Silicon-doped iron-nitrogen/carbon composite catalyst as well as preparation method and application thereof

A catalyst, silicon doping technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., to achieve the effect of simple and easy method, improved service life, and high methanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

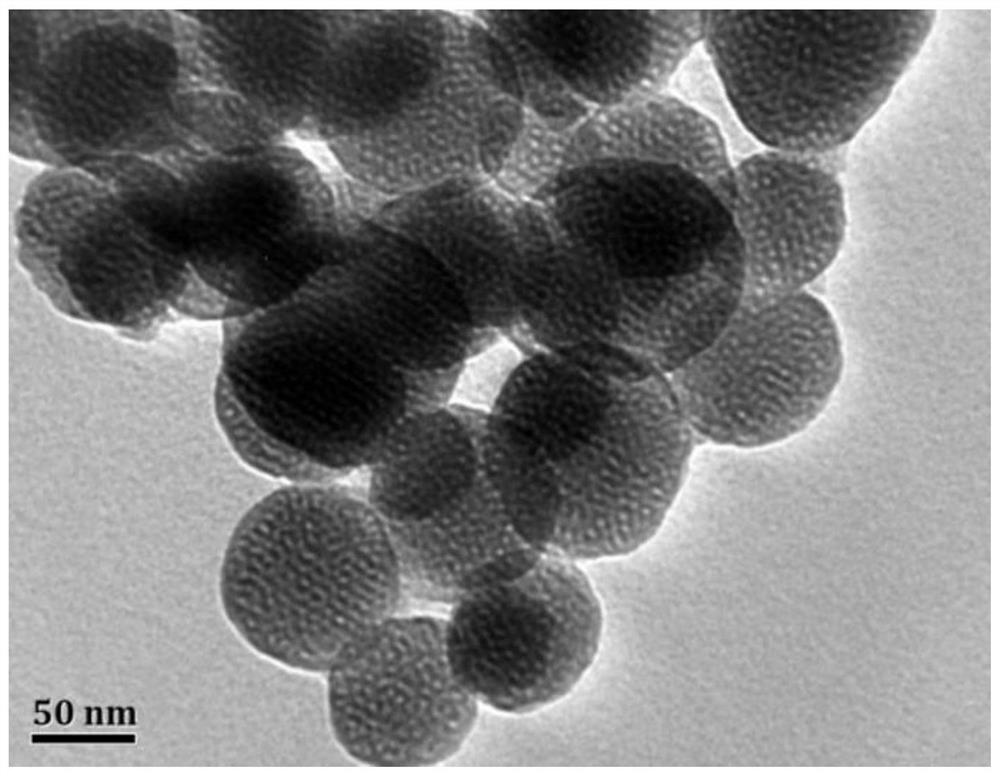

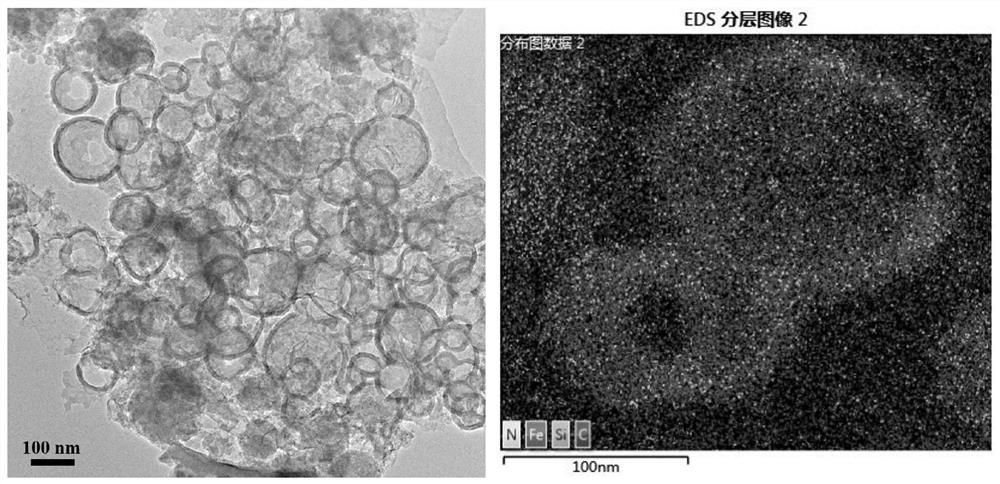

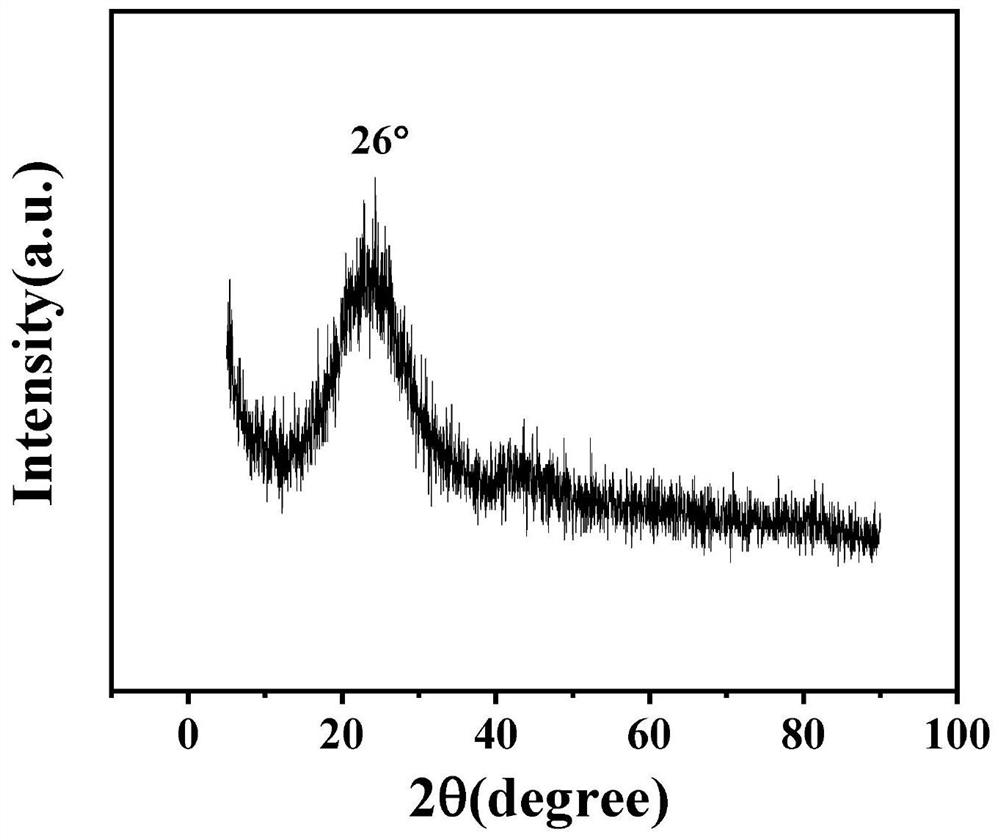

[0042] In this embodiment, a method for preparing a silicon-doped iron-nitrogen / carbon composite catalyst comprises the following steps:

[0043] a. Using cetyltrimethylammonium bromide (CTAB) template to synthesize mesoporous silica silica spheres, the synthesis method is as follows:

[0044] Under stirring conditions, 1.0 g of cetyltrimethylammonium bromide was dissolved in 160 mL of deionized water, and 7.0 mL of concentrated ammonia water with a concentration of 15% by mass was added dropwise to form a transparent solution; Add the mixed solution of ethyl orthosilicate and 20mL of n-hexane dropwise into the above transparent solution; through the reaction, at 35°C and at a speed of 200rpm, the mixed solution gradually becomes a milky white colloidal solution; keep stirring for 12h After cooling down to room temperature, the product was collected by centrifugation, and the collected product was washed with deionized water and ethanol; then the collected product was dried at...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, especially in that:

[0061] In this embodiment, a method for preparing a silicon-doped iron-nitrogen / carbon composite catalyst comprises the following steps:

[0062] a. Using cetyltrimethylammonium bromide (CTAB) template to synthesize mesoporous silica silica spheres, the synthesis method is as follows:

[0063] Under stirring conditions, 1.0 g of cetyltrimethylammonium bromide was dissolved in 160 mL of deionized water, and 4.0 mL of concentrated ammonia water with a concentration of 15% by mass was added dropwise to form a transparent solution; Add the mixed solution of ethyl orthosilicate and 30mL of n-hexane dropwise into the above transparent solution; through the reaction, at 35°C and at a speed of 200rpm, the mixed solution gradually turns into a milky white colloidal solution; keep stirring for 12h After cooling down to room temperature, the product was collected by centrifugation, and the collected prod...

Embodiment 3

[0069] This embodiment is basically the same as the previous embodiment, and the special features are:

[0070] In this embodiment, a method for preparing a silicon-doped iron-nitrogen / carbon composite catalyst comprises the following steps:

[0071] a. This step is the same as in Embodiment 1;

[0072] b. This step is the same as in Embodiment 1.

[0073] In this example, the application of a silicon-doped iron-nitrogen / carbon composite catalyst, the preparation method of the silicon-doped iron-nitrogen / carbon composite catalyst described in this example is used to prepare the silicon-doped iron-nitrogen / carbon composite catalyst to prepare the catalyst Suspension, the preparation method of the catalyst suspension is as follows: use the silicon-doped iron-nitrogen / carbon composite catalyst as the oxygen reduction catalyst material, take 5mg of silicon-doped iron-nitrogen / carbon composite catalyst, add 10mL ethanol and 10 μL concentration 5wt% Nafion solution, mixed, and ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com