Magnetic powder modified asphalt mixture and preparation method thereof

A technology of asphalt mixture and modified asphalt, which is applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of large flexibility of orthotropic steel bridge deck, complex stress and deformation pavement, asphalt Improve the road performance and durability, make the preparation process economical and durable, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

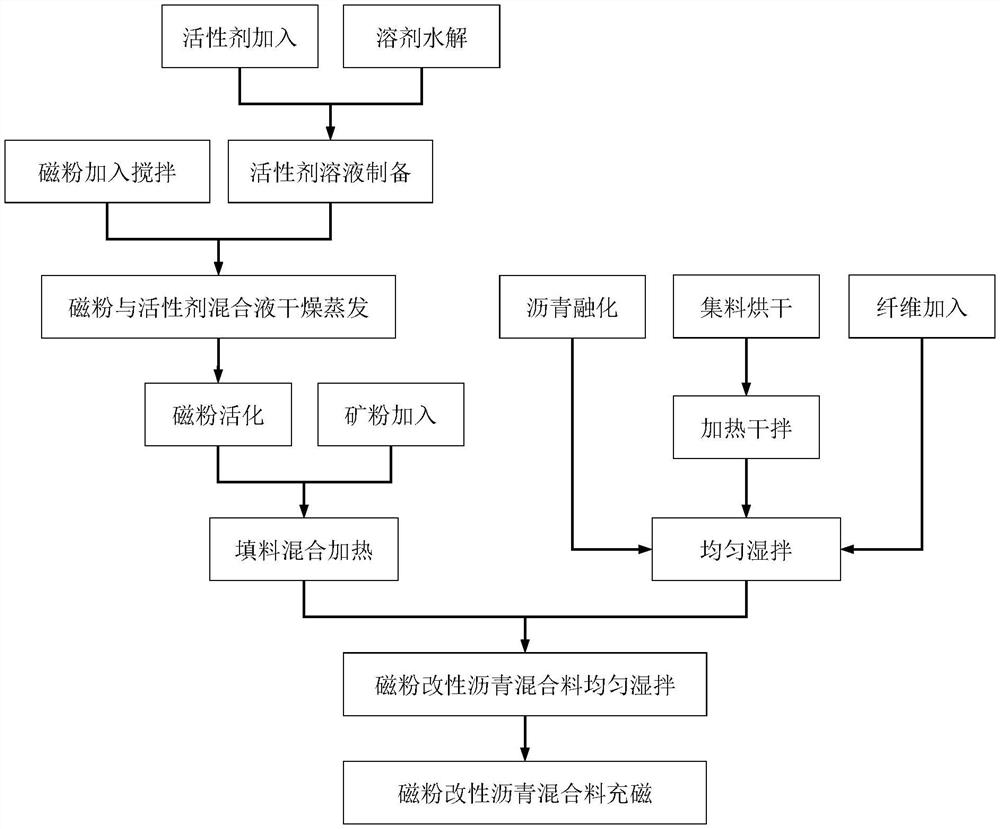

[0032] figure 1 An embodiment of a magnetic powder modified asphalt mixture and a preparation method thereof according to the present invention is shown. The magnetic powder modified asphalt mixture of this embodiment is characterized in that: the gradation type is SMA-10; the selected magnetic powder has a particle size of 100 micron NdFeB magnetic powder; the surfactant is silane coupling agent Si69; the asphalt is SBS modified asphalt; ~5mm and 5~10mm; mineral powder is limestone mineral powder; fiber is lignin fiber.

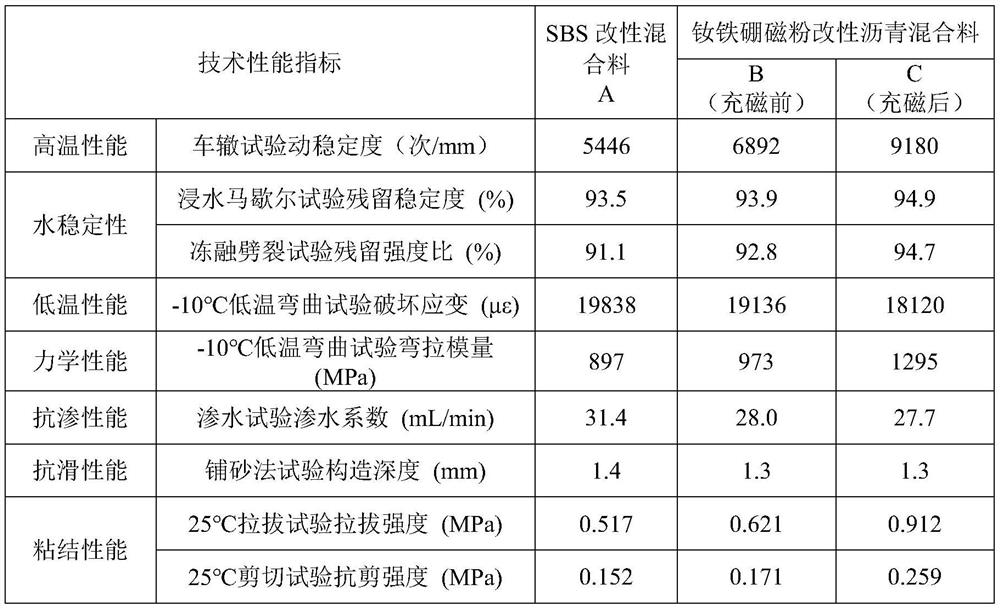

[0033] According to the Marshall test design, the optimal asphalt dosage of SMA-10 is determined to be 6.0%, and 2.0% NdFeB magnetic powder is used to replace the ore powder. At the same time, the performance was compared with the SMA-10 modified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com