Polyester, preparation method thereof, coating containing polyester, and application of same

A polyester and coating technology, applied in the field of coatings, can solve problems such as difficult handling, and achieve the effect of improving product performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

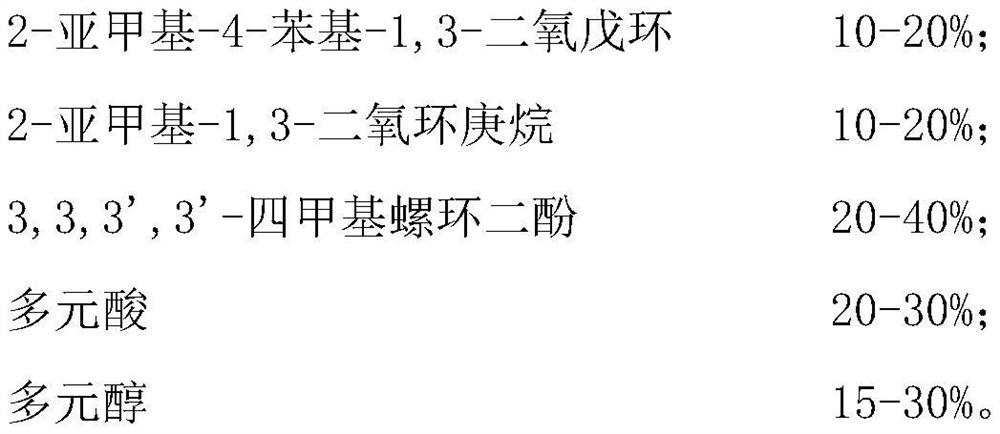

[0029] A kind of polyester and preparation method thereof, comprise each component of following parts by weight:

[0030]

[0031] Wherein the molar percentage of 2-methylene-4-phenyl-1,3-dioxolane is 12%; the molar percentage of 2-methylene-1,3-dioxane is 12% ; 3,3,3',3'-Tetramethylspirocyclic diphenol has a molar percentage of 20%; polybasic acid has a molar percentage of 30%; polyhydric alcohol has a molar percentage of 26%.

[0032] Its preparation method comprises the following steps:

[0033] A. 1.9kg2-methylene-4-phenyl-1,3-dioxolane, 1.4kg2-methylene-1,3-dioxetane and 6kg3,3,3',3' -Tetramethylspirocyclic diphenol and catalyst 14gK 2 CO 3 Put it into the reaction kettle, replace the air with nitrogen to discharge the air, stir and raise the temperature, and react at 160°C-180°C to obtain the hydroxyl-terminated intermediate.

[0034] B. When the by-products of the first step reaction reach the theoretical value, add 3.3kg of terephthalic acid, 1.7kg of isophthali...

Embodiment 2

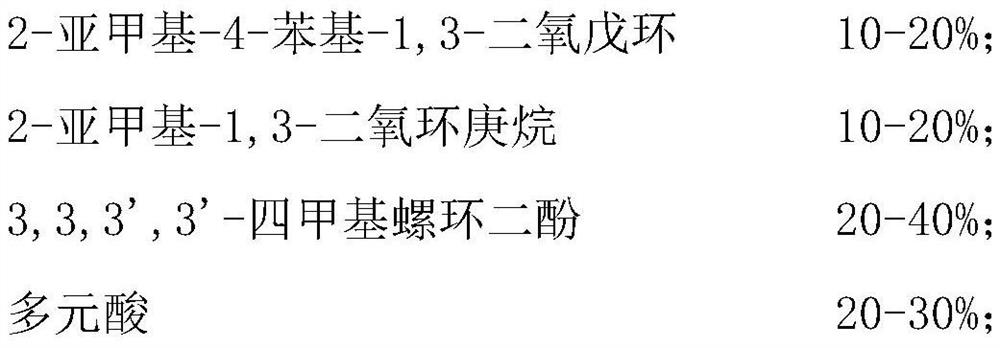

[0037] A kind of polyester and preparation method thereof, comprise each component of following parts by weight:

[0038]

[0039] Wherein the molar percentage of 2-methylene-4-phenyl-1,3-dioxolane is 15%; the molar percentage of 2-methylene-1,3-dioxetane is 12% ; 3,3,3',3'-tetramethylspirocyclic diphenol molar percentage is 30%; polyacid molar percentage is 20%; polyhydric alcohol molar percentage is 23%.

[0040] Its preparation method comprises the following steps:

[0041] A. 2.4kg2-methylene-4-phenyl-1,3-dioxolane, 1.4kg2-methylene-1,3-dioxetane and 9kg3,3,3',3' -Tetramethylspirocyclic diphenol and catalyst 32gK 2 CO 3 Put it into the reaction kettle, replace the air with nitrogen to discharge the air, stir and raise the temperature, and react at 160°C-180°C to obtain the hydroxyl-terminated intermediate.

[0042] B. When the first step reaction by-product reaches the theoretical value, add 1.7kg terephthalic acid, 1.5kg adipic acid, 2.4kg neopentyl glycol and 24g ...

Embodiment 3

[0045] A kind of polyester and preparation method thereof, comprise each component of following parts by weight:

[0046]

[0047]

[0048]Wherein the molar percentage of 2-methylene-4-phenyl-1,3-dioxolane is 12%; the molar percentage of 2-methylene-1,3-dioxetane is 10% ; 3,3,3',3'-Tetramethylspirocyclic diphenol molar percentage is 35%; polyacid molar percentage is 25%; polyhydric alcohol molar percentage is 18%.

[0049] Its preparation method comprises the following steps:

[0050] A. Add 1.9kg2-methylene-4-phenyl-1,3-dioxolane, 1.1kg2-methylene-1,3-dioxetane and 10.6kg3,3,3',3 '-Tetramethylspirobiphenol and catalyst 47gK 2 CO 3 Put it into the reaction kettle, replace the air with nitrogen to discharge the air, stir and heat up, and react at 160°C-180°C.

[0051] B. When the first step reaction by-product reaches the theoretical value, add 1.7kg of isophthalic acid, 1.5kg of adipic acid, 1.2kg of ethylene glycol, 0.8kg of 1,4-cyclohexanedimethanol and 45g of ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com