Piling and bridging construction all-in-one machine and construction method thereof

A construction method and an all-in-one machine technology, applied in the direction of erecting/assembling bridges, bridges, sheet pile walls, etc., can solve problems such as long period, long construction period, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

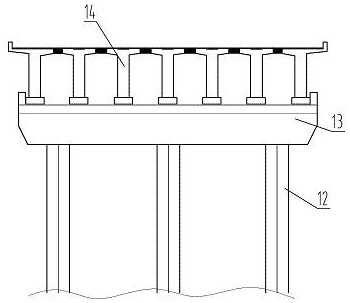

[0035] This embodiment takes figure 2 The shown viaduct is a construction object, to describe the concrete structure of the present invention and its construction operation process. Such as figure 2 As shown, the bridge pier in the same row includes three bridge piles 12, and a cover beam 13 is erected and installed on the top of the three bridge piles 12, and a box girder 14 is erected on the cover beams 13 of two adjacent rows of bridge pile piers. The top of the beam 14 is the bridge deck.

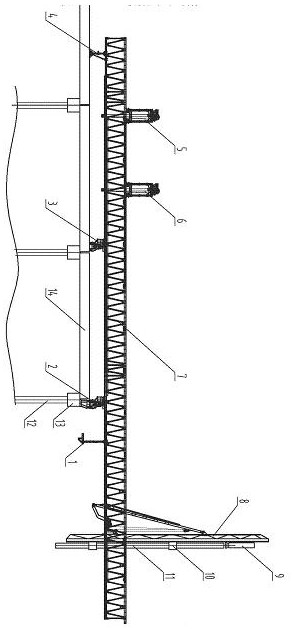

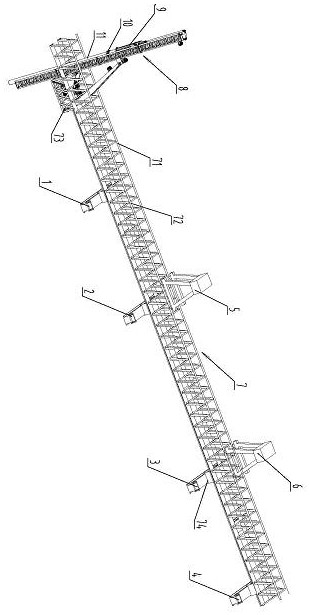

[0036] Such as figure 1 , image 3 The piling and bridge construction integrated machine shown includes a main girder 7, and the lower side of the main girder 7 supports a front outrigger 1, a middle one leg 2, a middle two outrigger 3 and a rear outrigger 4 in turn, and the front outrigger 1. The middle one leg 2, the middle two legs 3 and the rear leg 4 are laterally movably supported on the lower side of the main beam 7 through their respective traversing slide rails 74, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com