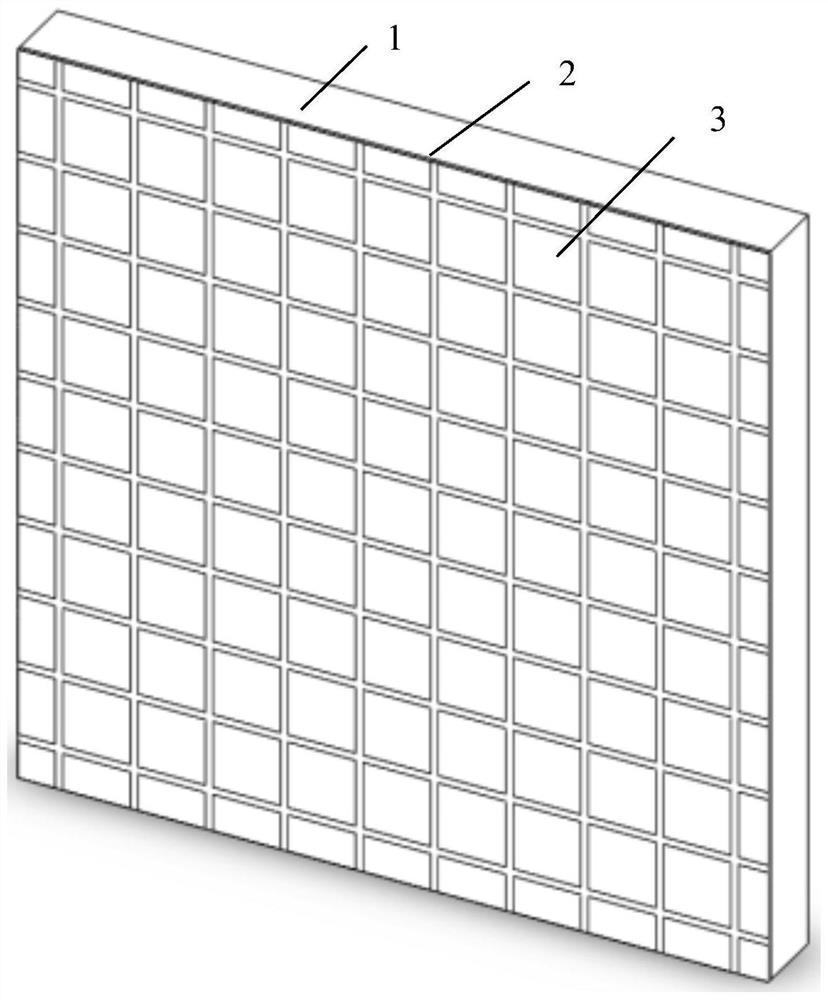

[0034] Such as figure 1 As shown, a textured coating to improve the bulletproof ability of ceramics includes a metal layer 2 and a grid layer 3 arranged on the ceramic substrate 1 from bottom to top in sequence, and the grid outline of the grid layer 3 is depressed to form interweaving grooves Grooves, the grooves form a guiding effect on the crack propagation of the ceramics, so as to prevent large-scale fragmentation of the ceramics, and the grid layer 3 is a square grid.

[0035] The preparation method of the above-mentioned textured coating for improving the ballistic resistance of ceramics: the method comprises the following steps:

[0036] (1) Ceramic surface roughening treatment: Ceramic substrate 1 is subjected to sandblasting roughening treatment before preparing the texture coating; sandblasting equipment is used to roughen the ceramic surface, the sandblasting pressure is 0.5MPa, and the sand particles are brown Corundum, the particle size is 60 mesh, the sandblast...

Embodiment 2

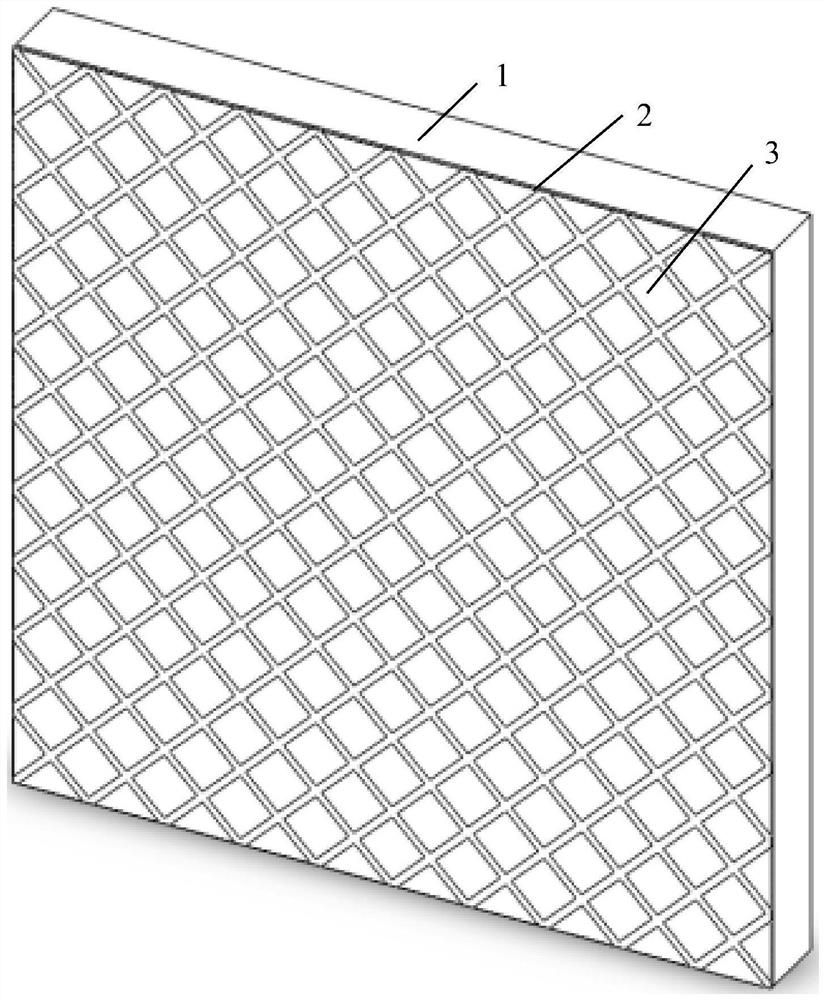

[0043] Such as Figure 2-3 As shown, on the basis of Example 1, the shape of the metal mesh is rhombus, and the side length is 25mm.

Embodiment 3

[0045] On the basis of Example 1, the shape of the metal mesh is a square with a side length of 35 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com