A device for preparing emulsified oil with dispersed phase ultrafine particle size

A technology for preparing equipment and emulsified oil, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large particle size of dispersed phase, large particle size distribution range, poor stability of emulsified oil, etc. Achieve the effect of reducing the particle size of the dispersed phase, uniform particle size distribution, and fine average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

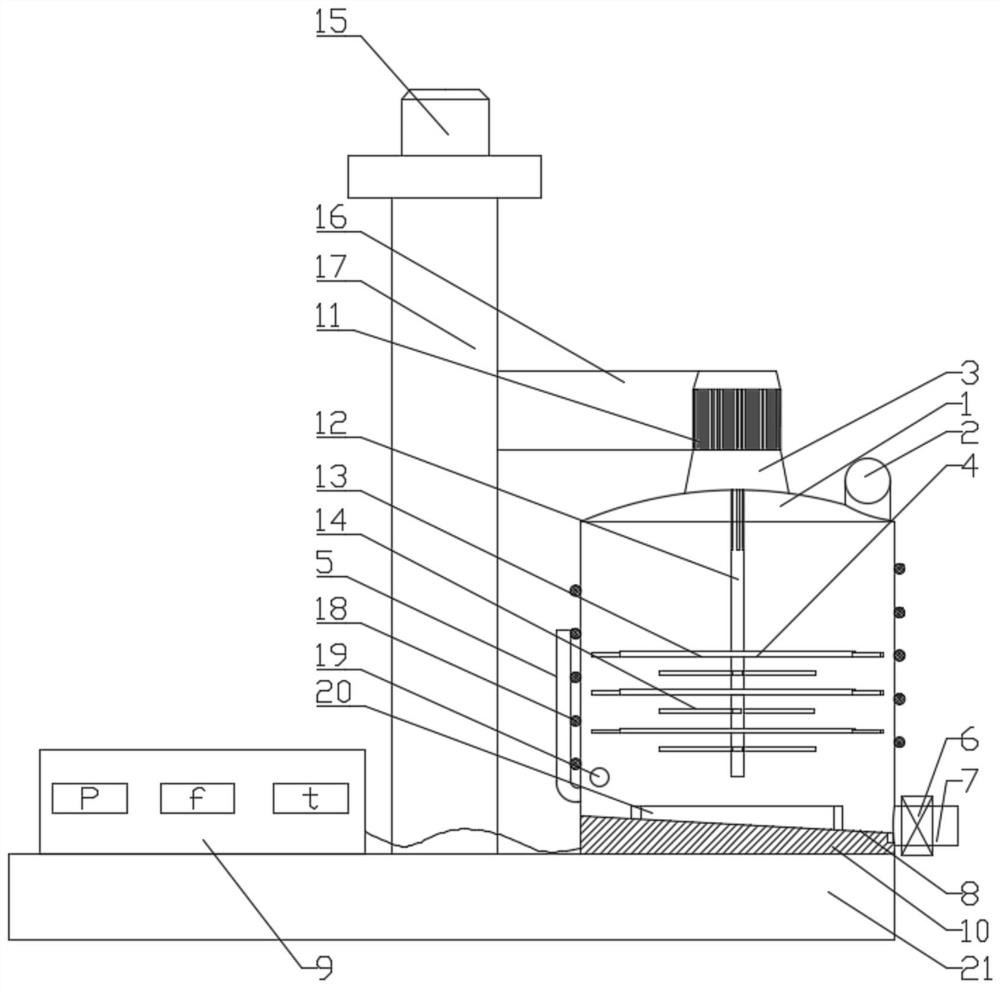

[0031] The invention discloses a preparation device for preparing emulsified oil with superfine particle size in dispersed phase, which includes an emulsification tank, a supersonic emulsification mechanism, a stirring mechanism, a sliding mechanism and a temperature control mechanism.

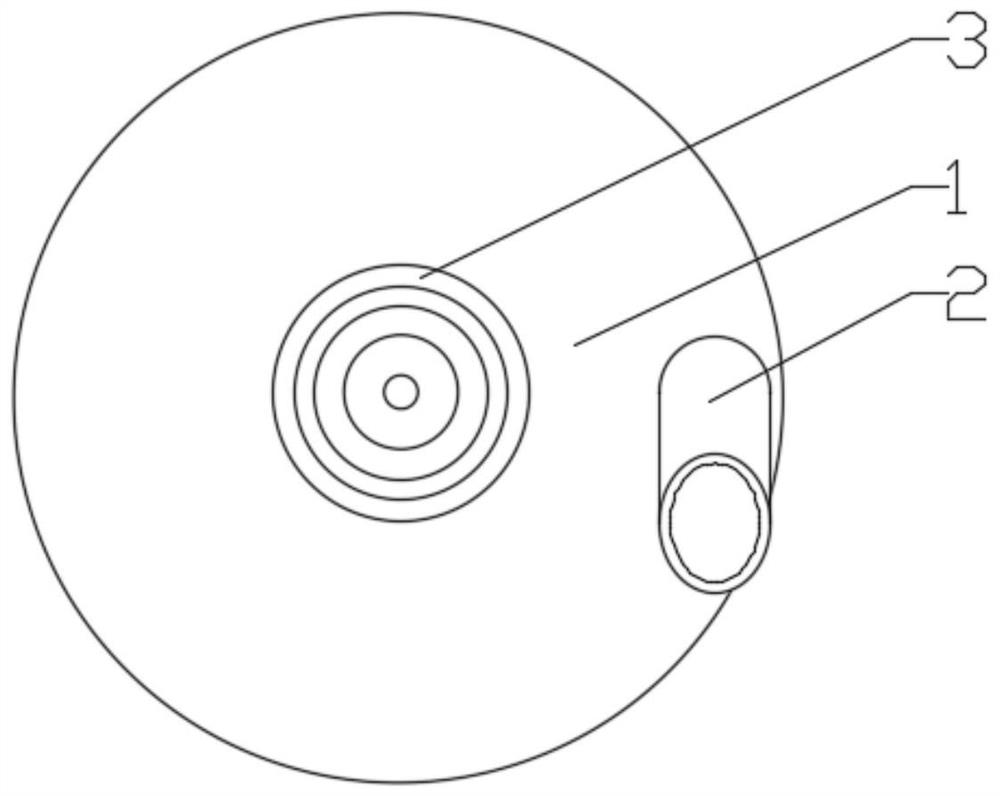

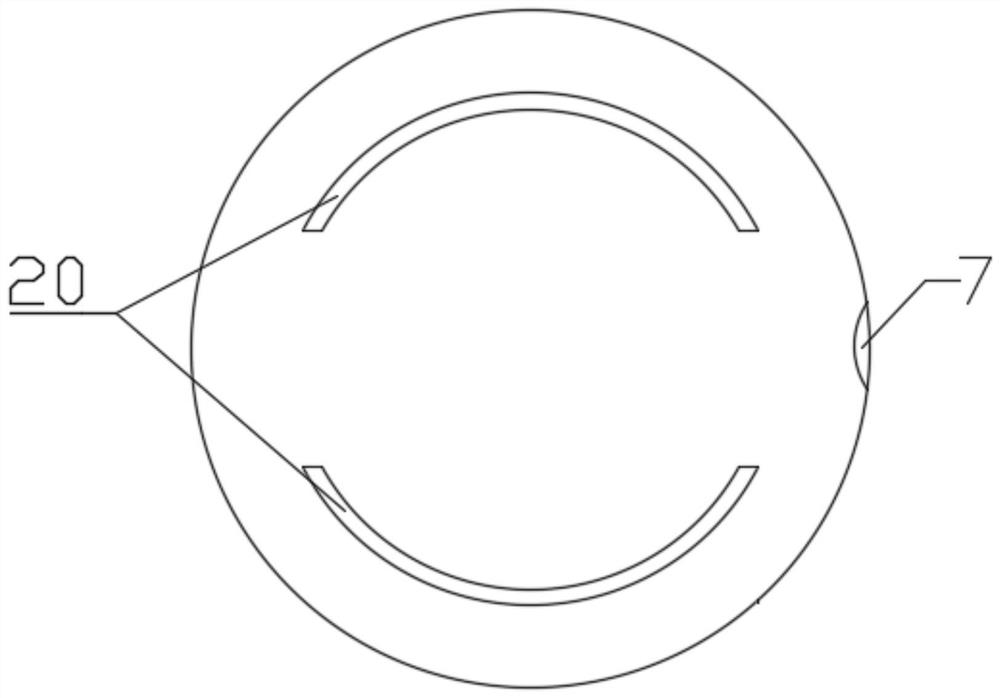

[0032] Such as figure 1As shown, the emulsification tank includes a semicircular tank cover 1 and a tank body 4, a tangential liquid injection port 2 is opened above the semicircular tank cover 4, and a stirring motor support seat 3 is arranged in the center; There is a female rotary LTR type ball spline 301 and a sealing ring 302; one side of the tank body 4 is provided with a connected liquid level gauge 5 to observe the emulsion height in the tank, which can be used as a reference for setting the displacement range of the slider 16; The liquid outlet 7 is opened on the side to collect the emulsion and discharge the waste liquid, and the inclined iron sheet partition 8 with an inclination of...

Embodiment 1

[0054] Span-80 and Op-10 are used as the composite surfactants of water ultra-fine particle emulsified diesel oil in the dispersed phase, and the best hydrophilic-lipophilic balance value HLB is 5-6. The HLB of Span-80 is 4.5, the HLB of Op-10 is 14.5, and the mass ratio of Span-80 and Op-10 is 11.5:1. The emulsified diesel is prepared from the following raw materials in parts by weight: 87.8 parts of diesel, 9.8 parts of deionized water, 2.2 parts of Span-80, and 0.2 parts of Op-10.

[0055] The preparation method of a certain emulsified oil dispersed phase water ultrafine particle size emulsified diesel oil is as follows:

[0056] Add 87.8 parts of diesel oil and 2.2 parts of Span-80 into a beaker and stir until the solution becomes clear; then add 9.8 parts of deionized water and 0.2 parts of Op-10 into another beaker and stir until the solution becomes clear. Pour it into the emulsification tank from the tangential injection port.

[0057] The emulsification temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com