Calcium sulfate gypsum and preparation method thereof

A technology of calcium sulfate and gypsum, applied in the direction of cement production, etc., can solve problems such as waste of resources, achieve the effects of improving work efficiency, good economic and social benefits, and realizing resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides the preparation method of the calcium sulfate gypsum described in above-mentioned technical scheme, comprises the following steps:

[0024] The calcium sulfate gypsum is obtained by mixing the glauberite waste slag and dihydrate gypsum for crystallization reaction and crushing.

[0025] In the present invention, the glauberite waste residue is preferably prepared by a method comprising the following steps:

[0026] The glauberite waste residue raw material is rinsed to obtain the glauberite waste residue. In the present invention, the specific process of the rinsing is preferably as follows: after leveling the glauberite waste residue raw material, rinse it with water for 2 to 3 days, and then dry it naturally to obtain the initial leaching glauberite waste residue; After the waste residue is flattened, rinsed with water for 2 to 3 days, and then air-dried to obtain the glauberite waste residue.

[0027] In the present invention, th...

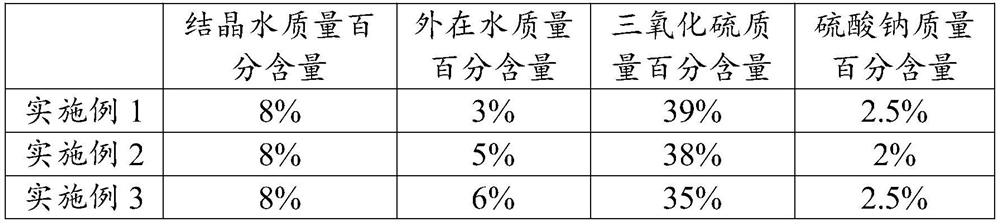

Embodiment 1

[0034] Take 500kg of glauberite waste residue (the mass percentage of sodium sulfate is 5%) and 500kg of fluorogypsum, mix and stir evenly, control the temperature at 60°C for crystallization reaction for 8 hours, and crush it into granules after the end to obtain a particle size of 20-80mm calcium sulfate gypsum.

[0035] The preparation method of described glauberite waste residue is:

[0036] After leveling the glauberite waste slag raw material, rinse with water for 3 days, and then air-dry naturally to obtain the glauberite waste slag for the first leaching;

[0037] After flattening the glauberite waste slag from the initial rinsing, rinsing with water for 3 days, and then air-drying to obtain the glauberite waste slag.

Embodiment 2

[0039] Get 400kg of glauberite waste residue (the mass content of sodium sulfate is 5%), 300kg of fluorogypsum and 300kg of titanium gypsum, mix and stir evenly, control the temperature at 30°C for crystallization reaction for 3 hours, and pulverize into granules after the end, to obtain a particle size of 20 ~80mm calcium sulfate plaster.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com