Internal expansion type metal porous adsorption ball and preparation process thereof

A technology of porous metal and adsorption balls, which is applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, and other chemical processes. The effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

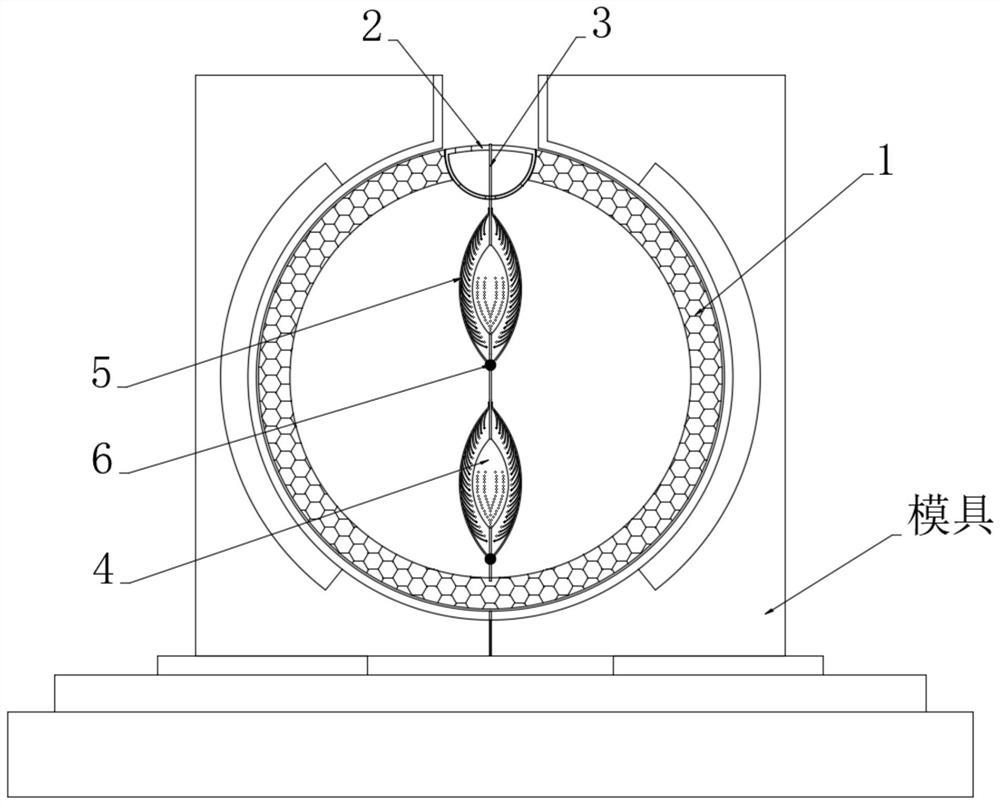

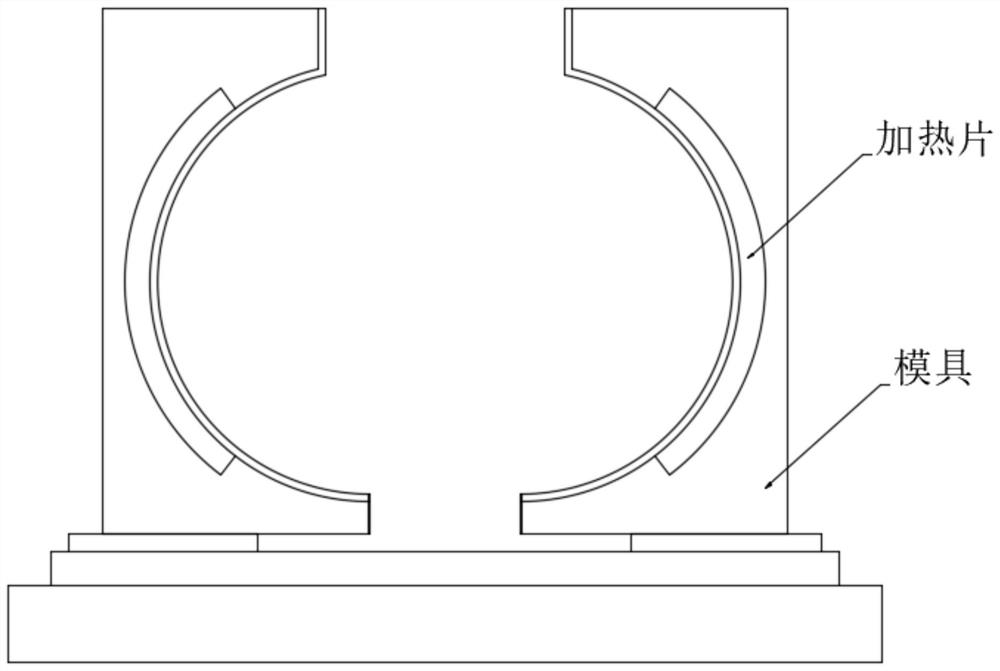

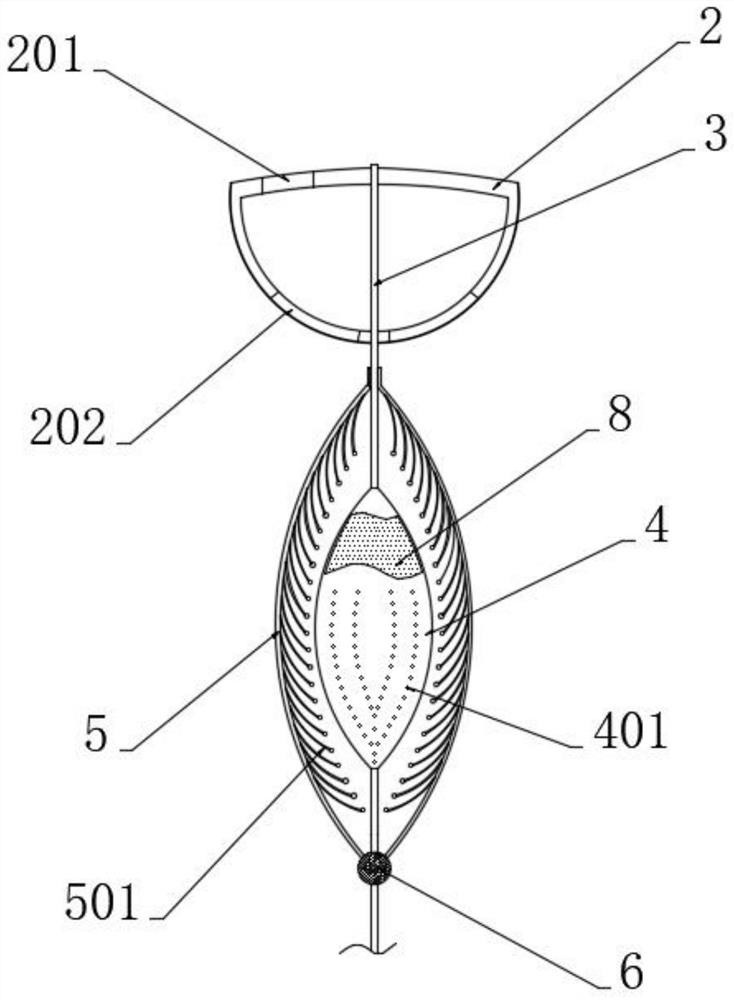

[0036] see Figure 1-3, an internal expansion type metal porous adsorption ball, comprising a hollow ceramic shell 1, the top of the hollow ceramic shell 1 is provided with an elliptical limiting opening, and an elliptical injection nozzle 2 is set at the elliptical limiting opening. 2 is provided with an upper injection port 201 on one side of the top end, and both sides of the bottom end of the elliptical injection nozzle 2 are provided with a lower injection port 202 connected with the interior of the hollow ceramic shell 1, and the upper injection port 201 is connected with an external injection molding gun. The oval injection nozzle 2 is filled with a metal powder mixture 7 for injection molding. The metal powder mixture 7 is composed of metal powder, diatomaceous earth, binder, and water with a mass fraction ratio of 2:1:0.5:3. Through the cooperation of the elliptical injection nozzle 2 and the external injection gun, the metal powder mixture 7 is injected into the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com