Preparation method of waterproof granite-imitated plate

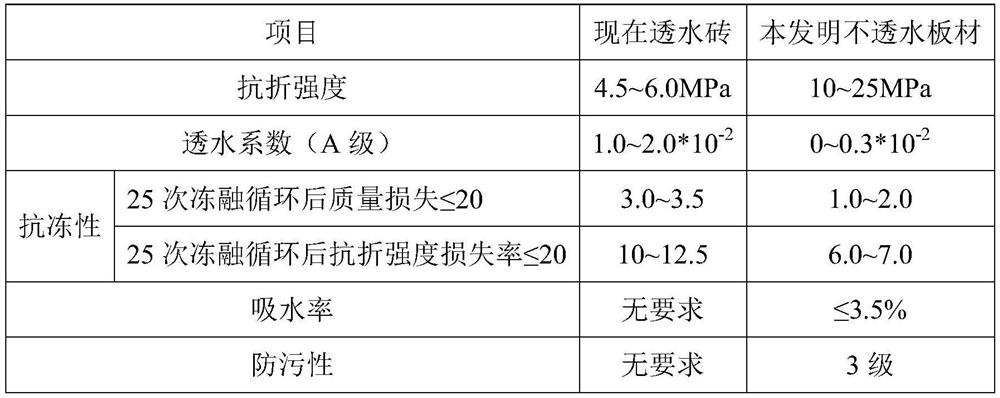

A technology for imitating granite and slabs, which is applied in the field of preparation of impermeable imitation granite slabs, which can solve problems such as difficult cleaning, unsatisfactory decoration, affecting the aesthetics and practical experience of public places, and achieves easy cleaning and antifouling capabilities Strong, not easy to absorb and store dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

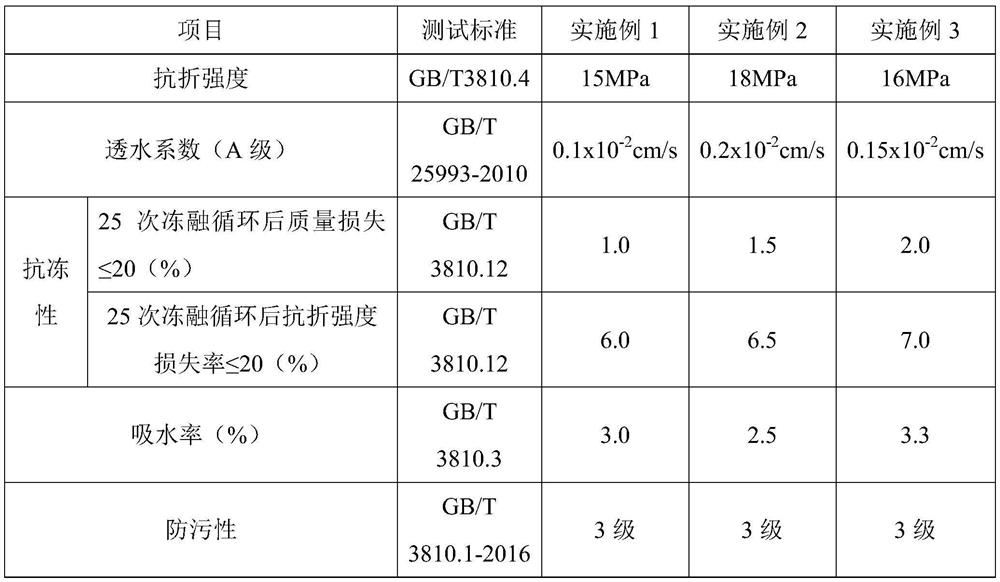

Examples

Embodiment 1

[0022] The preparation method of the impermeable imitation granite plate of the present embodiment comprises the following steps:

[0023] 1) The waste tiles are roughly broken and finely broken, and the tile particles of 10-25 mesh and the tile powder of 25-100 mesh are screened out. In parts by weight, 65 parts of tile particles, 35 parts of tile powder, 14 parts of adhesive, and 6 parts of flux are mixed evenly, and distributed by a distribution machine to form a base material; the thickness of the base material is 3 cm.

[0024] The potassium sodium feldspar is roughly crushed and finely crushed to screen out 12-25 mesh feldspar particles and 30-100 mesh feldspar powder. In parts by weight, 45 parts of feldspar particles, 45 parts of feldspar powder, 16 parts of binder, and 16 parts of flux are mixed evenly, and the fabric is formed on the bottom material through the secondary distribution of the distributing machine. The thickness of the fabric is 1.5cm. . The cloth of ...

Embodiment 2

[0028] The preparation method of the impermeable imitation granite plate of the present embodiment comprises the following steps:

[0029] 1) In parts by weight, mix 55 parts of tile granules, 25 parts of tile powder, 13 parts of adhesive, and 5 parts of flux, and distribute them through a distribution machine to form a base material; the thickness of the base material is 4cm.

[0030] Mix 35 parts of feldspar granules, 42 parts of feldspar powder, 15 parts of binder, 1 part of colorant, and 15 parts of flux, and then distribute them twice through a distributing machine to form a fabric on the bottom material. The fabric thickness of the fabric is 1cm. The cloth of fabric can be made into imitation granite texture according to existing cloth machine cloth.

[0031] In the base material and the fabric, the binder is clay, and the flux is frit powder. The particle size of ceramic tile particle, ceramic tile powder, feldspar particle, feldspar powder is the same as embodiment 1....

Embodiment 3

[0034] The preparation method of the impermeable imitation granite plate of the present embodiment comprises the following steps:

[0035] 1) In parts by weight, mix 75 parts of tile granules, 44 parts of tile powder, 15 parts of adhesive, and 8 parts of flux, and distribute them through a distribution machine to form a base material; the thickness of the base material is 6 cm.

[0036] Mix 56 parts of feldspar granules, 48 parts of feldspar powder, 18 parts of binder, and 18 parts of flux, and then distribute them twice through a distributing machine to form a fabric on the bottom material. The fabric thickness of the fabric is 1.5cm. The cloth of fabric can be made into imitation granite texture according to existing cloth machine cloth.

[0037] In the base material and the fabric, the binder is bentonite, and the flux is glass powder. The particle size of ceramic tile particle, ceramic tile powder, feldspar particle, feldspar powder is the same as embodiment 1.

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com