Solar thermal collector system with heat loss calculation function

A technology of solar heat collectors and heat collectors, which is applied in the field of heat collecting tubes, can solve the problems of low intelligence, high temperature, and low heat exchange efficiency, so as to improve heat transfer speed, avoid uneven heating, and realize pressure balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

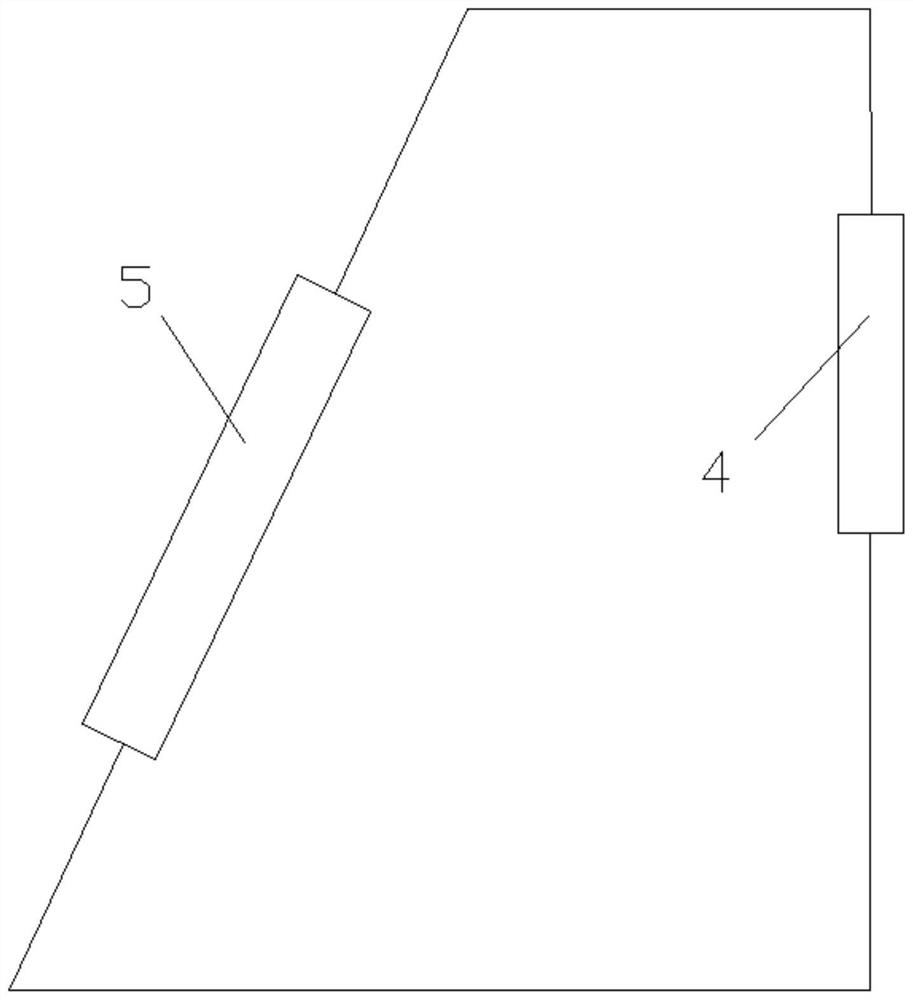

[0107] As an improvement, the central controller 7 automatically controls the opening and closing of the valves 13, 15 according to the detected indoor temperature and the temperature of the water entering the radiator.

[0108] Preferably, valve 15 is open and valve 13 is closed during normal operation.

[0109] If the indoor temperature is higher than the water temperature entering the radiator, the central controller 7 automatically controls the valve 15 to close, and the valve 13 is opened simultaneously. Ensure that water does not enter the radiator, because if water enters the radiator 4 at this time, not only does not play the effect of heat dissipation, but the heat in the room is transferred to the water, thereby reducing the heat dissipation effect. Energy can thus be saved by this measure.

[0110] If the water temperature detected by the bypass pipeline temperature sensor 12 is higher than the indoor temperature, the central controller automatically controls the v...

Embodiment 2

[0117] As an improvement, the central controller 7 automatically controls the opening and closing of the valves 13, 15 according to the detected temperature of the inlet pipe of the radiator 4, the temperature of the water in the outlet pipe of the heat collector and the temperature of the bypass pipe.

[0118] If the temperature of the radiator inlet pipe detected by the central controller 7 is lower than the indoor temperature of the radiator, the central controller 7 automatically closes the valve 15 and opens the valve 13 . Opening the valve 13 can ensure that the water between the valves 11 and 15 can be circulated to the heat collector through the bypass pipeline for heating, and at the same time, the water between the valves 13 and 15 that does not meet the temperature requirement can be drained. The water in the collector pipe 2 continues to be heated by solar energy. When the water temperature in the outlet pipe of the collector exceeds a certain value of the indoor te...

Embodiment 3

[0129] If the temperature of the radiator inlet pipe detected by the central controller 7 is lower than the indoor temperature of the radiator, the central controller 7 automatically closes the valves 11 and 15 and opens the valve 13 . The water in the heat collecting pipe 2 continues to be heated by solar energy. When the water temperature in the heat collecting pipe 2 exceeds a certain value of the indoor temperature, preferably more than 10 degrees Celsius, the valve 11 is opened, and the water flows through the bypass pipe. If the bypass pipe sensor 12 When the detected water temperature exceeds a certain degree in the room, such as 5 degrees Celsius, the bypass pipeline valve 13 is closed, and the radiator pipeline valve 15 is opened, so that water enters the radiator to dissipate heat.

[0130] Through the above measures, the temperature of the water is detected through the bypass pipeline, which further improves the heat dissipation effect and improves the intelligent co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com