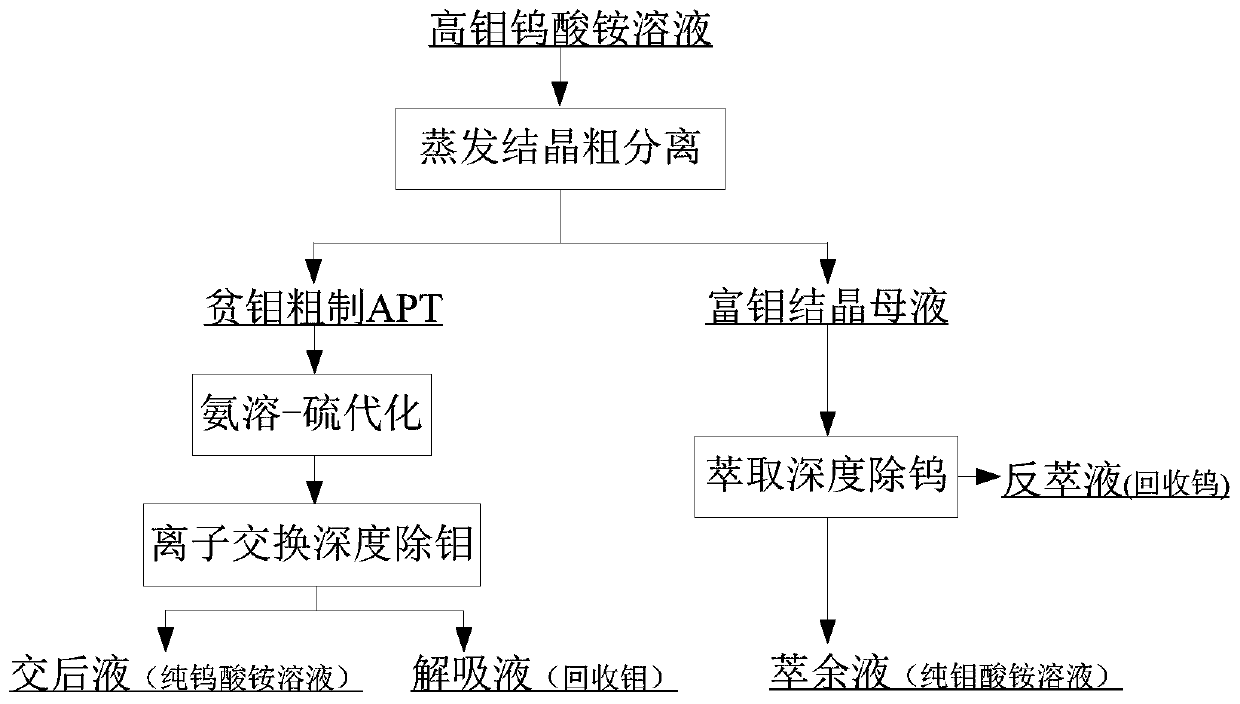

A method for separating tungsten and molybdenum from ammonium tungstate solution with high molybdenum content

A technology of ammonium tungstate and ammonium paratungstate, which is applied in the field of separating tungsten and molybdenum, can solve the problems of increased cost of molybdenum removal, high price, and low proportion of molybdenum product value, and achieve the effect of reducing cost and burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw material solution: molybdenum-containing ammonium tungstate solution, in which WO 3 140.5g / L, Mo 16.3g / L, Mo / WO 3 Mass ratio = 11.6%.

[0046] The first step is rough separation of evaporation and crystallization.

[0047] Take 7000mL of raw material solution and put it into a 10000mL glass reactor, stir and heat in an oil bath to evaporate and crystallize. After filtration, 1180.0 g of crude APT and 2400 mL of crystalline mother liquor were obtained. Crude APT contains 10% water, dry basis contains WO 3 87.2%, Mo 0.76%, Mo / WO 3 Mass ratio=0.87%; crystallization mother liquor WO 3 25.2g / L, Mo 43.7g / L, Mo / WO 3 =1.73, according to crystallization mother liquor, WO 3 The crystallization rate was 93.8%, and the Mo crystallization rate was 8.1%.

[0048] The second step is to remove molybdenum deeply.

[0049] Take 500.0 g of the crude APT obtained in the first step, place it in a 2L stainless steel electric heating autoclave, add 1.5L of 3mol / L ammonia water...

Embodiment 2

[0053] Raw material solution: molybdenum-containing ammonium tungstate solution, in which WO 3 80.0g / L, Mo 40.0g / L, Mo / WO 3 = 50.0%.

[0054] The first step is rough separation of evaporation and crystallization.

[0055] Take 7000mL of raw material solution into a 10000mL glass reactor, stir in an oil bath, heat, evaporate and crystallize, control the temperature between 100±5°C, operate under normal pressure, heat and evaporate for 6 hours, stop evaporation, cool and filter, and obtain 650.8g of crude APT and 2600 mL crystallization mother liquor. Crude APT contains 10.5% water and WO on a dry basis 3 83.7%, Mo 3.37%, Mo / WO 3 =4.03%; crystallization mother liquor WO 3 33.1g / L, Mo 118.4g / L, Mo / WO 3 =3.58, according to the crystallization mother liquor WO 3 The crystallization rate was 87.0%, and the Mo crystallization rate was 7.0%.

[0056] The second step is to remove molybdenum deeply.

[0057] Take 500.0g of the crude APT obtained in the first step, put it in ...

Embodiment 3

[0061] Raw material solution: molybdenum-containing ammonium tungstate solution, in which WO 3 300.2g / L, Mo 16.3g / L, Mo / WO 3 = 5.4%.

[0062] The first step is rough separation of evaporation and crystallization.

[0063] Take 7000mL of raw material solution and put it into a 10000mL glass reactor, stir and heat in an oil bath to evaporate and crystallize. After filtration, 2568.0 g of crude APT and 2100 mL of crystalline mother liquor were obtained. Crude APT contains 10.3% water and WO on a dry basis 3 88.1%, Mo 0.60%, Mo / WO 3 Mass ratio=0.68%; WO in crystallization mother liquor 3 34.2g / L, Mo 47.8g / L, Mo / WO 3 Mass ratio=1.39, according to crystallization mother liquor, WO 3 The crystallization rate was 96.5%, and the Mo crystallization rate was 12.0%.

[0064] The second step is to remove molybdenum deeply.

[0065] Take 500.0g of the crude APT obtained in the first step, put it in a 2L stainless steel electric heating high-pressure reactor, add 1.40L of 4.0mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com