A kind of preparation method of polyurethane elastomer with low resilience and low compression set

A polyurethane elastomer and permanent deformation technology, which is applied in the field of polyurethane elastomer preparation, can solve the problems of low rebound value and compression set value, so as to reduce the rebound resilience and compression set rate, and change the rebound and compression Effect of permanent deformation and improvement of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

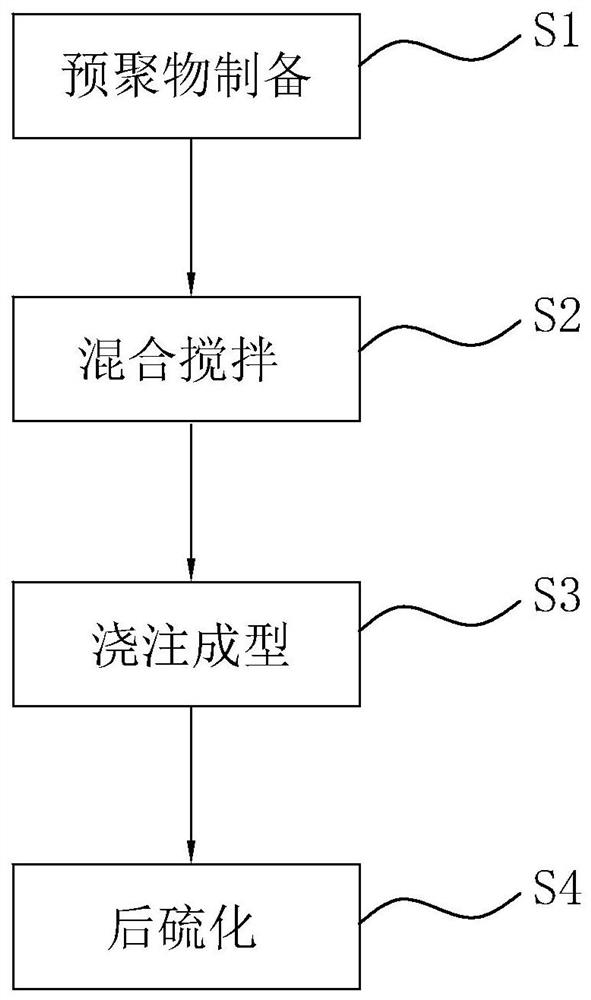

[0038] A kind of preparation method of polyurethane elastomer with low resilience and low compression set, such as figure 1 As shown, the specific preparation steps are:

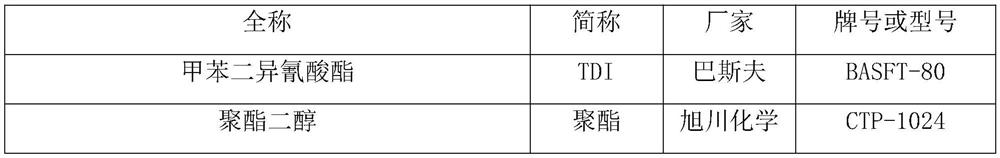

[0039] S1, prepolymer preparation: add polyester diol containing pendant methyl groups and a number average molecular weight of 1000 into the reaction kettle, heat up to 120°C, dehydrate for 2h under vacuum of -0.1MPa, and then cool down to 40°C , contact the vacuum and add it to toluene diisocyanate, the molar ratio of toluene diisocyanate and polyester diol is 1.5:1, the reaction is exothermic until the reaction system is naturally heated to 30min, then slowly heated to 80 ℃, and the reaction is kept for 3h to obtain prepolymer;

[0040] S2, mixing and stirring: the prepolymer, the chain extender, the crosslinking agent, the catalyst, and the colorant are mixed according to the weight ratio of 100:1.9:2.9:0.03:0.5 and stirred at 600 rpm for 30 minutes to obtain a mixture, wherein the cross-linked The joi...

Embodiment 2

[0044] A preparation method of a polyurethane elastomer with low resilience and low compression set, the specific preparation steps are:

[0045]S1, prepolymer preparation: add polyester diol containing pendant methyl groups and a number average molecular weight of 1000 into the reaction kettle, heat up to 140°C, dehydrate for 3h under a vacuum of -0.1MPa, and then cool down to 60°C , contact the vacuum and add it to toluene diisocyanate, the molar ratio of toluene diisocyanate and polyester diol is 1.5:1, the reaction exotherms until the reaction system naturally heats up to 40min, then slowly heat to 90 ℃, and keep the reaction for 2h to obtain prepolymer;

[0046] S2, mixing and stirring: the prepolymer, the chain extender, the crosslinking agent, the catalyst, and the colorant are mixed according to the weight ratio of 100:1.9:2.9:0.03:0.5 and stirred at 600 rpm for 30 minutes to obtain a mixture, wherein the cross-linked The joint agent is a mixture of trimethylolpropane...

Embodiment 3

[0050] A preparation method of a polyurethane elastomer with low resilience and low compression set, the specific preparation steps are:

[0051] S1, prepolymer preparation: add polyester diol containing pendant methyl groups and a number average molecular weight of 1000 into the reaction kettle, heat up to 120°C, dehydrate for 2h under vacuum of -0.1MPa, and then cool down to 40°C , contact the vacuum and add it to toluene diisocyanate, the molar ratio of toluene diisocyanate and polyester diol is 1.8:1, the reaction is exothermic until the reaction system is naturally heated to 30min, then slowly heated to 80 ℃, and the reaction is kept for 3h to obtain prepolymer;

[0052] S2, mixing and stirring: the prepolymer, the chain extender, the crosslinking agent, the catalyst, and the colorant are mixed according to the weight ratio of 100:2.2:3.3:0.1:1 and stirred at 600rpm for 30min to obtain a mixture, wherein the crosslinking The joint agent is a mixture of trimethylolpropane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com