Tray-type winding machine and winding production method

A production method and winding machine technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of high transformation cost, difficulty in popularization and application, and high investment cost, and achieve convenient installation and transformation, The effect of simple spinning method and low cost of equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

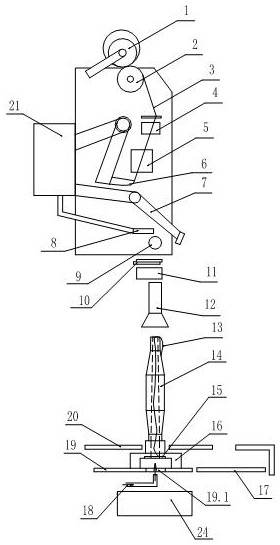

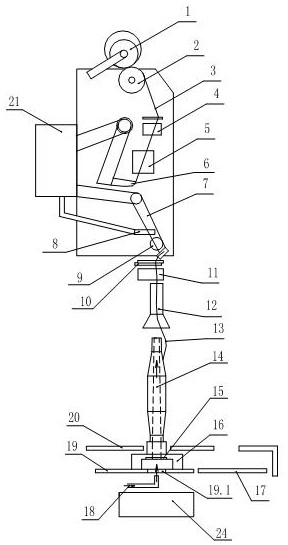

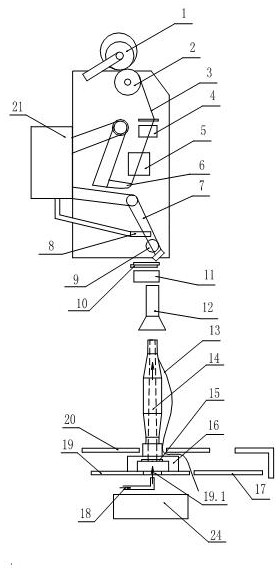

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

[0037] see Figure 5-Figure 6 , an embodiment of a tray-type bobbin winder of the present invention, comprising a single bobbin of the bobbin winder and a bobbin processing device, wherein the single bobbin of the bobbin winder includes a pipe changing device, a negative pressure box 21, a compressed air blowing nozzle 18 and its For the air supply system, a compressed air blow nozzle 18 is arranged below the single spindle unwinding station of the tube changing device, and the compressed air blow nozzle 18 is connected to the air supply system through an air supply pipeline. A negative pressure suction head 22 is set at the single ingot unwinding station, an air inlet and an air outlet are set on the negative pressure suction head 22, the air inlet of the negative pressure suction head 22 is close to the air outlet of the compressed air blow nozzle 18, and the negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com