Method for preparing polylactic acid flexible strain sensor of silver nanowire and application of polylactic acid flexible strain sensor

A technology of strain sensor and silver nanowire, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the limitation of flexible strain sensor preparation and application, harsh processing conditions, difficult strain sensor, etc. problems, to achieve high stability, reduce processing costs, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

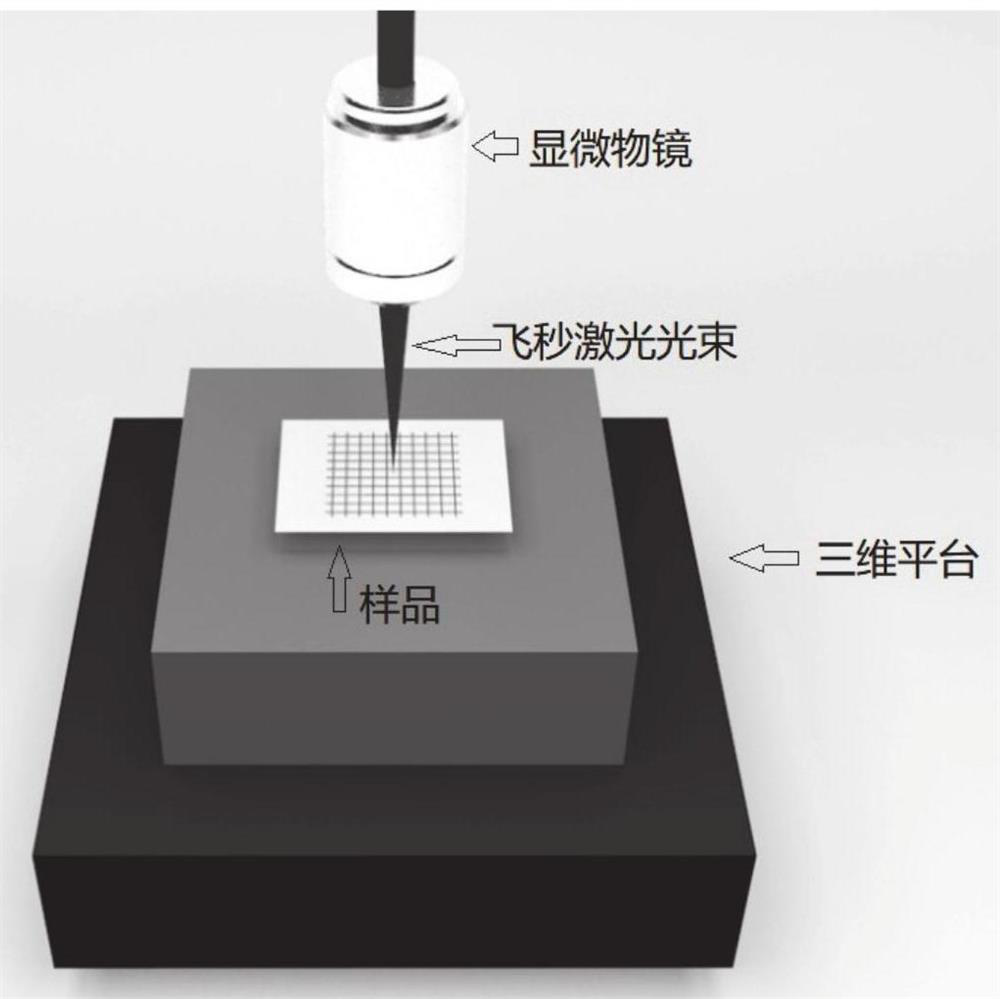

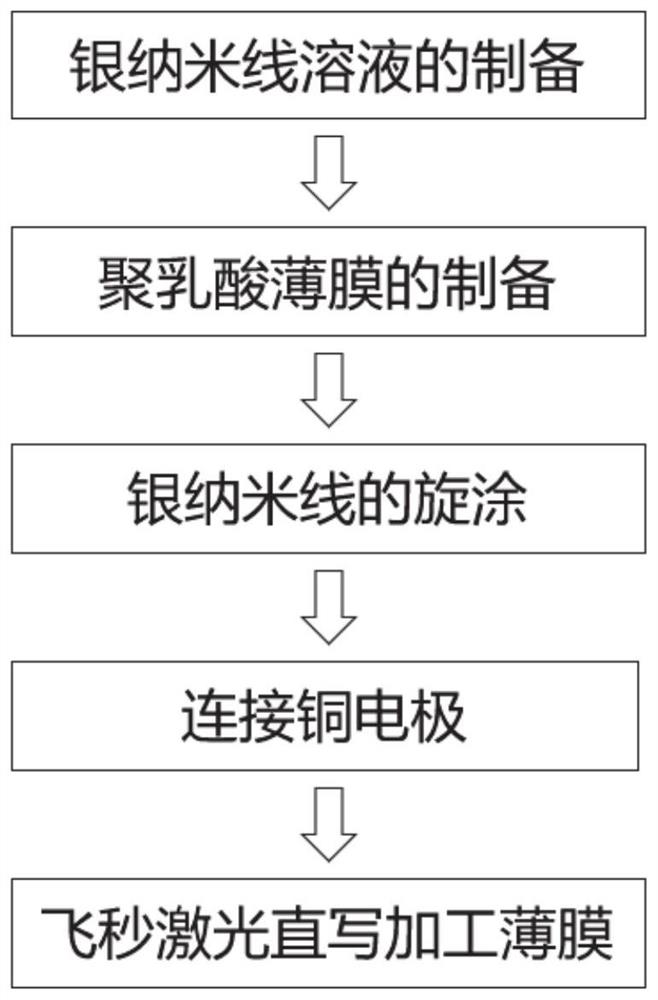

[0041] Such as figure 1 As shown, a method for fabricating polylactic acid flexible strain sensors based on femtosecond laser, the specific steps are as follows:

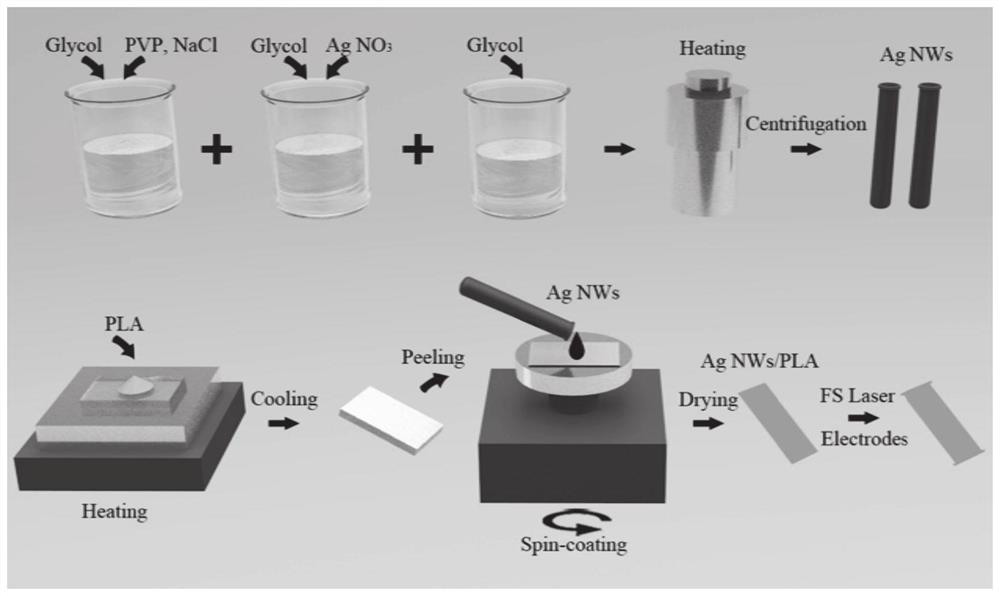

[0042] (1), preparation of silver nanowire solution: add 70ml ethylene glycol (EG) solution to the beaker, then take two parts of 42ml ethylene glycol solution, add 0.672g silver nitrate crystals to one part, and add 0.672g to the other part The PVP and 7mg of sodium chloride crystals were mixed thoroughly in the three solutions and then added to a 200ml stainless steel autoclave for heat treatment at 160°C for 4h. After the reaction, the precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and the final silver nanowire concentration was 2-10 mg / cm 3 . The centrifugation speed is 2000rpm, and the centrifugation time is 5min.

[0043] (2) Preparation of polylactic acid film: First, take about 10 g of 100-mesh polylactic acid particles and place them on a clean and pollution-fr...

Embodiment 2

[0048] A method for preparing polylactic acid flexible strain sensors based on femtosecond laser, the specific steps are as follows:

[0049] (1), preparation of silver nanowire solution: add 70ml ethylene glycol (EG) solution to the beaker, then take two parts of 42ml ethylene glycol solution, add 0.672g silver nitrate crystals to one part, and add 0.672g to the other part The PVP and 7mg of sodium chloride crystals were mixed thoroughly in the three solutions and then added to a 200ml stainless steel autoclave for heat treatment at 160°C for 4h. After the reaction, the precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and the final silver nanowire concentration was 2-10 mg / cm 3 . The centrifugation speed is 2000rpm, and the centrifugation time is 5min.

[0050] (2) Preparation of polylactic acid film: First, take about 10 g of 100-mesh polylactic acid particles and place them on a clean and pollution-free glass sheet, and heat them ...

Embodiment 3

[0055] A method for preparing polylactic acid flexible strain sensors based on femtosecond laser, the specific steps are as follows:

[0056] (1), preparation of silver nanowire solution: add 70ml ethylene glycol (EG) solution to the beaker, then take two parts of 42ml ethylene glycol solution, add 0.672g silver nitrate crystals to one part, and add 0.672g to the other part The PVP and 7mg of sodium chloride crystals were mixed thoroughly in the three solutions and then added to a 200ml stainless steel autoclave for heat treatment at 160°C for 4h. After the reaction, the precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and the final silver nanowire concentration was 2-10 mg / cm 3 . The centrifugation speed is 2000rpm, and the centrifugation time is 5min.

[0057] (2) Preparation of polylactic acid film: First, take about 10 g of 100-mesh polylactic acid particles and place them on a clean and pollution-free glass sheet, and heat them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com