Preparation machine of cooling liquid for band saw blade grinding and use method

A cooling liquid and compounding machine technology, which is applied in mixing methods, chemical instruments and methods, mixers with rotating containers, etc., can solve problems such as fixed mixing area, unreasonable design of mixing components, and settlement, so as to achieve good uniformity of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

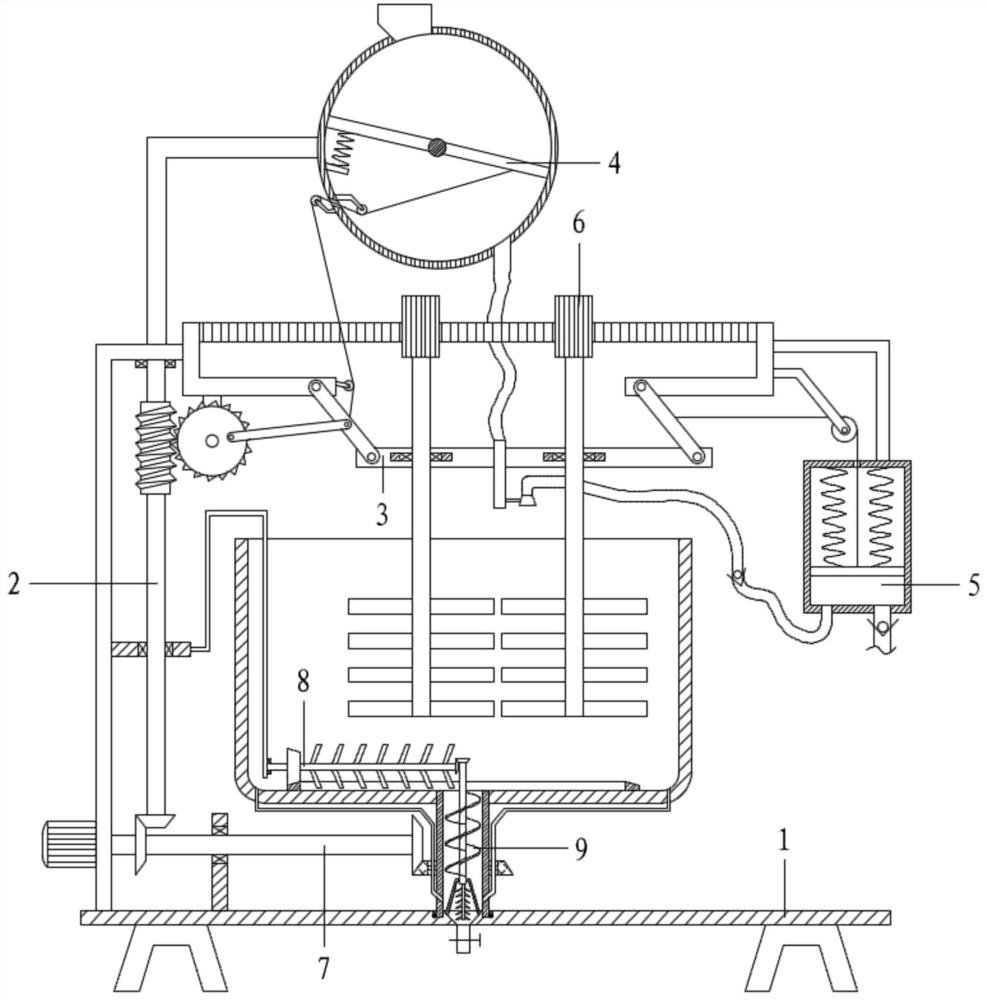

[0072] With reference to the accompanying drawings, a cooling liquid preparation machine for band saw blade grinding includes a frame assembly 1, a drive assembly 2, a preparation assembly 3, a blanking assembly 4 and a liquid filling assembly 5;

[0073] The frame assembly 1 includes a base 101, a foot 102, a mounting frame 103, a first-class pole 104, a raw material box 105, a preparation box 106, a hollow shaft 107, and a drain pipe 108; A mounting frame 103 is connected, and a raw material box 105 is connected to the top of the mounting frame 103 through a type of support rod 104; the preparation box 106 is arranged below the raw material box 105, and the bottom is connected to the base 101 through a hollow shaft 107; the bottom of the base 101 is connected to the corresponding hollow shaft 107 There is a drain pipe 108, and the drain pipe 108 is equipped with a valve;

[0074] Mounting frame 103 is provided with driving assembly 2, and the right side of driving assembly 2...

Embodiment 2

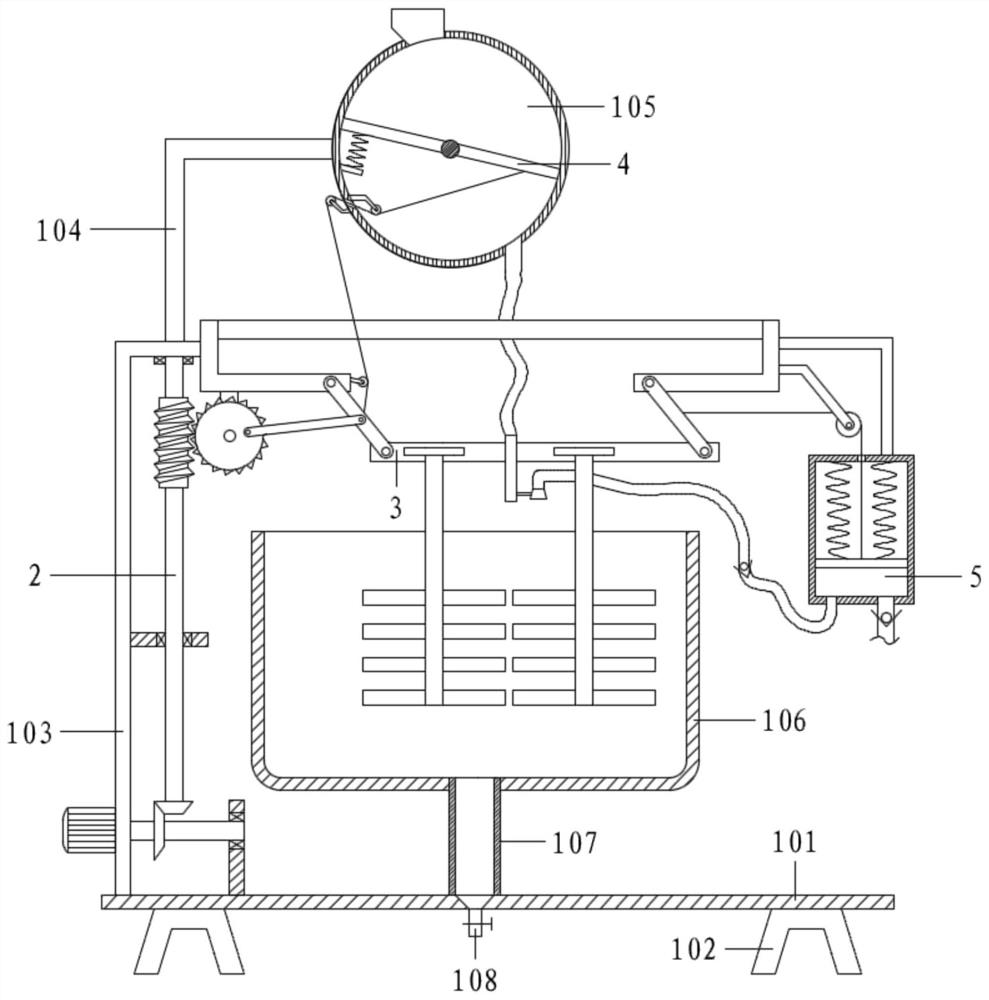

[0076] With reference to the accompanying drawings, a cooling liquid preparation machine for band saw blade grinding includes a frame assembly 1, a drive assembly 2, a preparation assembly 3, a blanking assembly 4 and a liquid filling assembly 5;

[0077] The frame assembly 1 includes a base 101, a foot 102, a mounting frame 103, a first-class pole 104, a raw material box 105, a preparation box 106, a hollow shaft 107, and a drain pipe 108; A mounting frame 103 is connected, and a raw material box 105 is connected to the top of the mounting frame 103 through a type of support rod 104; the preparation box 106 is arranged below the raw material box 105, and the bottom is connected to the base 101 through a hollow shaft 107; the bottom of the base 101 is connected to the corresponding hollow shaft 107 There is a drain pipe 108, and the drain pipe 108 is equipped with a valve;

[0078] Mounting frame 103 is provided with driving assembly 2, and the right side of driving assembly 2...

Embodiment 3

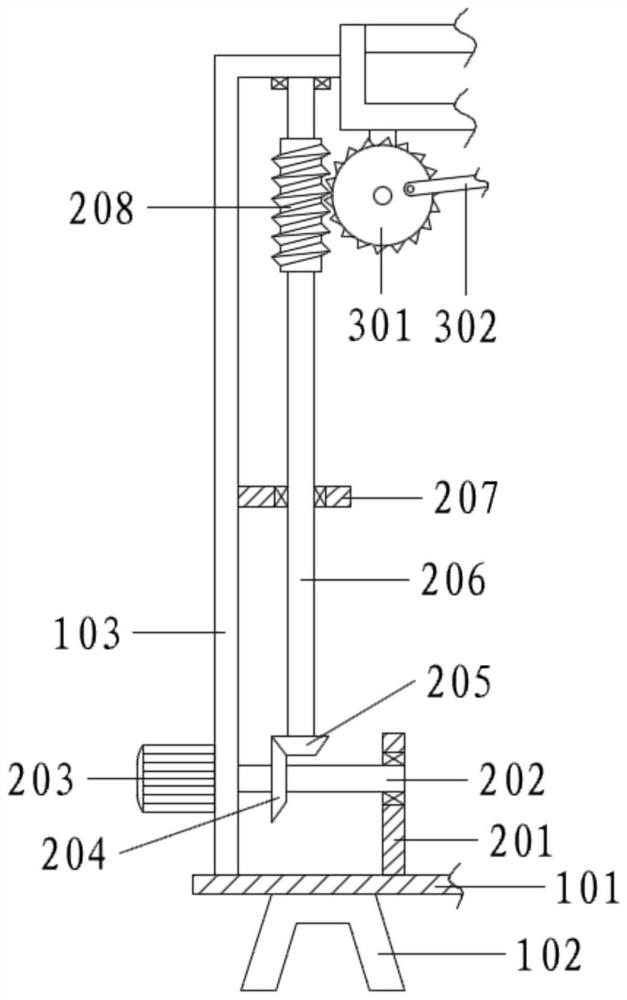

[0100] The difference from Embodiment 2 is that the installation shaft 309 of this embodiment is rotatable.

[0101] It also includes a stirring assembly 6; the stirring assembly 6 includes a rack 601 and a long cylindrical gear 602;

[0102] The front side of the ejector rod 305 is processed with teeth and constitutes a rack 601; the mounting shaft 309 runs through and is connected to the mounting plate 308 through bearing rotation.

[0103] Specifically, when the moving rod 307 moves, the mounting shaft 309 also moves synchronously, wherein there is both left and right movement and up and down movement, so that the long cylindrical gear 602 on the top of the mounting shaft 309 also moves accordingly, and moves with the rack while moving left and right. 601 acts to make it rotate, so that the disturbance rod 310 produces a stirring effect, effectively improving the mixing effect of the preparation; and the long cylindrical gear 602 can also ensure that it still maintains the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com