A strengthening process of cover glass

A technology of cover glass and tempering furnace, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of uneven distribution of glass plane stress, insufficient strengthening of cover glass, and reduce warpage, so as to avoid The effect of ion volatilization loss, reduction of warpage, and elimination of stress concentration effect

Active Publication Date: 2021-06-04

DONGGUAN JINGBO PHOTOELECTRIC BIT CO

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] In order to solve the problems in the prior art of insufficient strengthening of cover glass (low self-favorable parameters), uneven distribution of glass plane stress, and excessive curvature, the present invention proposes a solution based on the following principles. It can effectively improve the CS (stress value) and DOL (stress depth) of the glass cover of the mobile phone and reduce the problem of warpage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

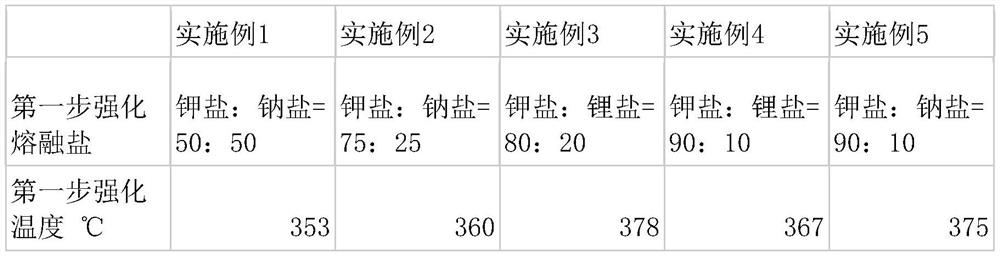

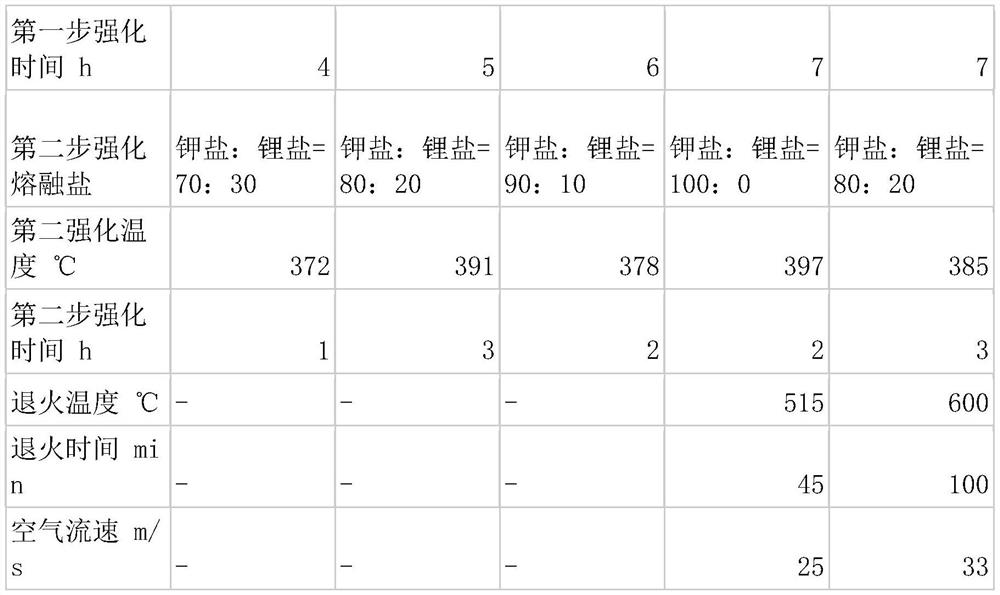

[0039] According to the table below, the cover glass of the present invention is obtained under different technical conditions of ion exchange molten salt composition, ion exchange temperature and time, annealing temperature and time, and quenching air flow rate.

[0040] Table 1

[0041]

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

A method for strengthening cover glass, comprising the following steps: the first step of strengthening: after the surface of the cover glass to be strengthened is cleaned, it is immersed in ion-exchanged molten salt in a strengthening furnace, and the temperature is controlled at 350-380°C , soak for 4-7 hours, and perform ion exchange. The formula of the molten salt is more than one molten liquid of potassium salt, sodium salt, and lithium salt; the second step of strengthening: control the temperature of the strengthening furnace at 370-400 ° C, Immerse the strengthened cover glass in the first step in the molten salt solution whose formula composition is 70-100:0-30 potassium salt:lithium salt in terms of mass fraction, soak for 1-3 hours, and then put it into an airtight container to cool to room temperature to obtain a strengthened cover glass. The stress depth of the strengthened cover glass is 40-65 μm, the surface stress intensity is 800-1300 MPa, the warpage is less than 0.1 mm, and the external dimension expansion rate is less than 2%.

Description

technical field [0001] The invention belongs to the technical field of chemical industry and relates to a strengthening process of cover glass. Background technique [0002] Cover glass (CoverLens), also known as strengthened optical glass, glass window, strengthened mobile phone lens, etc., is mainly used in the outermost layer of the touch screen. Its main raw material is ultra-thin flat glass, which has been cut, CNC carved, thinned, strengthened, After coating, printing and other processes, it has the functions of impact resistance and scratch resistance. The glass itself is very brittle and fragile, and the cover glass is very thin. The Baidu range is between 0.3-0.8mm. If it is not strengthened or tempered, the cover glass is easy to break under a very small external force, which will affect the cover. Further applications of glass. [0003] Therefore, in the current prior art, in order to meet the various environmental performances required by the glass used in mobi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C21/00C03B27/04

CPCC03B27/04C03C21/002

Inventor 刘华

Owner DONGGUAN JINGBO PHOTOELECTRIC BIT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com