Bi-component water-borne printing binder, and preparation method and application thereof

A water-based printing glue, two-component technology, applied in the field of apparel processing, can solve the problems of non-conformity, softness and comfort of denim fabrics, reduce the use of organic amines, and avoid excessive crosslinking of isocyanate groups , human-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

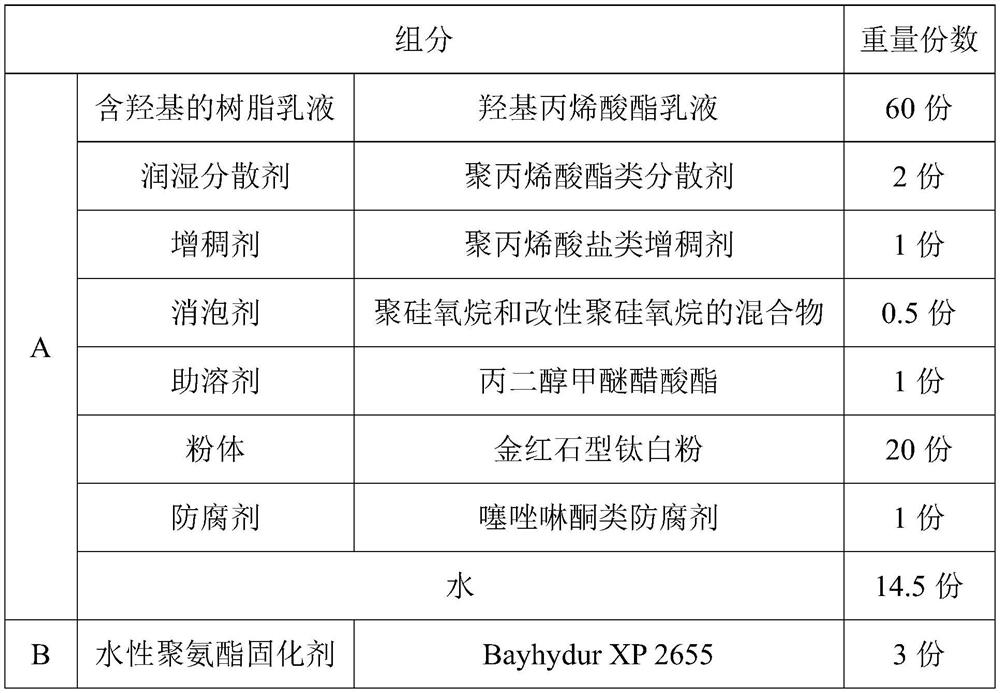

[0052] This embodiment provides a two-component water-based printing glue, the two-component water-based printing glue includes A component and B component, and the A component and B component include the following components in parts by weight , wherein the mass ratio of A component and B component is 100:3;

[0053]

[0054] The preparation method of the two-component water-based printing glue provided in this embodiment comprises the following steps:

[0055] (1) Mix and stir the hydroxyl-containing resin emulsion, wetting and dispersing agent and defoamer at a speed of 500r / min for 10min until uniform, to obtain the first mixture;

[0056] (2) Mix and stir the powder, the co-solvent and the first mixture obtained in step (1) at a speed of 1100r / min for 30min until there are no obvious large particles to obtain the second mixture;

[0057] (3) Mix and stir the thickener, preservative and the second mixture obtained in step (2) at a speed of 1600r / min for 8 minutes until...

Embodiment 2

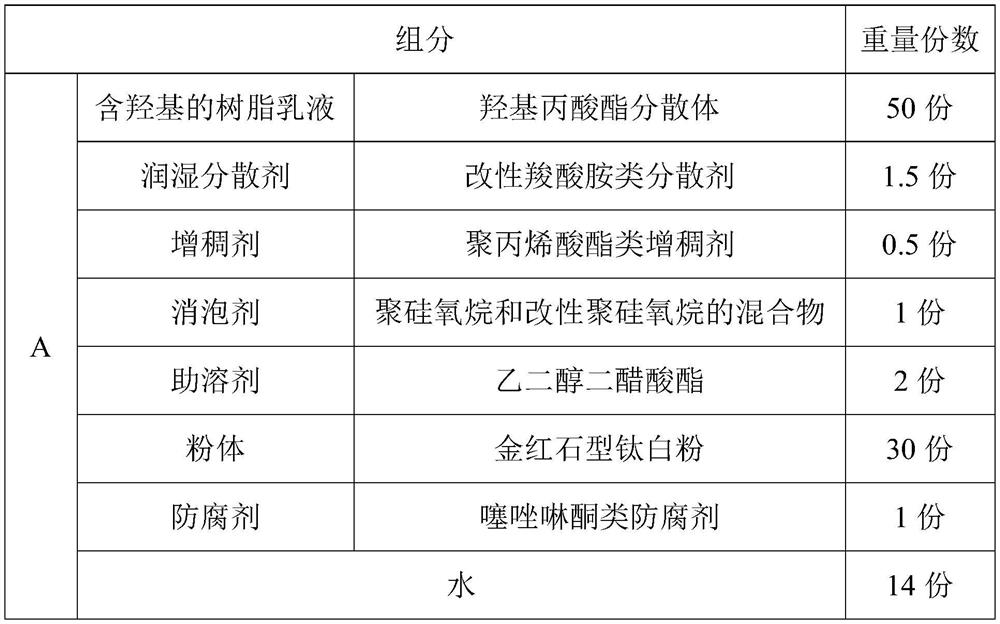

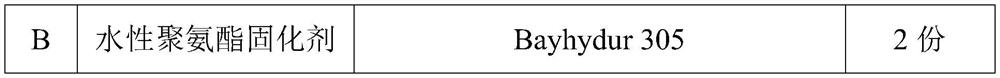

[0061] This embodiment provides a two-component water-based printing glue, the two-component water-based printing glue includes A component and B component, and the A component and B component include the following components in parts by weight , wherein the mass ratio of A component and B component is 100:3;

[0062]

[0063]

[0064] The preparation method of the two-component water-based printing glue provided in this embodiment comprises the following steps:

[0065] (1) Mix and stir the hydroxyl-containing resin emulsion, wetting and dispersing agent and defoamer at a speed of 550 r / min for 12 minutes until uniform, to obtain the first mixture;

[0066] (2) Mix and stir the powder, the co-solvent and the first mixture obtained in step (1) at a speed of 1000r / min for 35min until there are no obvious large particles to obtain the second mixture;

[0067] (3) Mix and stir the thickener, preservative and the second mixture obtained in step (2) at a speed of 1600r / min f...

Embodiment 3

[0071] This embodiment provides a two-component water-based printing glue, the two-component water-based printing glue includes A component and B component, and the A component and B component include the following components in parts by weight , wherein the mass ratio of A component and B component is 100:5;

[0072]

[0073]

[0074] The preparation method of the two-component water-based printing glue provided in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com