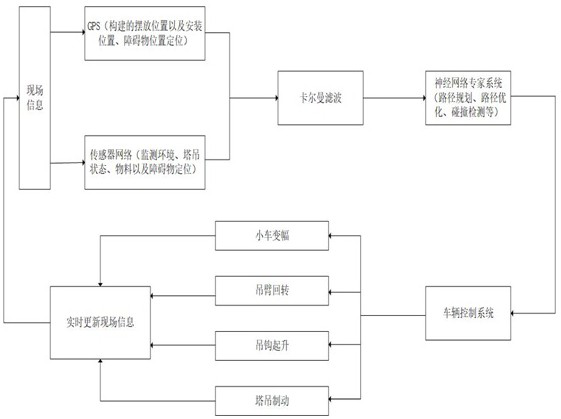

Architecture of unmanned intelligent lifting system

A technology of intelligence and sensing system, which is applied in the direction of radio wave measurement system, satellite radio beacon positioning system, measurement device, etc., can solve the problems of low work efficiency, low degree of automation, high risk, etc., to reduce time consumption, Effects of improving productivity and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

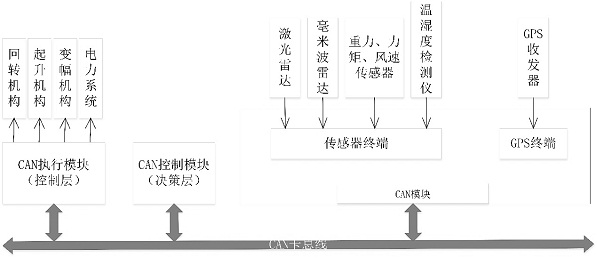

[0031] As shown in the figure, an unmanned intelligent hoisting system described in the present invention includes:

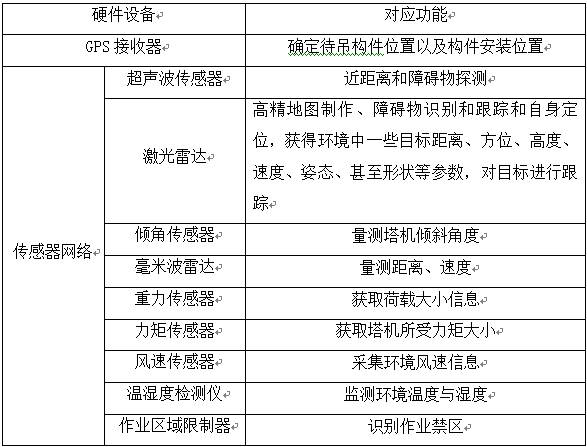

[0032] 1) Perceptual layer

[0033] The main function of the perception layer is perception, which is equivalent to the "eyes" of the system. It is responsible for completing the information collection work of the unmanned tower crane. External information such as environmental wind speed information, and its own position and attitude information such as hook height information, object weight information, luffing trolley amplitude information, and slewing mechanism angle information.

[0034] Specific functions of the perception layer:

[0035] a. Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com