Regasification system and method for offshore liquefied natural gas

A liquefied natural gas and regasification technology, applied in the field of regasification systems, can solve the problems of low heat that cannot meet regasification heat requirements, high seawater temperature and water quality requirements, and high energy consumption, and achieves low sea movement sensitivity, The effect of improving energy utilization and ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

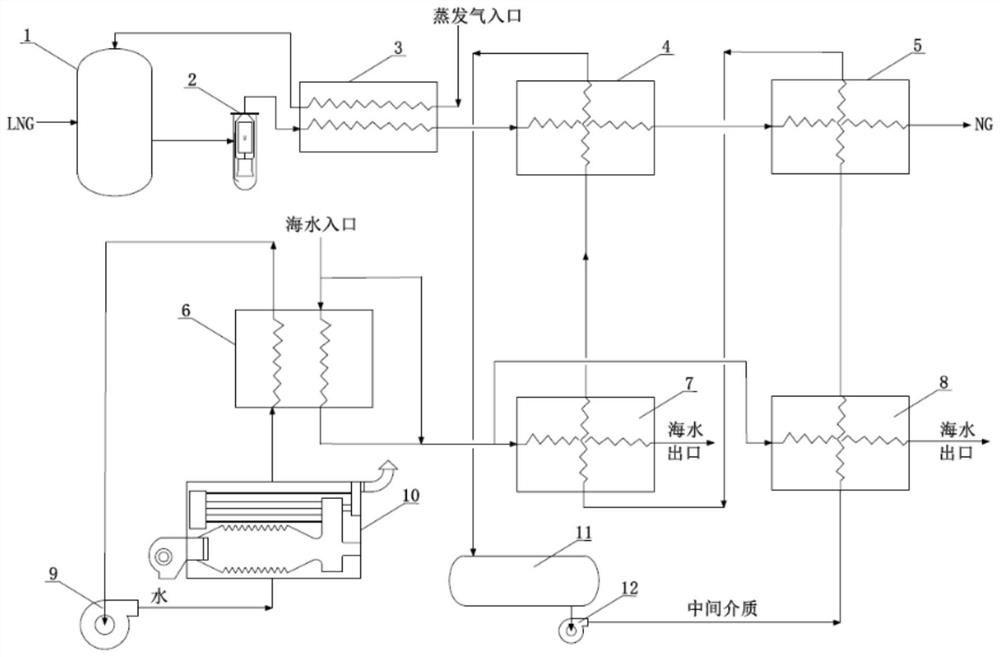

[0029] like figure 1 As shown, this embodiment relates to a regasification system for offshore liquefied natural gas, including:

[0030] LNG system, including booster pump inlet buffer tank 1, LNG booster pump 2, LNG vaporizer 4 and NG warmer 5; the outlet of booster pump inlet buffer tank 1 is connected to the input end of LNG booster pump 2 , the output end of the LNG booster pump 2 is connected to the first inlet of the LNG vaporizer 4, the first outlet of the LNG vaporizer 4 is connected to the first inlet of the NG warmer 5, and the first inlet of the NG warmer 5 The export is a natural gas export;

[0031] The steam system includes a circulating water pump 9 and a boiler 10, the output of the circulating water pump 9 is connected to the inlet of the boiler 10;

[0032] The seawater system includes a seawater preheater 6, the first inlet of the seawater preheater 6 is connected to the outlet of the boiler 10, the first outlet of the seawater preheater 6 is connected to...

Embodiment 2

[0042] like figure 1 As shown, this embodiment relates to a gasification method of an offshore LNG regasification system, comprising the following steps:

[0043] The LNG delivered from the LNG storage device is mixed in the booster pump inlet buffer tank 1 with the BOG cooled in the BOG cooler 3 and returned to the booster pump inlet buffer tank 1, and then sent to the LNG booster pump 2, and the LNG is boosted Pump 2 pumps high-pressure LNG to BOG cooler 3 and then enters LNG vaporizer 4 and NG warmer 5 sequentially. LNG vaporizer 4 vaporizes high-pressure LNG into NG, and then passes through NG warmer 5 Further heat exchange and temperature rise, output after reaching the temperature required for external output;

[0044] The circulating water pump 9 pumps the fresh water to the boiler 10, the boiler 10 heats the fresh water and generates steam, the steam enters the seawater preheater 6 and exchanges heat with the seawater in it to obtain preheated seawater, and the fresh ...

Embodiment 3

[0048] When the seawater temperature is high, the system can use seawater alone as a heat source, and the seawater system does not need to pass through the seawater preheater 6 to directly enter the intermediate medium evaporator 7 and intermediate medium preheater 8, and use the latent or sensible heat of the intermediate medium to realize LNG gasification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com