A tin bath inlet channel for float electronic display glass production

An inlet channel and electronic display technology, which is applied in the field of float electronic display glass production, can solve the problems of small platinum channel outlet width, affecting service life, and exacerbating liquid level fluctuations, so as to reduce platinum damage, prolong service life, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

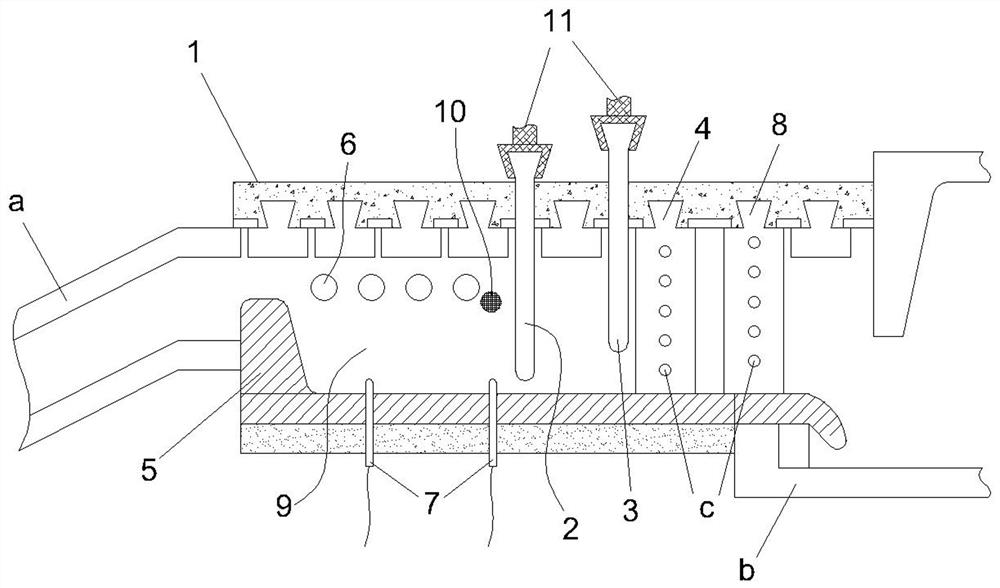

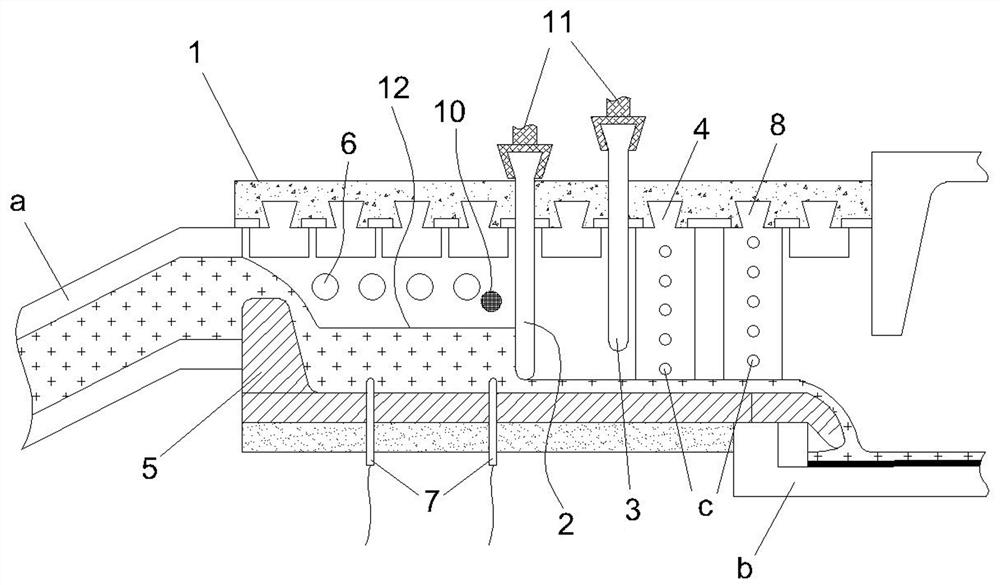

[0018] like figure 1 , 2 As shown, a tin bath inlet channel produced by float electronic display glass includes a tin bath inlet channel main body 1 connected to the outlet of the platinum channel a, and the outlet of the tin bath inlet channel main body 1 is communicated with the tin bath b.

[0019] A baffle 5 is provided at the bottom of the main body 1 of the tin bath inlet channel on the exit side of the platinum channel a. The baffle 5 is a trapezoidal structure with one side vertical and the other side inclined. The side is fitted with the outlet of the platinum channel a, and its top is located in the middle of the outlet of the platinum channel a.

[0020] A group of horizontally distributed silicon carbide rods 6 are fixed in the tin bath inlet channel main body 1 on the right side of the top of the baffle 5 , and a group of thermocouples 7 are pierced through the bottom of the tin bath inlet channel main body 1 under the silicon carbon rods 6 . The said set of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com